Roundup -- Sludge Treatment

Eco-bricks can reduce sludge disposal in landfills

Sludge disposal may no longer be a problem. Water engineers have found an unusual new use for sludge instead of sending it to waste landfill sites - it is now an ingredient in brick and cement manufacture.

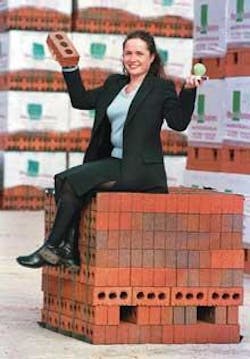

United Utilities has forged award-winning joint ventures with companies in Manchester and Sheffield, England, that blend sludge produced at Arnfield treatment works in Longdendale with other by-products and waste matter. High in mineral content, the sludge is used as a partial replacement for clay by thebrickbusiness Ltd. of Denton, Manchester. Bricks containing about five percent sludge meet British stands for compressive strength, water absorption and durability.

More of the sludge goes to Glacier ARM Ltd of Sheffield, which uses it in cement. The scheme works so well that United Utilities may extend it to other treatment works in the Manchester area.

Describing it as a "win-win" situation for the environment, United Utilities' waste strategic planner Cathy Plimmer said: "Using our sludge means that fewer raw materials are extracted so we and the manufacturers are helping to preserve limited natural resources."

Wilf Burton, works manager at thebrickbusiness commented: "We try to avoid waste whenever possible and recycle 96 percent of waste produced on our Denton site. We use alternative raw materials where there is no adverse effect on quality and bricks made from sludge can be used for any normal purpose."

United Utilities' associates in finding ecological solutions for disposing of waste and by-products, Akristos Ltd. won a Green Apple environment award for the sludge scheme.

United Utilities plc

Warrington, England

Portable sludge gun locates bed levels

The portable Sludge Gun® locates the sludge bed in clarifiers and settling tanks by lowering a probe into the liquid and sending high-intensity bursts of infrared light from an LED across the probe gap to a photo transistor. A solid-state circuit differentiates between liquid and sludge in the gap. The circuit ignores solids suspended in the liquid and continues downward looking for the real sludge bed.

A loud variable pitch horn on the sludge gun howls as the probe nears the sludge, and the pitch and volume of the sound increase as the probe passes through the "cloud" above the sludge and into the sludge bed. By carefully listening to the note, the operator can ignore the solids floating above the sludge and can determine the location of the true sludge level. Sludge levels are read from numbered markers on the cable. Standard cable length is ten metres and extra cable is stored on a spool at the front of the gun.

Using no moving parts, Markland's Series 602 sludge depth meters monitor and control settled sludge levels in gravity clarifiers, lamellar-inclined plate separators and dissolved air flotation thickeners. The patented microprocessor-based instrument can be used as a stand-alone system to fully automate desludging by turning the desludge pump on and off.

Markland's Series 502 suspended solids meters use ultrasonic attenuation to measure the concentration of sludges that are too thick for optical methods.

Markland Specialty Engineering Ltd.

Rexdale, Ontario, Canada

Linings prevent abrasion in screw pumps

Basalt wear-resistant linings protect all types of hydraulic and pneumatic processing and conveying equipment, extending the life of Archimedes-type screw pumps used in the sewage treatment industry. Abrasive solids entrained in wastewater wear away screw pumps and troughs, increasing the annular gap until the conveying capacity of the screw pump reaches almost zero. Abresist pre-engineered basalt linings prevent this abrasion.

The linings accommodate the bending typical of long conveying screws. Pre-engineered tiles are laid to a contour, ensuring a tight and uniform gap between screw and trough. Abrasist basalt lined pipe is used in hydraulic and pneumatic conveying of grit, dried sewage fertiliser, limestone and bottom and fly ash from sludge incineration.

Abresist Corporation

Urbana, Indiana, USA

Pumps handle tough sludges

Models K60 and K63 non-clogging submersible centrifugal sewage pumps handle solids, fibrous material, sludge and other materials found in sewage, industrial wastewater and other contaminated liquids without suffering failure due to heat generation. Both models feature a proprietary motor and pump unit constructed as a single, compact unit set into an air-filled, water-tight casing. The motor handles intermittent and/or continuous operation in wet sump installations. Pumps are available from 1.3 hp to 4.7 hp motor sizes, single- and three-phase, producing flows through 280 gpm and heads of 84 feet.

Pumpex, Inc.

Somerville, New Jersey, USA