Keeping the Mississippi Clean

For municipal water treatment, it's critical that suspended solids are continuously and cost effectively removed from wastewater. For the Lemay Treatment Plant in St. Louis, Missouri, USA, this means utilizing the appropriate automatic, self-cleaning strainer technology as part of its process to remove contaminants and debris from wastewater before returning it to the nearby Mississippi River.

Serving a population of about 1.4 million, the Metropolitan St. Louis Sewer District is responsible for operating and maintaining 9,649 miles of sewers covering 525 square miles of the city of St. Louis. The Lemay plant can ill afford frequent process interruptions, costly downtime and maintenance expenses, as it's the second largest of the district's seven wastewater plants with a treatment capacity of 240 million gallons per day (mgd).

"Our self-cleaning strainers sit off three large 18-inch pipes that feed the entire process water system for the plant," explains Jon Winslow, planner/scheduler for the Metropolitan St Louis Sewer District's Lemay Treatment Plant. "It's critical that the strainers remove solids from the water to protect critical downstream equipment such as spray bars, spray nozzles, wye strainers and tubes in heat exchangers. If the strainers shut down, the plant shuts down."

Historically, some wastewater plants have utilized automatic, self-cleaning single basket strainers, but this design suffers from specific shortcomings. Due to the limited straining area of the media, automatic strainers of single basket design can quickly become overwhelmed and clogged, increasing the pressure differential and initiating frequent backwashes. Plant operators have resorted to resetting the differential pressure switch to a higher set point to prolong the operating cycle between backwashes. But this only accentuates the problem by having to pump at a higher pressure and, thereby, increasing operating costs.

In 2008, as part of its $3.7 billion multi-year Capital Improvement and Replacement Plan to expand capacity to 340 MGD, MSD's LeMay plant installed three new automatic R.P. Adams multiple element strainers.

In addition, because the backwash mechanism of the automatic basket design comes into close proximity to the straining media, large, suspended solids often encountered with raw water can become lodged between the media and the backwash arm causing strainer media damage and/or rupture. Due to inherent design limitations, under high differential pressure conditions, the basket often becomes deformed, further increasing the risk that the backwash mechanism will come into direct contact with the media and cause damage.

"I know of other facilities that have other types of strainers, and through word of mouth we've learned that there's a lot of labor involved with them," says Winslow. "But our multi-element water strainers from R.P. Adams are pretty much maintenance free. They just do their thing and demand very little attention – it's what every plant operator expects in critical process equipment."

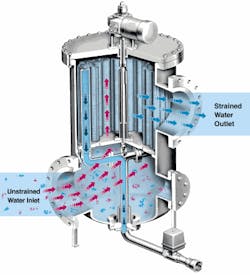

Multi-element, automatic, self-cleaning strainers were first introduced and patented by R.P. Adams in the 1960s, and are now incorporated in over 10,000 installations worldwide. These automatic self-cleaning strainers employ a multi-element, cylindrical wedge-wire design whose tubular elements provide 3-4 times the straining surface area of a typical automatic single basket strainer.

"Each tube is relatively small, but because of the high number of them they have the largest open surface area of any strainer," says Ted Gast, a chemist and general manager at Carl F. Gast Co., a St. Louis manufacturer's representative for industrial instruments and equipment serving customers in Missouri and the adjacent five-state area.

"With the way these strainers are designed, they can operate in a 2-4 PSID range," explains Gast. "The clean differential pressure is maintained until 75% of the open straining area is plugged. Then the differential pressure begins to rise until the backwash set point is reached and the cleaning cycle is initiated. Maintaining a 2 PSID pressure drop over most of the filtration cycle means reduced power consumption from feed pumps which adds up to significant long term savings"

Additionally, the smaller diameter of the media used in the multi-tube strainers at the Lemay plant enables the strainer to safely handle differential pressures in excess of 150 PSIG. This ensures failsafe operation, whereas media found in large basket designs can lead to collapse and failure under differential pressures as low as 35 PSID.

Another significant feature of this design is in the engineering of the backwash mechanism itself, which utilizes a tube sheet to separate the straining media from the mechanism. This prevents the backwash mechanism from coming into contact with the media and damaging the elements due to large solids becoming lodged between the media and the backwash arm.

In 2008, as part of its $3.7 billion, multi-year Capital Improvement and Replacement Plan to expand capacity to 340 mgd, MSD's Lemay plant installed three new automatic R.P. Adams multiple-element strainers.

"The original multi-element strainers from R.P. Adams had been operating for at least 23 years," recalls Winslow. "In all that time, they've worked well and given us relatively trouble-free service, so we decided to stick with the same manufacturer and design for the upgrade... These automatic strainers do what they do and they do it well. Winslow. We get good service out of them."

The National Association of Clean Water Agencies has awarded the Lemay plant a Silver Award five times in this millennium.

Based in Tonawanda, NY, SFC-Adams Inc. is a subsidiary of SERFILCO Ltd. Contact: +1-800-896-8869, [email protected] or www.rpadams.com

More Water & WasteWater International Current Issue Articles

More Water & WasteWater International Archives Issue Articles