Rule engine increases water treatment capacity by 10 percent

VERTIS’ new process control strategy, Gensym’s G2 real-time rules engine, and Siemens’ PCS 7 control system helped a major drinking water company in the Netherlands improve operations and reduce dramatically staffing levels in control operations.

As one of the leading drinking-water companies in The Netherlands, PWN currently delivers water to over 1.5 million inhabitants that consume approximately 100 billion liters of drinking water per year. Like most water companies, PWN faces the challenge posed by a demand for water that varies greatly during the day, while treatment plants operate most efficiently and deliver the highest quality product when they maintain constant output levels.

PWN operates several hundred wells, 25 water treatment and distribution plants, and a large distribution network. Part of the company’s output is produced by pumping surface water into sand dunes and then pumping it up from nearby wells. The water then passes through various treatment processes. Part of the drinking water is produced directly from surface water by complex and highly sensitive processes like membrane filtration or UV/H2O2 treatment. In the 1990s, PWN was the first water company in the world to combine ultra filtration/reverse osmosis technology on a large scale for drinking water production. In 2005, PWN was the first in the world to develop and implement a full-scale single-step UV/H2O2 treatment process.

In the late 1990s, operators worked continuously on a 24-hour, seven-days-a-week schedule at the company’s three main control rooms to adjust production to keep pace with demands, often making adjustments on an hourly basis. This was inefficient because satisfying the highest hourly demand for water requires a huge production capacity. One of the main tasks of the operators was to unlink drinking water demand and production and, by making efficient use of the company’s clean water reservoirs, achieve constant production levels. Theoretically, this will reduce the required production capacity; however it requires a highly accurate estimation of drinking water demand. Estimation errors may lead to drastic adjustments in production rates.

Varying costs of various water sources complicated the challenge. Factors, such as lease contracts and energy costs, affect water costs. In addition, increasingly strict quality demands lead to increasingly complex treatment processes that are more sensitive to changes in production output levels.

Challenge of delivering clean water at a low cost

Each of the company’s facilities is subject to a range of regulations, contracts, and market conditions that affects its operation. The company operates clean water reservoirs that it uses to avoid the need to continuously run at peak demand levels. Demand typically rises to high levels at around 7 am, reaches another peak in the afternoon, and then begins dropping at 10 pm to low levels that are maintained through the night.

Frequent adjustments reduce operational efficiency

One decade ago operators worked continuously at the company’s eight control rooms. Over the past decade, PWN invested in process automation equipment, reducing the number of control rooms needed to three by the late 1990s.

Operators only had a general idea of the future demand so they continuously adjusted production levels in the different plants in order to maintain reservoir levels that they were sure would avoid shortfalls. Frequent adjustments were required to maintain reservoir levels. On the average, the company made more than ten adjustments in production levels in each of its plants during a typical 24-hour period.

Operators had a general idea of the cost of different water sources but there was no time to make the detailed calculations that would have been necessary to optimize production cost. Moreover sudden adjustments to flow levels through water treatment processes can affect drinking water quality.

Because of these difficulties and the fact that new modern water treatment processes require complex control strategies, PWN management made the decision to develop a new process control philosophy. Their goal was to establish centralized - place-independent - control and unmanned control rooms.

“Because we were breaking new ground from an organizational and technological standpoint, it was important to find a consultant with the experience and expertise needed to guide us,” said Antoine Freijters, the manager for operations and water technology for PWN. “We selected VERTIS BV because of their experience in the development of control strategies and because of their strong communications skills, which helped to sell the project to all levels of our organization.”

“One of the main challenges was the tension between the increasing span of control of the operators and their increasing distance from the physical processes on the one hand versus the need for short reaction times in case the process control system requires manual interference,” said Peer Kamp, innovation manager of PWN. “One question was how to design control systems in such a way that process operators, relying on an automatic pilot 99% of the time, will step in effectively when abnormal situations occur? With the help of VERTIS we developed a new process automation philosophy aiming at a uniform and crystal-clear Human-Machine Interface. We discussed ergonomical guidelines, developed a new alarm philosophy, set up a layered structure for process automation and defined a set of software requirements,” he explained.

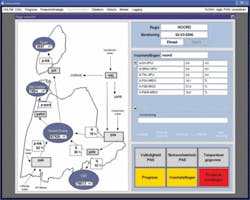

The existing process control system was re-engineered and replaced by a new Siemens PCS 7 control system. The new control system makes it possible to control all of the company’s facilities from a single location. This reduced the number of operators required to control the company’s water production network. The next step was to develop an expert system, a type of rule engine application that captures and deploys human expertise using models, rules, and procedures, to forecast the next day’s demand for drinking water and determine production levels that meet that demand with typically only one set point change per day and only one additional adjustment if needed.

“Our first step was to interview PWN managers, technical staff, and operators to obtain a good understanding of the issues involved in controlling their water production facilities,” said Maarten Wetterauw, project manager for VERTIS. “Our goal was to document all of the issues involved, such as the factors that influence and determine demand, the cost of various water sources, and costs of operating the different plants at various levels, and convert them to mathematical algorithms that would automatically control the operation of each plant. We wanted to greatly reduce the number of changes in production level during the day while ensuring that the company was able to meet its customers’ demand.”

Making use of a real-time rules engine

As they documented the supervisory control logic, VERTIS engineers were faced with the need to select a rules engine platform for expert system development. Wetterauw explained: “The supervisory logic could have been programmed from scratch in C but then it could only have been maintained by the people who programmed it and over time even they could have likely forgotten how it was built. Together with PWN we selected the G2 real-time rules engine from Gensym as the basis for expert system development because it makes it very easy to develop and maintain knowledge rules. G2 provides process engineers with an environment that they can understand so they can easily develop and modify their own mathematical algorithms and knowledge. G2 enables development of the user interface at the same time as the algorithms and provides an offline environment where different control strategies and what-if scenarios can be evaluated. PWN also had a good feeling due to G2’s proven track record in closed-loop expert systems.”

VERTIS developed three primary modules that successfully accomplished the goals of the project. The first module uses trends over the last month, historical data for the day of the week, weather forecasts, district and other information to forecast demand over a 24-hour period. The second module calculates production rates at the company’s five main production sites based on assumptions of available capacity in order to meet this demand while minimizing costs and allowing for only one change in production rate per day. The third module maintains a database of actual capacity, by tracking, for example, equipment that is down for maintenance, and checks the output of the second module to ensure that the production plan does not exceed actual capacity. The modules provide closed-loop supervisory control of the Siemens control system by using the OPC protocol and by accessing historical information in an AspenTech IP21 database using the ODBC standard.

The three modules together are called Plenty® Control. The modules were developed in close cooperation with PWN engineers and operators. The Amsterdam-based IT consulting and services company Illyan was responsible for the G2 programming.

Only one set point adjustment needed per day

Plenty Control runs twice per day, shortly before the 7 am and 10 pm times when production rates are set and maintained until the next time the module runs. Typically the rates only need adjustment once a day at 7 am.

Freijters explained: “By evening out the production peaks that were a characteristic of the previous manual methods, the expert system enables the current facilities to meet a level of demand that is 10% higher than was possible in the past. Providing a similar capacity increase by using the traditional method of building new facilities would cost on the order of US $30 to US $50 million. Taking interest and maintenance costs into account, we thus save over $5 million per year. We have also reduced the number of changes in set points resulting in a more constant water quality.

“Finally, the combination of the application and the new control system has enabled us to reduce the cost of staff in our control room. We reduced staffing from 24/7 at three control rooms to 8 am to 5 pm at two control rooms from Monday through Friday. We are aiming for 8 am to 10 am at two control rooms Monday through Friday. This reduction of 95% saves us roughly $1.8 million per year. As we learn to use the system more effectively, we should be able to make more optimal decisions about sourcing production across our treatment facilities based on costs, which should yield additional cost savings.”

Author’s Note

Jerry Fireman is an independent writer based in Lexington, Massachusetts. For more information, contact Gensym Corporation, located in Burlington, MA, USA. Phone: 781.265.7100, Fax: 781.265.7101, E-mail: [email protected], Web site: http://www.gensym.com