Academic research bridges innovation gap from laboratory to industry

The Cranfield-based Water Innovate Limited is generating award-winning technology that can help wastewater treatment plant operators reduce greenhouse gas emissions by detecting nitrous oxide releases.

The UK-based Water Innovate Limited, a “spin-out” from Cranfield University launched in Spring 2005, has begun releasing products from its portfolio of new water technologies. The research and development company is bridging the innovation gap by providing a conduit for technology transfer out of the laboratory and into the water industry.

Specifically, the company’s N-Tox®, an innovative nitrification toxicity monitoring technique, recently won the SHELL Springboard Award. Its OdourSim®, a dynamic software that models odor formation and emission, is being marketed internationally. Other products in development include ZR-Coag®, a novel high performance chemical additive for water and wastewater treatment, and three advanced tertiary treatment process technologies.

N-Tox

SHELL awarded US$ 70,000 to Water Innovate to help extend the market potential of its proven and innovative N-Tox nitrous oxide monitoring technology. As a result, the company’s plans for commercializing the technology have been given a valuable boost that will accelerate the pace of bringing this technology to the international environmental market.

Water Innovate was one of just three Southern UK Regional finalists out of two hundred and sixty five entries selected to go through to the SHELL Springboard National Final in London, UK. Springboard judges were looking for commercially viable business plans for innovative products and services, which would lead to greenhouse gas reductions.

The patented nitrification toxicity monitor has two complimentary uses; the technology provides an early warning of wastewater treatment works breakdown and, at the same time, helps plant operators reduce greenhouse gas emissions by detecting nitrous oxide release.

Nitrous oxide is an important, but often-overlooked greenhouse gas, with almost three hundred times the global warming potential of carbon dioxide. According to the US Environmental Protection Agency, over four per cent of its emissions arise from wastewater treatment and these discharges are expected to increase significantly as tougher effluent nitrogen controls come into force. Having recognized this issue, Water Innovate invested significant resources in developing N-Tox to enable wastewater plant operators to detect nitrous oxide, thereby helping to reduce greenhouse gas release and mitigate global warming effects.

N-Tox is also used for evaluating nitrification efficiency in industrial and municipal activated sludge systems. As nitrous oxide is an indicator of nitrification failure, the technology can be used to help the direct control of ammonia levels in treated effluent, thereby providing an early warning of wastewater treatment failure.

Water Innovate has advance orders for N-Tox units from major industrial customers under long-term service contracts. The design comprises an integral sample pump, gas conditioning device, non-dispersive IR gas analyzer, auto-calibration system and data logging unit, housed within an IP65 enclosure. The monitor avoids problems associated with probe fouling because it relies on gas-phase detection of nitrous oxide rather than detection of a chemical in the aqueous phase.

Prior research at Cranfield University demonstrated that nitrous oxide is rapidly detected when nitrification starts to fail. The rate of production of the gas is linked to oxygen depletion and ammonia shock loading, and increases in dinitrogen oxide levels are directly related to nitrification failure.

Using N-Tox to detect an increase of nitrous oxide above the start of an activated sludge aeration lane means that at least one hydraulic retention time of the final clarifier would pass before nitrification failure. Figure 1 demonstrates that this time lag, between detection of increased nitrous oxide and the appearance of ammonia, provides typically seven hours warning of nitrification failure.

Once a failure is detected, a number of process options can be followed to restore nitrification including increasing aeration rates, bypassing influent to storm tanks, or returning high ammonia liquors to the works inlet.

The key markets for N-Tox are municipal sewage and industrial effluent treatment. Many treatment works that discharge directly to the aqueous environment are consented for ammonia at less than 5 mg/l. These plants rely on ammonia removal through bacterial conversion to nitrate. Some industrial effluents, such as landfill leachate or pharmaceutical wastewaters, have very high ammonia levels. The requirement for an N-Tox alarm here is critical as the consequences of nitrification failure are more serious.

The N-Tox monitoring system provides an effective alternative to other methods of nitrification failure detection (such as ammonia probes or on-line respirometry) by providing an earlier warning. Plant operators are alerted to problems early so that remedial action can be taken.

ODOURsim

This revolutionary odor emission modeling software package predicts formation and emission of hydrogen sulfide from sewage treatment works. The software produces dynamic predictions that demonstrate variation of emission over time. It can help generate accurate odor contour plots in dispersion modeling packages.

Launched at IWEX in Birmingham, UK, last October, it is now being proactively marketed to water utilities and consultants along with a process modeling service providing specialist in-house expertise. Positive feedback is being received from the marketplace and Water Innovate is currently in the final stages of negotiating a number of significant contracts. The company has employed an additional process modeler to handle the growing workload.

ODOURsim is an essential design tool aiding the development of defensible odor management plans and abatement strategies for existing and planned installations. The product is compatible with existing dispersion models.

The use of dispersion models to predict odor concentrations from sewage treatment works is commonplace. The resulting odor contour plots are often used in support of planning applications, and the models can also be used to make decisions about site-specific odor control technologies.

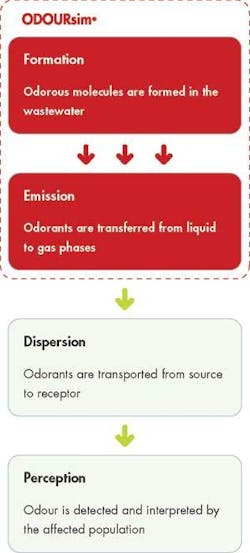

However, it is critical to regard each element in the odor annoyance pathway (see Figure 2) with equal importance. An over-emphasis on dispersion modeling can give inaccurate predictions. ODOURsim was developed because of this over-emphasis and the lack of attention given to inputs to dispersion models.

The software allows the dynamic impact of flow, quality and meteorological variables on emission rates to be examined, avoiding the inaccuracies inherent in using a constant hydrogen sulfide dispersion rate, through mechanistic modeling of variable formation and emission of the gas. ODOURsim employs a liquid-phase hydrogen sulfide model and uses mass-transfer calculations for various process components.

Variations in wastewater flow and quality at a treatment works inlet can lead to significant differences in influent odorant concentrations and emissions from downstream processes. To illustrate these effects, ODOURsim has been used to model a sewer feeding a set of primary sedimentation tanks. The software reveals emission peaks at high flow conditions because the sewer flows full, allowing hydrogen sulfide to form under anaerobic conditions, and because high flows enhance emissions from the sedimentation tank weirs (see Figure 3).

These large variations have implications for when odor measurements are taken. The time of measurement would be crucial if spot measurements are taken, but because ODOURsim is dynamic, the impact on emission rates over time can be predicted. It is essential for emission variations to be included in odor modeling exercises because when significant emission rate variations exist, deviations can radically alter odor footprint.

Current developments

Water Innovate is currently developing ZR-Coag, a product that enables high efficiency coagulation of potable supplies and waste treatment effluents by using special zirconium compounds.

Traditional coagulants are increasingly used in municipal sewage treatment works either to improve the performance of sedimentation processes for suspended solids removal, or to reduce phosphate concentrations to satisfy the requirements of urban wastewater treatment legislation. Zirconium ions are more effective as coagulants because they have a 4+ charge, which is more charge per mole than the 3+ charge of iron and aluminum. Also, they exhibit a lower tendency to dissociate into lower charged intermediates, or complete hydrolysis species, and the higher charge density of ZR-Coag significantly improves the charge neutralization coagulation mechanism, resulting in a requirement for lower dose rates.

ZR-Coag was originally developed with a specific focus on removal of organics from upland waters, but it is equally applicable to other applications including industrial processes that treat effluents or process liquids by using coagulants to aid the removal of organics and suspended or colloidal negatively charged particles. The chemical can also be effectively employed in membrane pre-filtration applications using enhanced coagulation techniques.

Water Innovate is also developing three advanced tertiary treatment technologies. The Membrane Chemical Reactor MC-RTM is an innovation combining UV and titanium dioxide to remove pollutants from high COD and colored effluents. The second technology is the Odor Extraction Membrane Reactor OEM-RTM. It is a new process that will remove odor-causing molecules, with applications in sewage, waste management, and oil and gas sectors. Finally, the Nitrification-Denitrification Reactor ND-RTM is a novel technology for removing nitrogen from wastewater, avoiding the need for chemical additives.

Author’s Note

Steve Callister is the managing director at Water Innovate Ltd. For more information, visit www.waterinnovate.co.uk. Water Innovate Ltd. is run by a management team also comprising Executive Chairman John Catling and Technical Director, Professor Tom Stephenson. Other key staff include Dr. Pascal Harper (Product Manager, ODOURsim®), supported by six academic staff at Cranfield University - Professor Simon Judd, Dr. Simon Parsons, Dr. Bruce Jefferson, Dr. Phil Longhurst, Dr. Paul Jeffrey and Dr. Elise Cartmell.

For further details on Water Innovate please visit www.waterinnovate.co.uk