Roundup: Meters

SmartMeter compatible with all modern AMR systems

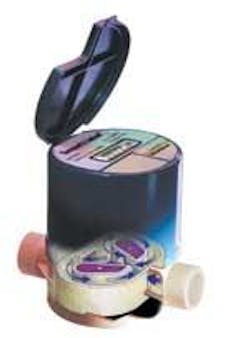

The SmartMeter eliminates problems caused by the presence of sand, grit and air in the water supply that affect the working life and accuracy of conventional mechanical meters. This solid state technology maintains its accuracy under these conditions, says its manufacturer Severn Trent Systems (STS).

The new meter is available as a basic visual read model or in a fully AMR-enabled format. The latter uses advanced communication technology that is compatible with all modern reading systems, including the very latest developments in remote reading through inductive and radio attachments.

The meter uses the proven principal of fluidic oscillation. Water enters the fluidic oscillator through a nozzle that forms an accelerated jet. When the jet enters the flow chamber, it will initially be drawn to one of two diffuser walls. The jet will travel along the wall and then exit the flow chamber. At this point, a small portion of the flow will be caught in the feedback channel and be returned to the base of the incoming jet. This causes the jet to flip to the other side of the chamber, where it will travel along the other diffuser wall, and a small amount of water will be returned via the other feedback channel to repeat the process.

This oscillation between the diffuser walls continues while flow is present and its frequency is proportional to the rate of flow through the chamber. Electrodes placed next to each diffuser wall monitor the oscillation. An electrical current is induced in the jet by a pair of powerful magnets within the flow chamber. The electrodes sense the induced current, from which the rate of oscillation is calculated and thus, over time, a measure of total flow is derived.

Metered consumption can change dramatically; therefore it is customary to re-examine the meter size in each location and match it to water usage. Undersized conventional meters can become damaged while too large a meter will not be sensitive to low flow rates. The SmartMeter eliminates much of the need for regular resizing programmes. It cannot be damaged at high flow rates and it retains a high accuracy across the whole range of its flow capacity.

Severn Trent Services

Chesterfield, Derbyshire, UK

Xenon can reduce meter reading costs up to 90%

Sensus Metering Systems’ Xenon product range maximises the advantages of Short Message Service (SMS) technology by offering the potential to reduce meter reading costs.

Xenon is a “plug and play” GSM memory-reading device that links to water and heat meters and provides automatic SMS transmission of data to a web server. This information can then be exported to advanced management information systems. In addition, Xenon can issue alarms to devices, such as mobile phones in the case of leakages, a broken pipe or unauthorised access to the meter.

According to Richard Jeffers, the technical manager for Sensus Metering Systems, Xenon is managing data from more than 12,000 metering applications in Europe. “The technology has the potential to redefine meter reading in remote locations and to reduce associated costs dramatically,” he said. The US-based company is now launching its remote reading technology in the UK.

Jeffers continued: “In effect, Xenon eliminates the requirement for regular manual ‘walk-by’ or visual meter reading arrangements; instead Xenon communicates directly with pulse output or encoded meters and transmits data to an internet server using GSM technology. From there, the information can be exported for analysis and billing - or sent to a mobile phone or email account if preferred. It is also possible to transfer the data automatically to a billing system via ODBC.”

In certain applications, Xenon could reduce the cost of meter reading by more than 90% when compared to conventional “walk-by” applications, claims the company.

Sensus Metering Systems

Raleigh, North Carolina, USA

Meter design creates larger bandwidth

The Optiwave 7300 C Radar Level Meter measures distance, level and volume of liquids, pastes and solids. Its design offers a maximum measuring range of 40 metres, enabling it to operate with a larger bandwidth for sharper resolution. The higher signal dynamics of the Optiwave 7300 C allow the detection of the smallest level changes and clearer location of the product’s true surface.

Installation and set-up of the meter requires that the user fit the gauge to the tank, wire it and turn it on. The device will then run a self-diagnostic test to ensure proper operation. Optiwave’s Set-Up Wizard subsequently takes the user through a simple series of questions to define the tank and the product to be measured. The device offers four types of screen displays: alphanumeric, alphanumeric with tank illustration, alphanumeric with bar graph and signal screen.

Krohne, Inc.

Peabody, Massachusetts, USA