Water treatment piping systems pass the acid test

By Scott Robichaud

Photo by Asahi/America Inc.

Over the past several years, many water treatment plants in the southeastern and midwestern United States have faced troubles with existing piping systems that used sulphuric acid as a chemical dosing method. Pipeline damage, leaks, joint failures, chemical spillage and down time have been caused by a decrease in availability of low concentration acid (in the range of 93%).

Piping manufacturers have responded by using a thermoplastic material, but sulphuric acid applications will eventually create stress cracks in these pipes. One solution to this problem is the use of Halar® piping systems, manufactured by AGRU, that is more resistant to sulphuric acids than other plastics.

Increasingly, the preferred method for treating water uses reverse osmosis (RO) membranes. This method is commonly used in regions where water is considered brackish, having a light salt content, as RO technology is a superior method for removing salts from the water supply. However, scaling is a common challenge for plants using RO membranes. Scaling is the build-up of salts on the membrane, which greatly reduces functionality and eventually causes failure. Common scales include silicates, sulphates, phosphates and carbonate. Calcium carbonate is the most common scale in areas where the water is brackish.

Scaling elimination is best accomplished through prevention because they can be very difficult to remove once they begin to build up. Several methods prevent scale formation, including lime softening, ion exchange, acid dosing and anti-scalant chemical dosing. Chemical dosing is a cost-effective method that has proven to be simple to operate and reliable, although each method has advantages and disadvantages.

In chemical dosing, sulphuric acid in concentrations from 93% to 97% is dosed into the main feed water line prior to the membrane facility. The acid is generally gravity-fed or pumped at low pressure to day tanks. From the day tank, acid is pumped at high pressures to inject into the feed water supply, prior to the membrane plant.

Most plants specify 93% sulphuric acid for the treatment. A typical plant serving 140,000 people will use about 1,600 to 1,900 gallons of acid per day. The piping materials most commonly used to convey and inject the acid are carbon steel or polyvinylidene fluoride (PVDF). Carbon steel has many drawbacks, including maintenance requirements, which make it less attractive for plant owners; therefore PVDF thermoplastic piping, which features excellent chemical resistance to most acids, is widely used. It is generally available as a single-wall or double-contained piping system.

In certain US regions, 93% sulphuric acid has decreased in availability. The acid is readily available in 98% concentrations, as this concentration is a by-product of phosphate production. The reduction in availability of 93% acid, combined with the cost savings of using the more common 98% acid, caused many facilities to switch their acid supply from 93% to 98%. Many facilities running PVDF piping systems assumed that this acid would not cause any problems in their pipelines.

In various sites, piping systems failed within three to six months of changing to a higher concentration acid. The culprit of the failure was neither the piping material nor the sulphuric acid. In concentrations of 98.3% or higher, sulphuric acid has a natural contaminant, known as sulphur trioxide (SO3), which acts as a stress cracking agent for PVC, C-PVC, PP and PVDF materials.

Sulphuric acid with a concentration of 98% is typically supplied in a concentration range from 98.1% to 98.9%. This has led to the new common terminology of 98+% sulphuric acid.

This 98+% sulphuric acid (with SO3) attacks PVDF pipe and steel pipe. Failure in steel pipe comes in the form of hydrogen grooving of the pipe wall surface. In most applications, sulphuric acid will wear away steel pipe at a rate of 0.02" per year; however the formation of tiny hydrogen bubbles in the media will create grooving on the pipe's inside surfaces, creating deeper wear and quicker failure with weep holes. Maintenance programs and regular material inspection are required when using steel for sulphuric acid applications.

Carbon steel can be used in a sulphuric acid application, since the material forms a protective film of iron sulphate, which slows the corrosion process, but this process forms hydrogen gas, which can actually "scrub" the iron sulphate off the pipe surface, leaving it vulnerable to chemical attack.

During normal flow periods, hydrogen is in the flow of the media and is not troublesome. Hydrogen accumulates during stop and start conditions, in 90° elbows and weld gaps. When the process starts again, the hydrogen is pushed along the surface, wearing away the protective layer. Once the layer is removed, the steel will be readily attacked until the iron sulphate layer can be reformed.

Many thermoplastic materials will stand up to sulphuric acid applications; however the presence of SO3 will create stress cracks in the pipe material. These are normally small longitudinal cracks, one to two inches, through the pipe wall.

A copolymer of ethylene and chlorotriflouroethylene (E-CTFE), commonly known as Halar®, can solve these problems. This material has been successfully tested and used in sulphuric acid and sulphur trioxide applications.

Since the availability of 93% sulphuric acid has proven to be in a shortage at times, piping systems must be capable of accepting all concentrations of acid, from 93% to 98.9%. Halar piping systems are generally more expensive than PVDF systems, however 98% sulphuric acid is approximately 20% less expensive than 93%, depending on the supplier. A typical plant serving 140,000 residents will use 1,600 gallons of 93% acid per day. Switching to 98% acid will reduce consumption by roughly 4%; therefore a typical plant can save more than US$35,000 per year by using Halar piping systems with a higher concentration of sulphuric acid. Table 1 depicts results from a cost study further illustrating this point.

Photo by Asahi/America Inc.

Piping design and installation method must be carefully considered in addition to selecting the proper piping material, which is critical for smooth operation in water treatment plants. For best results, the piping system supplier should be involved in these recommendations.

Government regulations and required protective measures may help determine the design and installation. Piping is both above grade and below grade. Above grade piping has a single wall configuration; bowever it must be double-contained using a double wall configuration to protect groundwater when running the pipe underground. This is a US Environmental Protection Agency (EPA) guideline, according to the Code of Federal Regulation, 40 CFR 280. In pump houses where sulphuric acid is pumped to higher pressures of 60 to 100 psi, pipe is commonly placed behind protective plastic doors for safety reasons.

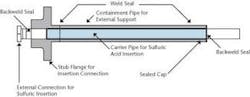

Other design considerations involve determining the most effective and efficient methods to inject acid into the main water supply. One way is to apply through an injection well used in chemical dosing. An injection quill can be used to inject the chemical into the centre of the pipe, creating a better blend of acid in the water. Figure 2 shows a drawing of an injection quill. During periods of interruption to the acid feed, water will flood into the injection line, creating an exothermic reaction as high as 180°F to 200°F in the pipeline. Check valves should be used to prevent water back flow and minimise thermal stress.

When making the final decision on which piping material to choose for chemical dosing applications, it is important to consider a material that provides low maintenance and, more importantly, chemical resistance to all grades of acid that could be used over the life of a facility. Halar piping systems provide safety, reliability and cost savings to municipal water treatment facilities, given its resistance to sulphuric acid and the common contaminant of SO3. Its chemical resistance surpasses that of other plastics such as PVC, PP and PVDF, and will provide virtually maintenance-free service for at least 10 years.

Halar is installed in many water treatment RO facilities that use sulphuric acid to prevent scaling on membranes. HALAR™ is a registered trademark of the Solvay Solexis Company.

Author's Note

Scott Robichaud is the executive vice president at Asahi/America, Inc. located in Malden, Massachusetts, USA. For more information, visit the Products Section of the website: http://www.asahi-america.com, which includes information on the product Ultra Proline.