Optimal performance requires Triple A

By Markus Busch, Mark Huschke, Ian Lomax

Knowing the active membrane area of a reverse osmosis (RO) element is critical to ensuring the optimal design and performance of a desalination system. Research shows, however, that significant discrepancies between some elements' nominal (stated or implied) membrane area and their actual active membrane area exist. These discrepancies often result in unintended effects on concentration polarisation, fouling behaviour and other aspects of system operation.

By contrast, accurate representation of active membrane area results in accurate design guidelines, which allow for accurate design flux and more efficient systems with fewer fouling problems and lower operation costs.

The discrepancy between nominal and actual active area is most pronounced in elements that are constructed via conventional, manual techniques, while elements that are constructed via automated techniques exhibit the most accurate nominal areas. In either case, a physical examination, or autopsy, of any given element can be conducted to determine how closely its nominal area matches its actual active area.

Define active area

As original equipment manufacturers (OEMs), consultants and end users have gained experience in the operation of RO elements in various applications and locations, many now include in their specifications a limit on the average permeate flux (APF) - expressed as litres per square meter per hour (L/m2h), or gallons per square foot per day (gfd) - at which systems may be designed and operated.

But to accurately calculate the APF of any membrane system, the actual area of useful membrane surface area in each type of element used must be known. This "useful area" is known as the active membrane area and is defined as the available surface area of membrane within an individual element, or within a system, through which permeate can pass.

Active membrane area differs from total membrane area and nominal membrane area, as follows:

• Total membrane area is the area of the membrane actually used in the construction of an RO element before trimming, gluing and rolling, and is not normally stated by the element manufacturer.

• Nominal membrane area is a value given or implied by the element manufacturer as the membrane area in any particular element type or configuration. The nominal area is a non-standardised measurement and does not always accurately reflect the actual active membrane area of an RO element.

• Active membrane area is the actual, measured area of useful membrane when an element is opened and the area is measured and calculated leaf by leaf. The difference between active and total membrane area is accounted for by the membrane area lost during the construction of an element - i.e., membrane covered by adhesives and other construction materials.

Construction techniques affect active area

RO elements that are manufactured in a precisely controlled and repeatable way generally have nominal and active membrane area values that are very close. If, however, the construction of an element is not precisely controlled, then the actual active area can be significantly different from the nominal membrane area claimed for a particular element - and can vary from element to element.

To achieve that precise control and repeatability, automated construction techniques may be used to produce elements with an active membrane area that most closely matches the nominal membrane area. For example, with the FilmTec Corporation's Automated Multi-leaf Element Cell (AMEC) technique, the difference between nominal and active area is typically two percent or less. Automated techniques allow for a level of accuracy and reproducibility that typically cannot be achieved by the manual or semi-automated techniques common to the construction of most RO elements.

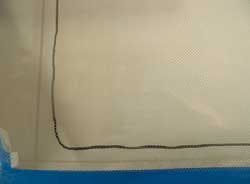

Figures 1 and 2 show the appearance of element leaves typically produced using the AMEC technique vs. conventional manual rolling technology.

Physical autopsies of a number of manually and automatically constructed elements have typically shown a greater spread of glue from the side of each leaf in manually constructed elements. Manual glue lines were usually about 5.1 cm wide but were observed to be as wide as 10.2 cm. Conversely, the automatically manufactured elements revealed glue lines that were only 1.7 cm to 2.5 cm wide.

Such widely variable glue line widths in manually constructed elements result in widely variable active membrane areas, even from element to element, making their nominal area values inaccurate. As a result of these differences in active vs. nominal area, it should be expected that many RO membrane systems in the field are actually operating at 15% to 20% higher average permeate fluxes than calculated from the nominal membrane area. This means that a system using products with inconsistent area specifications, designed for an APF of 14 L/m2h, would in reality operate at 16 L/m2h - a significant difference.

Measuring actual active area

One can conduct their own physical autopsy to determine whether an elements' actual active area is right for a system's optimal design and operation. Here's how:

Step 1: Remove outer wrap and end caps from element. First rinse the element to remove any biocides and/or other hazardous materials, then drain it in a vertical position for about 30 minutes to remove excess water. Next, use a vibration saw (such as model Astxe 638 or Msxe 636 from C. & E. Fein GmbH & Co, Stuttgart, Germany) and cut lengthwise to open the element's hard outer shell. Be sure to wear ample eye, ear and face protection as well as long-sleeved garments to avoid skin contamination with fibreglass particles.

Step 2: Unroll the membrane and count total number of leaves. A single leaf is defined as a rectangular sheet of tricot sandwiched between two layers of membrane and adhered around three edges by an adhesive.

Step 3: Select three leaves to make measurements. Leaves selected should be the most evenly spaced leaves in the element.

Photo by Dow

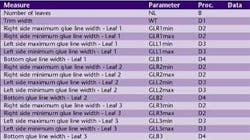

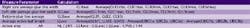

Step 4: Make and record measurements. Use the accompanying datasheets to record the following measurements:

• Measure and record trim width (trim width illustrated in Figure 3).

• Measure and record right side glue line width in two places - maximum value and minimum value (measurements must be made at places no less than 5 in. (12.7 cm) from permeate collection tube).

• Measure and record left side glue line width in two places - maximum value and minimum value (measurements must be made at places no less than 5 in. (12.7 cm) from permeate collection tube).

• Measure and record the distance from the end of the leaf to the inside edge of the bottom glue line on both sides of the leaf. Frequently this distance is different on each side of the leaf.

• Measure and record the width of the bottom glue line at the centre of three randomly spaced leafs.

• Measure and record total leaf length (continuous membrane length from end of one leaf to end of next leaf).

• Measure and record the width of any crease protection.

Step 5: Calculate active area. Use datasheets to calculate active and total membrane area.

As physical autopsies have shown, the differences between nominal and active areas may be significant and can lead to systematic inconsistencies when calculating the total active membrane area or the average permeate flux of an RO membrane system. One can physically measure the area themself to ensure that the system is optimised with the "Triple-A" — accurate active area.

Authors' Note

Markus Busch is the Sea Water Technology Platform Manager for Dow Chemical Company, based in Midland, Michigan, USA. Senior Technology Specialist Mark Huschke and Ian Lomax also work for The Dow Chemical Company.