Brazilian Water Utility Keeps Up with Fast-Growing Population Demands

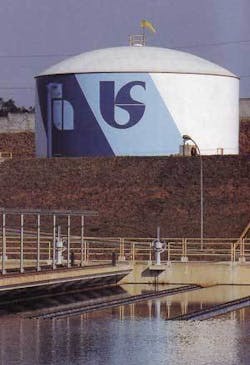

SABESP tests new GF Piping flow sensor at Presidente Prudente facility 400 miles west of São Paulo, Brazil.

Latin America is experiencing an unprecedented population boom, thus requiring increased investments in water and wastewater facilities to keep up with the growth. According to various independent studies, the total amount of facility investments will need to increase by a factor of three ? from a present day value of $18 billion to $60-$70 billion ? to satisfy the rapidly increasing water demand. Companhia de Saneamento Básico do Estado de São Paulo (SABESP), the São Paulo state water company, provides water and sewage services to a range of residential, commercial, industrial and governmental customers in the city of São Paulo, Brazil, and in 367 of the 645 other municipalities in the state of São Paulo, Brazil. The company also supplies water on a bulk basis to municipalities in the São Paulo Metropolitan Region that don’t operate water systems.

As a forward thinking company, SABESP is always looking for new and innovative ways to improve their processes. Teaming up with GF Piping Systems (USA), a supplier of pipe, valves, and flow monitoring instrumentation, SABESP tested its newly developed Signet 2552 Metal Magmeter flow sensor at the Presidente Prudente facility, which lies about 400 miles west of São Paulo. The new magmeter was released Feb. 1 and is expected to be widely used throughout Latin America, including Chile, Colombia and Mexico.

According to Hamilton Cassola, director of NIVETEC Instruments & Controls and a distributor of GF Piping products, “This facility, a municipal drinking water treatment plant, needed a reliable, low maintenance sensor installed in a 6-inch cast iron, cement-lined pipe on the effluent side of the plant”. The unit was to be installed through a ball valve and just downstream from a reliable full bore magmeter.

To meet these requirements, GF Piping offered the magmeter as a test unit. A six-inch 2552 magmeter with frequency output was installed and connected to a Signet 8550 Flow Transmitter.

“The test unit performed exceptionally well, closely matching the full bore sensor readings,” reported engineers in the Management and Operational Development Department of SABESP’s Presidente Prudente facility. “Because of its reliable readings, the Signet 2552 Metal Magmeter will be installed into our other facilities.”

The engineers also found that the magmeter required less maintenance and was easier to use compared to the rotors they had been using, which necessitated removing a hot-top paddlewheel when replacement of a pin or rotor was required. “At the present time, we use many rotor-type sensors that sometimes require rotor and pin replacements” explainsed the SABESP engineers. “With this new insertion magmeter, we expect maintenance-free performance and more consistent and reliable readings.”

Due to the need for a low maintenance flow sensor, NIVETEC also agreed to help GF Piping test the magmeter at other test sites. “These critical beta sensors tested in Latin America during 2006 taught us that the early prototypes needed improvement, so we went back to the drawing board to insure a robust sensor that could be used for hot-tapping into pressurized pipes up to 300 psi”, stated Sergio Guerrero, a GF Piping project engineer. “With the help of our valued customers, we now have a successful product that we are proud to offer to Brazil and the rest of the world”.

The 2552 is ideal for these type of harsh applications as it features no moving parts to wear or foul and high accuracy sensing without the excessive costs associated with full bore magnetic flow units. Without moving parts to wear, the unit accurately measures flow in fluids containing a high content of particles, solids and fibers, making it an excellent choice for applications with dirty fluids. Its design permits hot-tap access to the pipe stream, allowing quick and easy installation without system shutdown, significantly reducing overall costs. Outstanding performance characteristics include a wide dynamic flow range of 0.15 to 33 ft/s (0.05 to 10 m/s) with repeatability of ±0.5% of reading at 25°C, and linearity of ±1% reading.

In Brazil, SABESP is launching the first water-related public-private partnership (PPP) in the country. Its aim is to double the capacity of the Alto Tiete water treatment plant. Total value of the project is $170 million with five additional PPP’s soon to follow. SABESP invests approximately $500 million per year in capital investments.

“Because GF Piping has such an extensive line of Signet insertion flow sensors, they will be a strong partner with the expected expansions throughout all of Latin America,” said Hans Moesl, GF Piping general manager in Brazil.

Author’s Note:

Linda Meyers is a product manager at GF Piping Systems, which is based in Tustin, Califorinia, USA. GF Piping supplies a full range of plastic pipe, fittings, tubing, valves, actuators, rotameters, fusion machines, secondary containment, tank linings, heat exchangers, custom products, and sensors and instrumentation for industrial process control. Contact: +1 800-854-4090, Fax: 714-731-6923, [email protected] or www.gfpiping.com