Crustacean shells provide natural source for reducing stormwater contamination

By Everett Nichols, Ph. D. and D. Duane Dunk

For one road-builder in northern Idaho, USA, when it rained, it hurt - financially. The contractor and the Idaho Transportation Department (ITD) found themselves under the gun when an environmental agency fined them a hefty amount after storm runoff from a road-widening project contaminated a nearby creek.

The contractor found a solution that saved additional fines and helped keep the creek in near-pristine condition. The solution was from a source they least expected - crustaceans from the Pacific Ocean. For construction companies, efficient and effective stormwater management makes a significant difference between enduring delays and fines and finishing jobs on-time and on-budget. Historically, companies have used polyacrylamide and other synthetic, petroleum-based products to treat run-off from storms, land development and building activities; however these products are raising concerns about long-term environmental impact from potential degradation into toxic acrylamide monomer.

Strict regulations from government agencies and pressure from environmental interests fuel the search for solutions that are safe to discharge into natural waterways. The ITD discovered a solution derived from crab shells, Storm-Klear™ water clarifier, that treats stormwater naturally and bridges the gap between rigorous environmental policies and the builder's bottom line. Made from chitosan, a biopolymer refined from crab, shrimp and other crustacean shells, Storm-Klear reduces contamination in stormwater by lowering turbidity, phosphorous, metals, oils and grease. Biodegradable and non-toxic, it is safe for fish and plants, and there is no risk of degrading into toxic substances and harming the environment.

Chitosan forms long chains of molecules with cationic, or positive charges, which act like hooks to floc negatively charged organic materials and other contaminants suspended in water. Storm-Klear binds the particles in the first step, making traditional treatment methods - gravity settling tanks, biofiltration, sand filtration, cartridge filtration or pond re-circulation - more effective at removing contaminants.

One gel contactor unit treats 300,000 to 500,000 gallons of stormwater, depending on contactor configuration and flow rates, and both the liquid and gel forms of Storm-Klear work in flow rates ranging from 50 to more than 980 gallons per minute (gpm). The use-cost for chitosan-based gel clarifier is comparable to gel block polyacrylamides - and chitosan-based clarifiers handle a broad spectrum of soil types with a single formulation.

Industrial companies use chitosan-based Klarify-101™ to safely flocculate suspended contaminants from various food processing and other industrial process waste streams. Sludge settled from waste streams treated with Klarify can be recycled and used in fertilisers and animal feed.

In April 2002, the ITD was converting a two-lane road into a four-lane highway near Mica Creek - a sensitive stream that drains into Lake Coeur d'Alene, the jewel of the region's recreation areas. The project hit some roadblocks when the Department of Environmental Quality (DEQ) fined the ITD for releasing sediment-contaminated stormwater into Mica Creek, and a citizen action group sued the ITD seeking to protect water quality in Lake Coeur d'Alene.

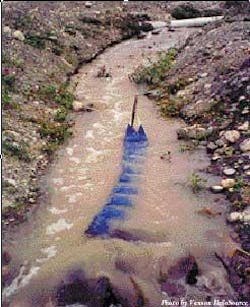

To comply with DEQ standards, the ITD needed a powerful water treatment system to process 650 gpm for the 100-acre project and reduce NTU from current levels - 1,200 to 3,500 NTU - to only 35 NTU. Using gravity settling enhanced by Storm-Klear Gel-Floc and sand filtration combined with Liqui-Floc, the ITD created a multiple-tank system that allowed ample flow rates and reduced turbidity levels to less than 5 NTU.

This innovative use of crab shell - in the form of Storm-Klear chitosan technology - by the ITD completely satisfied DEQ water quality standards and continued wet season work without costly delays.

Authors' note

Everett J. Nichols, Ph.D., M.S.P.H. is the vice president of research and development for Vanson HaloSource, the manufacturer of Storm-Klear, with facilities in Redmond and Raymond, Washington, USA. D. Duane Dunk is the vice president and general manager of the water treatment division at Vanson HaloSource.