Grundoburst replaces sewer line in Old Jeddah

ARABIAN JACKING ENTERPRISES FOR Contracting Trading (AJECT), a Saudi Arabian contractor, recently completed a difficult contract in "Old" Jeddah by using the TT Group's Grundoburst 1000G system. Its task was to provide a cost-effective trenchless solution for the replacement of 2.6 km of 150-mm-diameter cast iron sewer pipeline to be upgraded and upsized to 355-mm-OD polyethylene (PE) pipe over a period of 52 weeks. AJECT has since been awarded an additional contract for 2.5 kms in another area of Old Jeddah.

According to Trevor Cox, manager of AJECT's rehabilitation division, the project in Old Jeddah, located in the outer city area of Jeddah, required careful study to avoid numerous problems. Depths of the pipeline range from 5 m to 8.5 m; the water table averages only 2 m below ground level. The project called for replacement lines ranging from 40 m up to 120 m in length, operating from conventional excavations where possible but also from within manholes.

Trevor's experience of pipe-bursting led him to believe that a hydraulic form of static bursting would not be possible due to the high probability of ingress of sand and water into the equipment. Dynamic pneumatic impact pipe-bursting was also considered but caution was required due to the fact that no knowledge was available or records kept of the proximity of existing adjacent underground services and their fragile condition. Instead, AJECT decided to physically burst the existing under-capacity sewer line, expanding up the ground to the required diameter and pulling in new 355-mm PE short pipes.

AJECT purchased the patented QuickLock Rod hydraulic burst system from the TT Group. Roger Atherton and Arnold Bailey of the TT Group joined Trevor Cox in Jeddah to commission the equipment and provide operational training and after sales and service support for AJECT's own on-site personnel.

During early preparations, several problems were encountered associated with over-pumping, isolation work and narrow Jeddah streets. The major hazard, however, was controlling the ingress of groundwater in the drive and reception manholes. AJECT's team overcame this by fabricating a seal fitted on the face of the close shuttered sheet piles in the drive shaft and in the reception trench manhole. This seal, which had a thick rubber centre, allowed sufficient entry of the Grundoburst bursting head and the following two-stage expanders without risk of flooding or jeopardising the safety of personnel working in these 9-m-deep excavations.

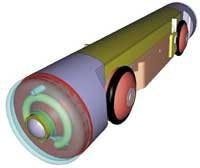

Due to the enormous one-step-up size of this sewer line, the tooling set-up was a special three-bladed (star) cutting blade and a 270-mm intermediate expander. A 420-mm final expander followed where the 355-mm PE (short) 0.6-m pipes were subsequently added as the burst progressed with the aid of TT's special pipe-tensioner device.

The total burst run took four hours including the lowering, positioning and attaching of each individual pipe length. The actual set-up of the Grundoburst equipment took half a day.

TT UK Ltd.

Bedford, UK

1 Preparations at the main working trench are complete and the Grundoburst 1--G (100T) hydraulic replacement rig is lowered in readiness for positioning.

Couplings and adaptors cater to water industry

SAINT GOBAIN PIPELINES LAUNCHED A NEW RANGE OF couplings and adaptors for specifiers and contractors in the water industry. PAM mLink and PAM uLink, complete ranges of couplings, cater to many applications and associated tolerances. PAM mLink is a flexible fitting with a high or "maxi" tolerance band covering pipe diameters from 50-mm to 300-mm and a maximum tolerance of more than 10% across all diameters.

PAM uLink is an "ultra" tolerance flexible fitting used when a joint is required between pipes or valves where the pipe diameter is not known and a large tolerance may be required. PAM uLink is available for pipe diameters of 50 mm to 300mm.

PAM mQuick is a range of flange adaptors that enable the specifier or contractor to connect pipework or valves to high tolerances, while the PAM uQuick solves problems arising from unknown pipe diameters and applications where larger tolerances are required.

Saint-Gobain Pipelines

Nancy, France

Sewer inspection system offers panoramic view

IBAK DEVELOPED THE PANORAMO TV system that includes a camera with a two-lens system that looks forwards and backwards. A computer processes both pictures taken in this way into a single picture. After the pictures are taken, the observer can choose the direction of view and decide whether to enlarge the view of a particular defect. Nothing is hidden from view using this system in sewer pipes. An advantage is that good inspection results do not depend on the professional skill of the operator. Experts can view at the stored sequences any time later. On-site inspections can be conducted more quickly since there is no need for detailed looking, shifting views and entering comments - all this can be done later in the office.

IBAK Helmut Hunger GmbH & Co KG

Kiel, Germany