Study evaluates membrane processes for surface water treatment

By Tosca Seidel, Kristin Jatzkowski

A comprehensive assessment of two membrane filtration processes and a conventional treatment process for surface water treatment conducted by the German company VA TECH WABAG determined ultrafiltration (UF) with immersed membranes to be the best technical solution for drinking water treatment of surface water in a solids-rich environment. Analysts concluded that conventional treatment was the most economically efficient process complying with the drinking water standards.

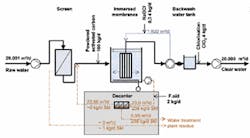

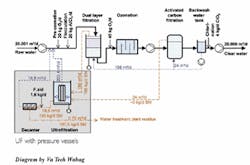

Interest in the application of membrane filtration of surface water is rising tremendously. For UF to be considered as an alternative to conventional clarification and filtration, VA TECH WABAG decided to compare three different processes not only by their ability to remove pathogens. The study compared value benefits, net present value and ecological costs to provide more comprehensive information for decision-making by municipal leaders, water companies and other parties involved in water treatment projects. The three processes studied included single stage UF with immersed membranes, UF with pressure vessels and conventional filtration process.

A pilot plant in Bannwil, Switzerland using surface water from the river Aare operated at different flow rates and with different additives to determine the flux conducted to measure process performance of the single-stage UF process with immersed membranes. River water quality often changes quickly, fluctuating wildly and varying by season. For example, the solid content of raw water and turbidity can surge within hours. Turbidity varies between 1.5 NTU to more than 100 NTU, while the average amounts to 4.5 NTU. Besides turbidity, the organic substances of content must be considered. The average TOC amounts to 2.6 mg/l while the average DOC was 2.1 mg/l; therefore the dosage of powdered activated carbon is used to eliminate AOX and DOC.

The first test series operated without any addition of powdered activated carbon and flocculants. The pilot plant could be run in a stable operating state during this time; however only the increase of the flux from 50 l/(m3h) to 63 l/(m3h) pushed the transmembrane pressure (TMP) over the operating limit. The addition of powdered activated carbon into the filtration tank showed that the immersed membrane maintained its filtration performance despite comparably high solid content. Conversely, the flocculant dosage did not significantly improve the filtration performance of the membrane, however it delayed fouling.

A water treatment plant with a capacity of 20,000 cubic metres per day and an availability of 80% was designed in a preliminary planning stage for the assessment and comparison study. The conventional filtration process starts with pre-ozonation, flocculation and particle separation by dual layer filtration. Ozonation eliminates bacteria and viruses, and then activated carbon filtration removes desolved adsorbable contents. Final chlorination keeps the drinking water sterile in the distribution network. In addition, all major material and energy flows were estimated.

The value benefit analysis used seven criteria: clear water quality, reliability of operation, maintenance, ground requirements, energy consumption, resistance to changes in raw water and waste disposal. This analysis showed that UF with immersed membranes produced high quality water, required the smallest space for the whole process, and consumed a very small amount of chemicals and additives. The analysis ranked UF with pressure vessels as second, and the conventional system as third.

Keeping in mind that the assessment is only valid within the study boundaries and assumptions, it should be noted that none of the investigated processes can be considered as advantageous in all technical, economical and ecological points, however transparent and concluded information is provided for decision-making.

Author's Note

Tosca Seidel, Kristin Jatzkowski work for VA TECH WABAG in Butzbach, Germany. For more information, contact the author at Email: [email protected]