Turbines recover 90% energy in seawater reverse osmosis plants

By: Beat Schneider

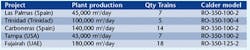

Energy recovery turbines (ERTs) manufactured by the Swiss company Calder AG have been delivered to some of the largest seawater reverse osmosis desalination plants in the world, including Las Palmas, Spain; Trinidad; Carboneras, Spain; Tampa, USA; and Fujairah, United Arab Emirates, within the past five years. The ERTs in these facilities recover approximately 90% of the brine reject energy, which result in significant savings in energy costs.

Calder's smallest turbine model is rated at 20 kW, while its largest model is rated at 1,800 kW. In large-size plants, the ERTs are always designed for a specific duty point or range. For example, the turbine in Trinidad, the largest train in the world (20,000 m3 per day), is designed for 880 m3/h with a pressure range of 39 barg to 72.4 barg. The speed range is from 2,700 rpm to 2,235 rpm. Close cooperation between the contractor, pump manufacturer and Calder helped achieve the best possible efficiencies of the relevant components over the full performance range of less than 2.5 kWh/m3 of product water.

Energy recovery in SWRO was not widely used twenty years ago, and where turbines were installed, they were based on reverse running pumps. Francis turbines were the preferred option as energy recovery machines. Calder AG first evaluated the concept of an energy recovery turbine based on the Pelton wheel technology 20 years ago. The first prototype machines were based on standard hydro-electric impulse turbine hydraulics, but with significant differences in material selection and mechanical build specification.

The Calder ERT accounts for approximately 90% of the energy recovery devices fitted to larger, in excess of 4000 m3/day SWRO plants. Its hydrodynamic characteristic allows for a wide range of variable parameters without a significant reduction in design efficiency. This means that flow and pressure variations in the RO desalination process (from starting phase up to a long-term running operation), does not affect to any significant degree the running conditions and efficiency of the turbine.

The impulse turbine operates over the whole range of operating conditions. Within a specified operating range cavitation does not occur, ensuring a long lifetime of the rotor system, typically in excess of 10 years. Another advantage is that mechanically, the rotor is the only rotating element in the system. Fewer components in the turbine lowers capital cost of the equipment.

Another very important factor is the reliability of the Calder energy recovery turbine. Over 1,000 units are now in operation worldwide and reliability in excess of 99% has been proven. In many areas where our products are in operation the local people rely on fresh water from the desalination plant. A loss in production would immediately cause serious problems. Further to that larger projects are often on a build-own-operate or build-own-transfer basis; therefore production affects income while downtimes might even lead to penalty claims.

The most exposed and stressed materials in the main turbine parts are made of Super Duplex stainless steel, so they are free from galvanic corrosion. The hydrodynamic system elements, such as inlet-nozzles, needles and wheels are cast and machined in materials of high-grade resistance to jet impact, high-speed fluid friction erosion and cavitation.

Author's note

Beat Schneider is the general manager of Calder AG, based in Egliswil, Switzerland. For more information, visit the website: www.calder.ch or contact by email: [email protected].