Heineken Brews Better

Biogas Production with Added Nutrients

Added micronutrient technology helped a brewery in Spain to save costs, enhance biogas production and stablise digestors after the facility had problems with treatment. A look at results from applying a solution containing complex compounds of iron and manganese, among others.

At Heineken Spain's brewery in Seville wastewater generated is treated in the two Waterleau designed UASB (Upflow Anaerobic Sludge Blanket) reactors. Unfortunately the plant start-up did not run smoothly and the anaerobic digesters did not perform as well as expected - the inoculated sludge developed an unusual appearance and didn't grow.

Microorganisms involved in the anaerobic digestion of wastewater have particular nutritional requirements. In most wastewaters there is usually more than enough of certain food components and a deficiency of others.

In the case of breweries, there is usually an excess of carbon, hydrogen, oxygen (carbonaceous compounds), sulphur and the macronutrients (nitrogen and phosphorus). The latter two may have to be removed by a separate process. There is often a shortage of others such as minerals and essential trace elements (micronutrients).

Micronutrient mix

The essential trace elements are those elements required as cations in minute quantities but indispensable to the proper function of the microorganisms. Sometimes these elements are not present in the wastewater or they are in a form that is not available to the microorganisms. Hence trace element addition is a usual practice for industrial anaerobic effluent treatment in Europe. A laboratory analysis of the Heineken brewery's wastewater revealed some indications of a shortage of micronutrients, which could be related to the process deficiencies encountered. It was proposed that plant performance could be improved by using a nine micronutrients mix.

Looking for a solution to this problem, Heineken turned to Omex Environmental (OE), which provides concentrated bio-available solutions of micronutrients called Nutromex® Trace Elements Additives (TEA). It was decided to do a five month trial in UASB 2 with Nutromex TEA 310, a solution containing complexed compounds of iron, manganese, nickel, zinc, cobalt, molybdenum, copper, boron and selenium.

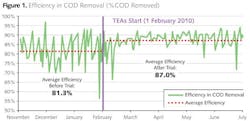

The anaerobic digester treats about 3000 m3/day of wastewater at a chemical oxygen demand (COD) concentration of 3200 mg/L. Following the addition of Nutromex TEA 310 in February 2010, the digester performance started to improve within one month´s use. Daily figures of several performance parameters were recorded and studied three months prior to the use of TEAs and five months afterwards.

Before dosing TEAs, the COD removal efficiency varied from 70% (even as low as 55%) to 95% whereas when using TEAs the efficiency was much more stable. In addition to this, the average COD removal efficiency increased from 81.3 % to 87%, although the COD load was about 8% higher from February onwards.

More COD removed in the digester leads to more biogas production, which actually increased by 27% on average. Apart from that, sludge activity improved with the dosing of TEAs, as the specific biogas production (amount of biogas produced per kg. of COD removed) rose by 13%. This means that the greater volume of biogas produced was due to the improved COD conversion into biogas, but there was also a higher COD load at the same time.

The amount of volatile fatty acids (VFAs) produced by the digester decreased in the TEAs trial, which could be directly related to the increased biogas production and the improved sludge activity. VFAs out of the reactor were rather unstable prior to the TEAs addition.

Cost savings

VFA concentrations could easily vary from 10 mg/L to 350 mg/l - a rather high concentration. However, after approximately one month, VFAs levels started stabilise around a concentration of 35 mg/L. The average VFA out concentration dropped about 88% - from 91.5 mg/L (before TEAs) to 48.6 mg/L. With greater methanogenesis, biogas production improved allowing a greater saving in the costs of running the brewery boilers.

The new nutrient solution also heralded an improvement in suspended solid removal, which decreased by around 16% while the sludge grew considerably - in the five months of the trial it increased from about 16,000 kg to 23,000kg.

Clearly, in general, the majority of the plant's performance parameters were positively influenced by the micronutrient mix addition while the major benefits associated with the change have helped improved digester stability and increased biogas production, yielding significant savings for Heineken Seville.