Field trials demonstrate higher efficiency of UV reactor

G. Bord, P. Girodet, P. Marlin

Anjou Recherche tested the OTV technology UV-Star® to assess its efficiency compared to other current ultraviolet disinfection reactors for wastewater.

A team of researchers at Anjou Recherche concluded from field trials that the electrical and mechanical design of UV-Star®, the ultraviolet disinfection technology developed by OTV of Veolia Water Systems, achieves a higher removal efficiency than current technology.

Pilot trials of UV-Star and two alternative UV reactors were conducted at the wastewater treatment works of Mantes-la-Jolie, France, as the next development stage of this innovative low pressure, open channel UV reactor. This wastewater treatment plant is a conventional medium-load activated sludge facility.

Each unit was designed according to the same parameters for a representative study. The purpose of these trials was to assess the performance of each plant and compare their relative efficiency. To achieve a representative analysis, the electrical consumption versus the logarithmic removal efficiency was considered instead of the UV dose applied into the reactor. The research team decided that this approach would eliminate potential discussions regarding the definition of a UV dose, which can be subject to misinterpretation.

Extensive results of the trial demonstrated the benefits of both the electrical, mechanical and hydraulic design of UV-Star. The research team concluded that the UV-Star operated at a logarithmic removal efficiency rate of 30 percent higher for identical electrical power consumption in comparison with current technology.

The Mantes-la-Jolie plant is a 125,000 Population Equivalent (pe) conventional medium load activated sludge plant. One specific trial took place during 11 days when the three UV reactors received an identical final effluent. The characteristics of the feed to the UV plants are given in Table 1.

No iron-based coagulant was dosed on the treatment works during the trial, which would have affected UV transmissivity. The tests were conducted after allowing sufficient warming up time for the lamps to reach stable and efficient operating conditions. The trials started with all new lamps and quartz sleeves on all pilot plants. Maintenance and cleaning were carried out equally on all units ensuring no fouling occurred more on one system than the other.

All systems incorporated a single bank of lamps and use low-pressure UV lamps. The UV-Star pilot plant tested incorporates one bank installed in a stainless steel channel. A total of 18 low-pressure lamps rated at 400 watts provide the germicidal yield with an overall efficiency from 30 percent to 40 percent at the wavelength of 254nm. The flow was treated continuously during the pilot trial, 24 hours per day. This test provided an opportunity to assess the combined effect of the technical innovations incorporated in the unit, namely:

• Latest low-pressure lamp technology. Technology has improved to increase the power and lifetime of the lamps. UV-Star low-pressure lamps are characterized by a maximum rated power of 400 watts.

• Electrical. A sophisticated transformer system drastically reduces the cabling length and cost by having only two wires per lamp instead of eight. Real-time monitoring of each lamp’s status provides effective operating conditions and allows up-to-date maintenance.

• Mechanical. A single, automated cleaning system with tailored wiping rings and supports requires simple maintenance because of the low number of parts. Individual lamps are protected from jamming by an elastic coupling released under excessive mechanical stress.

• Hydraulic. A hydraulic shortcut of only 1 percent of the incoming flow could reduce the overall disinfection efficiency from 3.0 to 2.0 Log Units removal. UV-Star maintains optimal disinfection by proposing an innovative off-set lamp design preventing hydraulic short circuit while reducing headloss.

Results

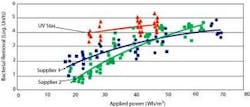

Graph 1.0 indicates the results expressed as log C removal efficiency versus electrical consumption. Comparing the performances of UV-Star with the two other products UV-Star demonstrates a significantly improved efficiency. As the same influent has been treated in parallel on the three streams, it is relevant to compare the applied electrical power. It appears that for a UV transmission in excess of 50 percent and with an electrical consumption of 25 Wh.m-3 (equal to a UV dose of 400J.m-2) UV-Star provides an efficiency removal of 3.0 Log Units whereas the two other reactors achieve 2.0 Log Units removal.

Conclusion

The OTV process technology has been tested in identical operating conditions alongside two other highly reputable products currently available on the market. UV-Star provides a higher bacteriological removal on Total and Faecal Coliforms for the same absorbed power. The cutting edge mechanical and electrical designs of the unit have demonstrated its overall efficiency and confirmed the advantages of this system.

Authors’ Note

Development Engineer Genevieve Bord, Department Head Pierre Girodet, and UV-Star Product Manager Pascal Marlin (OTV-UK) are part of OTV/Veolia Water, which instructed the study carried out by the subsidiary Anjou Recherche. The center is located in Maisons-Laffitte, outside of Paris, France.