Cooling water treatment system free of chemicals

Hydrodynamic cavitation technology (VRTX) conserves water and requires no hazardous chemicals in a cooling water treatment system operating at a government building in Madrid, Spain.

A hydrodynamic cavitation technology (HDC) is conserving water and eliminating the use of hazardous chemicals in the cooling water system of a government building in Madrid, Spain. In May 2005, the US company HydroVRTX installed the system, consisting of a VRTX and separator/bag filter, to control scale, eradicate bacteria, and control corrosion in the building’s cooling towers. After six months in operation, water remains clear and the heat-exchanging surface of the VRTX is clean. Prior to installation, approximately i5,500 were spent on water treatment chemicals.

HDC technology is an established technology that has proven to be effective in controlling scale, corrosion and bacteria (including Legionella) in industrial cooling water systems while lowering operating costs and saving water. The HDC system provides long-term, predictable control without chemicals, constant adjustment and costly blow-downs.

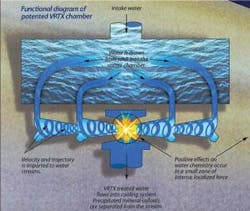

HDC is a mechanical device and operates as a side-stream treatment system. The system includes a HDC unit and a separation/ filtration unit. The HDC unit works primarily on the principles of kinetic energy, chemical equilibrium and controlled hydrodynamic cavitation.

The VRTX chamber creates tremendous force that causes molecules to collide in the hyper kinetic zone. This intense zone of energy causes high temperatures and pressures with sufficient energy to affect the equilibrium of chemical equations of molecules. Microorganisms are typically incapable of surviving and mineral bonds in water are broken as they pass through the system.

The HDC actions destroy microbial cells and converts dissolved calcium carbonate collide, which are then filtered from the treated water. Bacteria is eradicated by a combination of synergistic actions pressure, vacuum, kinetic impact and shear force at the collection point, hydrodynamic cavitation, sonic waves and oxidizing chemicals produced from HDC.

Using this technology makes it possible to reduce water consumption, to reduce discharge and to eliminate environmental pollution from the use of hazardous chemicals. A HDC system will reduce water consumption by operating at higher cycles of concentration (COC) and reduce discharge. A typical installation on a 1,000-ton system can save 60 percent to 80 percent in blow down.

A HDC system can also effectively control scale, corrosion, and bacteria without chemicals; lower energy costs five to ten percent by avoiding scale build-up and keeping the system clean. Returns on investment typically range between 12 to 48 months. The technology is environmentally safe with no health risks.

HDC technology is being used in various process streams such as white water, clear water and brown water in the pulp and paper industry when the use of biocides can be significantly reduced.

The technology’s water saving benefits are substantial. For example, an industrial manufacturing company that uses a HDC system to treat its condensers can save more than 12,000,000 gallons of potable water per year, then keep it from being wasted in sewer systems and finally save municipalities from treating it in sewer treatment plants. As businesses expand and communities develop, water resources are strained to keep up with demand. VRTX can help to conserve water for other uses.

An average four-person household in the USA uses 146,000 gallons yearly. At these rates, water saved can supply 82 households per year.

HydroVRTX BV, located in the Netherlands, is a master distributor in Europe of VRTX Technologies in the USA 15 years ago, but began expanding into Europe only recently. In Europe, the longest running VRTX application began in 2003 in the Netherlands at a dairy plant to control microbiology in cooling water. Heat exchangers increased their heat transfer capacity by reducing microbiology. The VRTX is installed to eliminate chemicals and reduce water usage. HydroVRTX also has distributors of VRTX technology in Finland, Sweden and Germany.

Author’s Note

Herbert Eppinga is the sales manager and technical support for HydroVRTX, located in Almere, The Netherlands. For more information, visit www.hydroxs.com or email: [email protected].