Rethinking Wastewater Treatment

While most sludge treatment technology used today is the same as invented back in Victorian England, drivers and issues are very different. Energy and resource recovery were not a major concern in the early 1900s as they are today. Taking a nostalgic look back at the development of wastewater treatment, this article asks whether there needs to be a fundamental change.

By Dr Bill Barber

A great deal has changed both globally and in the world of wastewater treatment since Karl Imhoff patented his sludge treatment invention in 1909 in Germany. The benefits of storing sewage in a tank to reduce its putridity and quantity had been noted in the years preceding Imhoff's invention, although the concepts for the need of sewage treatment date back further to a report by Sir E. Chadwick on the Health of the Working Classes published in 1842.

However, it was a severe cholera epidemic which incentivised the UK Parliament to pass the Nuisance Removal Act in 1855. This began the scientific study of the chemistry and biology of sewage sludge. The first forms of sludge treatment were straightforward collection and diversion to the nearest water-course rather than allowing it to accumulate near dwellings.

It wasn't until 1857 that it was a legal requirement to remove suspended matter or "deodorise" sewage prior to its "admission to the streams". In the mid-19th century the UK was undergoing unprecedented technological development, and the waste materials from the industries which fuelled this development also found their way into the water eco-system.

According to textbooks written at the time, sewage sludge would contain wastes from tanneries, wool mills, dye works and paper works, as well as coal ashes, slag, solid refuse from earthenware manufacturers and metal works, soil, stones, clay from quarries and mines, road grit and filth from the streets, and last but not least a variety of animal carcasses.

When sewage sludge was passed into comparatively small rivers from high population density areas, it caused severe pollution. So much so, that the varied industries of the Victorian era blamed the sewage for contaminating their water supply. Not surprisingly, the original drivers for sewage treatment were to reduce river pollution as well as human health. An Act of 1861 was passed which required that sewage should be purified and freed from faecal and other putrescible matters prior to stream and river discharge.

Until 1893, the disinfection of sewage was regarded as a comparatively simple and inexpensive problem. It was thought that the addition of lime, until the sewage became slightly alkaline, was sufficient to kill any typhoid or cholera bacilli which might be present.

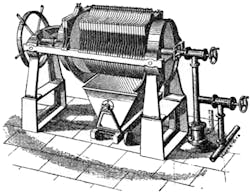

However, varied and inconsistent results led to development of further technologies, principal of which was the septic tank (precursor of Imhoff's invention of 1909), and itself a further development of Mouras' Automatic Scavenger. This was because it was discovered that storage of septic sludge under anaerobic conditions reduced both the numbers of disease causing organisms and the sludge itself.

Writing in the British Medical Journal in 1898, Scott-Moncrieff - a prominent figure in the Water Industry during the late 19th and early 20th centuries - lamented the passing of Louis Pasteur. Scott-Moncrieff was certain that the germ theorist would have been encouraged about the future of sewage disposal by means of "putrefactive fermentation, followed by nitrification of the organic matters under highly aerobic conditions".

During this time, a great deal of innovation was occurring with the development and understanding of anaerobic digestion. Among several inventions and patents, one (US 663,623) was granted for a device to hold sewage or decaying organic matter in enclosed covered tanks such that "gases will be generated which may be beneficially and economically employed for the purpose of illumination or heating or for obtaining motive power in explosive-motors".

To put that in context, an article in Science from 1904 enthused about a breakthrough in technology development "perhaps as great as when Stevenson first drove a locomotive along a railroad" whereby, at the tail end of the previous year a contraption weighing 700 pounds powered by a 16 horsepower engine flew a distance of three miles over the skies of North Carolina. The aircraft in question, the Wright Flyer, took to the sky three years after the patent for the anaerobic digester was granted.

The technical innovation of the time was itself complemented by increasing understanding into the theory of anaerobic digestion. Equation 1, based on the understanding of the time (reviewed by Rideal, 1906) shows the fermentation of sewage in a septic tank.

Prior to anaerobic digestion which became established in the mid-1890s, wastewater treatment was almost exclusively founded on chemical addition with early sludge engineers akin to medical apothecaries. Some of the more exotic materials added to treat sludge included: sawdust moistened with sulphuric acid (to aid dewatering), turpentine, alcohol, iron filings, brick dust, oil tar, hydrochloric acid gas, tanners's spent bark, animal charcoal, salt, sugar, urine, carbolic acid, phosphoric acid, "soft-sludge" from alum works, numerous metallic salts, blood and so forth.

One patent that catches the eye though is No. 3,566 filed in 1867 by A. M. Clark which "treats sewage with neutral phosphate of magnesia, in order to precipitate ammoniaco-magnesian phosphate". In modern language, this is the intentional production of struvite from sewage sludge, a practice which is gaining ground at full-scale in the 21st century.

Learning from the past

Interestingly, studying old texts and archives reveals that much of what we see today on a wastewater treatment works is from the 19th century. Technology and concepts from that epoch includes: screening; primary treatment; anaerobic digestion; exploitation of biogas (initially for street illumination); dewatering; use of biosolids for nutritional value; thermal drying; nutrient extraction and recovery; application of activated carbon for odor abatement.

4 C8H13N2O3 + 14 H2O = 4 N2 + 19 CH4 + 13 CO2 + 2 H2 (Equasion 1)

In fact, the only major process operation which is not of that period is that of activated sludge which made its breakthrough in 1914 in Manchester. Here it was found that maintaining the sludge, rather than discarding it as was done previously could significantly reduce nitrification times to acceptable levels. Even so, the importance of nitrification for wastewater treatment was discussed in the UK in the 1880s.

However, the issue with having wastewater treatment plants designed to meet 19th century drivers based on concepts of that time is that we live in a fundamentally changed world needing to meet different drivers and issues. In Victorian England, public and waterway health was paramount; little concern was given to water conservation, energy or resource recovery.

The importance of water conservation, energy and resource recovery is becoming increasingly apparent. There is no more fresh water today than there was 2000 years ago when the population was 2% of what it is currently. Yet, in twenty years' time, there will be over a billion additional people inhabiting the planet, and in Asia, over half the population will be living in mega-cities.

This increased population will also be wealthier and consume more and varied materials. In China, eating habits are already evolving to a more meat, rather than vegetable centered diet. Meat based diets need approximately three times the nutrients and consume many times the water and energy needs of their meat-free alternatives for them to be sustained.

Energy recovery

Wastewater treatment plants are fundamentally intertwined with water, energy and resources, and therefore play an important role on a global scale. Regarding water, on the whole, wastewater enters a plant, is processed, and like the 19th century engineers did before us, is then discarded to the local waterways.

In times of increasing water scarcity and drought accelerated by climate change, there may be instances when this water could be used, for example as irrigation water, also practiced in the 19th century with the water decanted from primary settlement of sewage.

Perversely, in some instances the water exiting a treatment works is cleaner than the waterways it is being transferred to, with detrimental impacts on the local environment. As far as energy recovery is concerned, best practice involves installing anaerobic digestion technology based on the aforementioned patent from 1900. This is combined with a pre-treatment add-on on to ensure approximately 60% of the inherent energy within the sewage is captured. This energy is then processed through combined heat and power plants where a further 60 -- 70% is lost as heat, resulting in a recovery of only 10 to 20% of the energy available.

As mentioned previously, anaerobic digestion was not conceived for energy recovery or reduction of anthropogenic carbon footprint, but rather the partial inactivation of 19th century disease causing organisms relevant to the time -- the biogas produced was therefore a by-product.

Also, faced with a culture of law suits surrounding patent infringements especially in the US, early 20th century designers became inherently conservative. Subsequently these conservative designs became textbook standards, most of which are still widely used and hamper further innovation. Coupled with poor energy recovery, wastewater treatment plants are chained to activated sludge processes which crave energy. Some nutrients are recovered within the biosolids produced from wastewater treatment when it is beneficially used as a fertiliser. However, more are systematically destroyed using activated sludge treatments and their modern variants, which convert the nitrogen in the wastewater back to its gaseous form.

These processes can account for between half and three quarters of the entire energy demand of a wastewater treatment plant. Ironically, at the same time the activated sludge process was established, the first full-scale Haber Bosch plant was commissioned to make 20 tones/year of ammonia fertiliser. That process works by fixing gaseous nitrogen from the air and combining it with hydrogen extracted from methane at high temperatures and pressures (500°C and 200 -- 250 bar). Not surprisingly, it is a heavy energy consumer and accounts for approximately 5% of the globe's gas and up to 2% of the energy consumption.

Regarding the conservation of water, energy and resources, our wastewater plants clearly have room for improvement as they were not intended to achieve those goals. As these parameters increase in importance moving forward, it is clear that the treatment plants of tomorrow will need to evolve and adapt to help meet these needs in a manner which is both environmentally and, importantly, financially sustainable.

Dr Bill Barber is technical director within AECOM's water business line. He will be giving a keynote presentation on the Future of sludge treatment at Aqua Enviro's 20th European Biosolids & Organic Resources Conference and Exhibition at Manchester Town Hall, UK 10th-11th November 2015.

More Water & WasteWater International Archives Issue Articles