The Big Question: Ultraviolet Treatment (UV)

What recent innovations have made UV disinfection technology for water treatment more competitive?

In WWi's ongoing technology series we ask a question to manufacturers of key water/wastewater procesing technology. Next up is ultraviolet (UV) treatment technology.

Uniform Dose DistributionWayne Lem, Municipal Market Manager, Trojan Technologies

Ultraviolet (UV) light technology is commonly used in North America for municipal water treatment. Today, UV is a preferred approach to wastewater disinfection and continues to grow in drinking water disinfection applications as well. In addition, point of use treatment of residential tap water as well as industrial water including food and beverage preparation have benefited from UV-based disinfection.

By avoiding the use of chemicals, UV provides the highest degree of operator and environmental safety. Furthermore, UV forms no disinfection by-products.

While UV does use on site electricity where chemical disinfectants do not, with chlorine-based disinfection other operating costs come into play such as the transport/delivery of chemicals, implementation of risk-management plans and replacement of parts which are in a highly corrosive/oxidising environment. Ongoing reductions in power consumption and costs are enabling UV to become an even more competitive disinfection technology choice. Improvement in the overall efficiency of UV disinfection systems is a significant trend in the industry.

Manufacturers are also adopting approaches to increase efficiency, including the development of more efficient lamps. As UV lamps increase in electrical efficiency, they continue to accomplish the same level of disinfection with lower electrical energy demand and fewer lamps. By producing the highest output, highest efficiency low-pressure UV lamps, this means lower lamp count and reduced maintenance.

In addition to enhanced lamp performance, UV systems need to be engineered to ensure optimum hydraulics and maximum use of the UV energy generated by UV lamps.

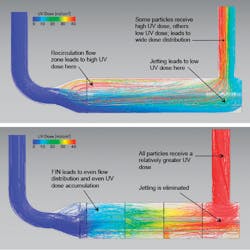

Specifically, new flow modification techniques tailor the flow through a UV chamber so that areas of high flow velocity receive high levels of UV intensity and conversely, areas of low flow velocity receive low levels of UV intensity. The final result is a uniform dose distribution throughout the UV chamber (see figure). A more uniform dose distribution results in reduced equipment requirements, less energy, and an improved value proposition for UV in general.

Reducing overall maintenance and operating costs associated with UV systems ensure that the technology will continue to grow in both competitiveness and popularity.

Even Flow DistributionKirsten Meyer, UV Product and Application Manager, Xylem

Two major factors have driven competitiveness. First is a significant improvement in lamp and ballast technology towards higher powered, energy efficient and longer lasting amalgam UV lamps.

Second is a better understanding of pathogen specific UV sensitivity and the influence of different wavelengths, have had a significant impact on appropriate system sizing.

Higher powered amalgam lamps significantly reduce the total lamp count and the space required. Advancements in the design of electronic ballasts in combination with intelligent UV system control have optimised dimming capabilities while also reducing power consumption.

Computational fluid dynamics and system validation have combined to optimise system design making today's reactors more efficient and easier to maintain. Even flow distribution and new lamp arrangements are just two examples of recent design improvements.

An understanding of how different pathogens respond to UV light has significantly changed the sizing of UV systems. This was first established following the publication of the UV Disinfection Guidance Manual (UVDGM) by the US Environmental Protection Agency (EPA) in 2006, where different dose levels were determined together with log inactivation credits by surrogate.

These developments led to conclusions such as the fact that cryptosporidium, an organism which can be difficult to destroy with chlorine, is effectively inactivated by a small UV dose.

Applying this concept to wastewater disinfection, known as the DL approach, allows for a 'best fit' design to the site specific pathogen. Hence, overly conservative design parameters are unnecessary to ensure the disinfection objective is met thus reducing overall UV system size.

Removing Personal Care ProductsSimon Evans, Research Analyst at ATG UV

UV disinfection continues to prove its worth in wastewater treatment as an alternative to chemical disinfection.

The misconception that UV as a technology was considerably more expensive than alternatives has been mitigated over the past few years. Now innovations have established UV as a cost-competitive option for the industry.

Advancements in lamp technology have led to longer lamp life and consequently fewer lamps are required. UV systems are increasingly becoming more energy-efficient as lamp innovation and variable power supplies allow for reduced power usage.

These innovations have led to a life-cycle cost reduction of the UV system allowing for OPEX savings.

As regulations on Priority Substances continue to become more stringent and new substances identified in the Water Framework Directive, innovation in new technology is vital.

UV is at the forefront of tackling this problem as an integral part of Advanced Oxidation Processes (AOP) that can break down contaminants in the water which are difficult to remove. Recently, such difficult to remove contaminants, specifically pharmaceutical and personal care product (PPCP's) and pesticide residuals, have been affecting water quality.

It appears that UV AOP is the most promising cost-effective solution to this growing problem as testing continues. UV is best equipped to meet stringent regulation now and in the future as new challenges face the industry.

More Water & WasteWater International Archives Issue Articles