Product Review: Sensors, Monitors & Meters

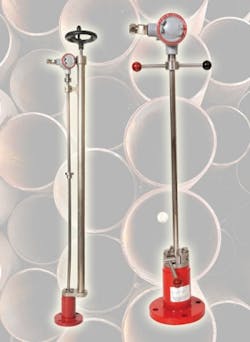

Turbine flowmeter for large pipe metering

A range of turbine flowmeters has been launched that are suitable for large pipelines where the cost of inline meters can be prohibitive, said Filton Process Control.

The Series 5000 flowmeters can be installed and removed through a suitable valve while the flow line continues to remain under pressure. According to the manufacturer, the principle of operation is as fluid flows through the turbine assembly it causes the blades of a freely supported rotor to turn at a speed directly proportional to the flow velocity.

A pick–up assembly fitted into the insertion stem immediately above the rotor detects the passage of each blade tip and generates a sine wave output, the frequency of which is proportional to the turbine rotor speed and hence velocity and thereby flow rate. This signal may then be used in conjunction with local or remote signal conditioning electronics a comprehensive range of which is also available.

The flowmeters can be fitted with different, interchangeable rotor assemblies and are available with a wide range of electronic signal conditioning and readout instruments. Readout equipment can be locally mounted, or remotely when a preamplifier is used, and distances up to 3000 metres can be accommodated. When used in conjunction with a ball valve, the metering head retracts fully into the housing so they can be removed without interrupting fluid flow.

Series 5000 flowmeters are ideal for pipeline diameters from 4" upwards and meet most installation requirements for oil, gas and general industrial flow metering operations.

http://filton.com/products

Level sensor for tough environments

Endress+Hauser has launched the Waterpilot FMX21 level sensor for wastewater processing which it said can make level measurements in "nasty environments" such as sludge, wastewater and salt water.

The Waterpilot FMX21 level sensor has a stainless steel housing and an easy–to–clean, flush–mounted process diaphragm and with an optional Pt 100 sensor, it can also measure temperature. A corrosion–resistant, coated version is available for use in particularly aggressive environments, such as salt water.

The FMX21 uses a ceramic cell to measure pressure. Any changes in pressure cause a change in capacitance, which the sensor's electronics convert into a 4–20mA signal that is linear to the level of the liquid. HART 6.0 is superimposed on the 4–20mA signal, allowing an operator to adjust the range remotely.

The sensor is said to be ideal for sludge because the ceramic cell withstands corrosion better than any other material. Endress+Hauser said a characteristic of ceramic diaphragms means that cleaning is very easy, without losing calibration. Applications include lift stations, thickeners, digesters and sludge holding tanks.

For water and wastewater applications, it has KTW, NSW and ACS drinking water approvals. By using the Field Xpert PDA, operators can communicate to the FMX21 wirelessly, to set all parameters and diagnose problems.

www.us.endress.com

Battery powered electromagnetic meter offers location flexibility

A battery powered electromagnetic flowmeter has been launched by Arkon which it said makes it possible to install a "reliable flowmeter virtually anywhere, without sacrificing accuracy or performance if mains power is not available".

The model is powered by 2 x 3.6V lithium batteries placed inside the transmitter and battery life is said to be up to five years. Communication is done via USB using MODBUS RTU protocol. Compact and remote versions are available (cable length limited to six meters for remote version).

Features of the MAG B1 include: Accuracy: ± 0.5% of actual value; graphic display and keypad for simple operation and instant access to information of 4 totalizers: total +, total –, total, aux; graphic display turns off automatically when it is not being used, for battery conservation; error detection; empty pipe detection, automatically turns off the excitation to prolong battery life; two built–in earthing electrodes; standard USB interface communication via MODBUS RTU for configuration and data collection using MAGB1 software; isolated binary output (pulse per liters or alarm or flowrate functions); data logger – 1820 records, selectable interval of logging (5min – 24h); adjustable filter constants 1 – 30 samples and all units include a calibration certificate issued by an independent calibration rig and traceable to international standards.

www.arkon.co.uk

Onboard in–situ flowmeter verification capability

ABB said the integration of an easily accessible and in–situ flowmeter verification capability is helping to develop precision flow measurement.

Built into the WaterMaster flowmeter, the VeriMaster system provides users with the ability to perform in–situ verification across the complete range. Verification diagnostics monitor and validate across a performance–wide matrix, while precision flow measurement techniques are employed in the sensor with an octagonal bore at core sizes.

By using the simultaneous and parallel operation of the HART protocol, remote HMI and cyclic data output are said to all be achieved with zero measurement loss during data capture. The addition of the VeriMaster software tool enables operators to quickly produce a printed verification certificate for regulatory compliance.

'Fit and Flow' data storage inside WaterMaster eliminates the need to match sensor and transmitter in the field. On initial installation, the self–configuration sequence automatically replicates into the transmitter all calibration factors, meter size and serial numbers as well as customer site–specific settings. The meter is verified to OIML R49 type 'P' requirements to ensure the highest accuracy and long term performance of the system by continuous self checking the sensor and transmitter in the field.

WaterMaster gained one of ABB's first MCERTS flow product approval certificates in November 2008 and has been adopted by several EPR operators and water companies for EA Consented applications. The introduction of the VeriMaster Software Tool strengthens the ability of users to be able to electronically verify flow meters and actively demonstrate a good metering maintenance regime. Tony Hoyle, UK flow products manager, said: "With the addition of VeriMaster, the bar has been raised to the next level for all water, waste water and effluent applications."

www.abb.co.uk

More Water & WasteWater International Current Issue Articles

More Water & WasteWater International Archives Issue Articles