Comparison of 8–inch and 16–inch Modules at Bedok NEWater Factory

The Dow Chemical Company is conducting a side–by–side evaluation of DOW FILMTEC™ 8–inch and 16–inch modules at the Bedok NEWater Factory (NWF). The pilot plant was commissioned on October 8, 2007, and recently passed a milestone marking 30 months of continuous operation. The pilot plant is run at flux rate of 18 to 22 L/m2–h and recovery of 75%, conditions comparable to the NEWater 8–inch reverse osmosis (RO) system. Results show that Dow's 16 –inch RO treated water quality is comparable to or better than Bedok RO water.

System configuration and operating conditions

The Bedok NEWater Plant is owned and operated by PUB and parallel trains of 8–inch and 16–inch BW modules were installed in October, 2007, to provide comparative performance data in a challenging water reuse application. The Bedok feed water, which contains treated industrial and municipal effluent, undergoes pretreatment by ultrafiltration prior to reverse osmosis. The feed water contains 300 to 500 ppm of total dissolved solids. The temperature is 30°C with only small fluctuations.

Parallel 8–inch and 16–inch trains were installed, each with two by one arrays of 7–module pressure vessels. The modules contain 37m2 and 160m2 (400 ft2 and 1725 ft2) of membrane active area, respectively. The trains are independently computer–controlled to the same average flux and recovery.

Comparative operation

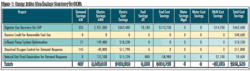

Comparison between the trains shows equivalent feed pressure, pressure drop, and permeate quality, within ranges consistent with normal membrane variation, at the beginning and at the end of the performance period.

On March 4, 2010, after 30 months of continuous, side–by–side operation, the systems continued to demonstrate well–matched performance and provide high quality permeate. Both systems demonstrated overall salt rejection exceeding 97.35. Despite a 4.3 times difference in permeate production, the feed pressures differed by less than 0.3 bar (4 psi).

Increased productivity

The 16–inch DOW FILMTEC modules in operation at Bedok NWF have demonstrated 4.3 times the membrane area and permeate productivity of standard 8–inch modules, with no degradation in permeate quality, no increase in specific power consumption, and no difference in cleaning regimen.

The results validate the considerable economies of scale made possible by the 16–inch format.

Dow Water & Process Solutions offers a broad portfolio of ion exchange resins, reverse osmosis membranes, ultrafiltration membranes and electrodeionisation products.

These products have strong positions in a number of application areas, including industrial and municipal water, industrial processes, pharmaceuticals, power, residential water and waste and water reuse.

www.dowwaterandprocess.com

More Water & WasteWater International Current Issue Articles

More Water & WasteWater International Archives Issue Articles