Fluence completes production of MABR modules from China factory

MELBOURNE, Australia & NEW YORK, SEPT 28, 2017 -- Fluence Corporation Limited, a global leader in water and wastewater treatment solutions, today announced that it has successfully produced the first Membrane Aerated Biofilm Reactor (MABR) module in its newly-built production facility in Changzhou, Jiangsu Province, China.

The spiral production line was developed and tested in Israel with all required machinery and equipment shipped and successfully installed in the Changzhou facility. The plant is now fully operational and ready for the mass production of MABR modules.

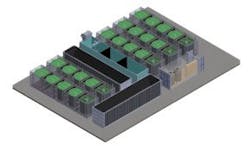

In addition, part of the production at the plant is exclusively dedicated to the assembly of MABR modules in containerized form to deliver Containerized Smart Packaged MABR (CMABR) units. CMABR being containerized enables a faster path to plant commissioning and thereby revenue recognition. The Company expects to ship these Smart Packaged MABR units to meet growing rural wastewater treatment demand in China, and other markets across the globe.

The first spirals and the first MABR module (comprising 2 spirals) from the plant have been produced. The Company intends to ramp production capacity in the coming months to meet growing market demand in China. The planned capacity of the first production line is 7,500 MABR modules annually, which corresponds to approximately US$75 million (A$100 million) in potential annual sales.

A second production line can be added if required and at low capital expenditure cost, to increase throughput to meet growing demand.

The Changzhou facility has the planned capacity to produce up to 2,500 CMABR units each year. To ensure the high quality of each MABR module and CMABR unit produced, a sophisticated semi-automated test station is now operating to test each unit as it is manufactured at the Changzhou plant.

Henry Charrabé, CEO of Fluence, commented, "Successfully producing the first MABR module in our Changzhou factory marks another key milestone for us. As anticipated, we remain on track to supply cost-optimized MABR & CMABR products for future demand both to the China market and globally. We believe the ability to meet demand through local production gives Fluence a significant competitive edge over our peers, because it keeps our costs down and allows us to fulfill orders rapidly. We look forward to ramping our production to further meet growing market demand."

RELATED ARTICLES

Fluence $100m water project in Africa to include “smart intake”

Fluence targets rural China after RWL Water/Emefcy merge

VIDEO: MABR tech is “moving the needle” - Henry J. Charrabé, CEO of Fluence Corp