‘Washout’: Stormwater’s Dirty Little Secret

By Robert Y.G. Andoh

With increasing urbanization, the problems of stormwater runoff from impermeable surfaces have become more apparent. Runoff often carries a high sediment load, and this, along with other associated pollutants, can have a detrimental impact on receiving watercourses. Government has created regulations designed to curb the impacts of stormwater runoff, and the industry has responded with a generation of “flow-through” stormwater treatment devices that remove sediment and other pollutants from the outflow.

Although these treatment devices tend to be effective at removing pollutants under low-flow conditions, they don’t always hold what they catch. When flows reach moderate or high levels, runoff has been known to resuspend and discharge previously captured pollutants and carry them downstream. This phenomenon is known as “washout.”

In recent years, various configurations of proprietary flow-through stormwater treatment devices have evolved, designed with the intention of removing sediment, trash, oils and other pollutants from stormwater runoff, especially in urban hot spots. These devices can be broadly classified as follows:

- Gravity Sedimentation Devices (GSD): These rely on simple gravitational settlement to perform their treatment functions.

- Simple Vortex Separators (SVS): These rely on enhanced gravitational settlement to perform their function, through the use of a rotating flow field. Flow rotation results in extended particle residence times, and increased opportunity for settlement to take place.

- Advanced Vortex Separators (AVS): These operate in a similar manner to simple vortex separators but use specially designed internal components to control and enhance performance and provide isolated storage zones for captured pollutants.

Studies of proprietary treatment chambers have tended to focus on performance in terms of pollutant removal efficiency under conditions up to their “design” flow rates. However, the question of overall performance, including the ability to retain previously captured material when operated within and beyond their design flow ranges, has generally been neglected.

Though removal efficiency is a good indicator of a device’s effectiveness in terms of separating pollutants from stormwater, particularly under low-flow conditions, it does not provide a complete description of device efficacy, especially in terms of its ability to retain previously captured pollutants under moderate or high flows.

In a recent study at Liverpool University in the United Kingdom, the effect of chamber design on performance was considered, focusing particularly on the ability of chambers to retain stored pollutants.

Multiple Configurations

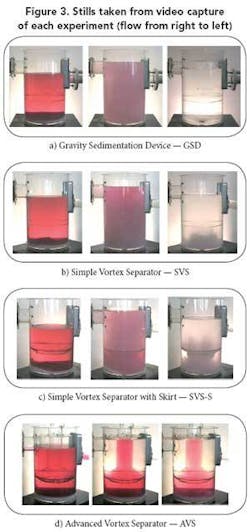

Four configurations were considered in the study. They were selected to represent the general features of some of the systems that are used in practice, ranging from a simple catch-basin design to an advanced hydrodynamic vortex separator (see Fig. 1).

Each chamber was initially filled with water colored with Rhodamine-T dye. A known volume (4.0 liters bulk) of “Styrocell” (Shell Chemicals unexpanded polystyrene beads) grade R743 was allowed to settle evenly on the base of each system. Styrocell R743 beads have a mean density of 1,035 kg/m3 and a D50 of 560 microns, giving an equivalent settling velocity to 75-micron sediment particles with a density of 2,650 kg/m3 settling in water at 10°C. This material is therefore useful as a fine sediment simulant. It is also convenient for experimental studies, as it is readily captured by straining through a very fine mesh filter bag.

Once primed, as detailed above, retention efficiency testing was undertaken by pumping clear (i.e., non-dyed) water into the chambers at a constant flow rate of 32 gpm (corresponding to a hydraulic loading rate of 21 gal/min/ft2). Over a 5-minute test duration, re-entrained particles were collected at the outlet using a filter bag. Flow was measured by means of timed collection of a known volume from the effluent pipe in a calibrated vessel. In addition to collecting numeric data, a video record of each test was obtained.

Retention Efficiency

The retention efficiency of the chamber configurations measured the percentage of solids volume remaining in the pump after solids were allowed to escape for five minutes.

The results were broad, with virtually all the solid material being flushed out from the GSD configuration and nearly 100% of the solids remaining in the AVS. The SVS configurations retained 50%.

For the GSD, the perpendicular orientation of the inlet resulted in the formation of a vertical plane orientated circulating flow in the chamber, sweeping horizontally from the inlet and then down the opposite wall into the sump. This created turbulence in this region, such that solid material was swept upwards from the base and to the overflow. At the end of the test, no solid material was left in the chamber and all the dye had been washed out.

The SVS configuration was also found to exhibit high levels of sump turbulence. In this case, the vortex flow in the chamber had the effect of drawing solid material toward the center and then upwards into the main flow, from which point much of it exited the chamber. At the end of the test, the dye had been washed out, but a proportion of the solid material remained, showing that the liquid exchange rate exceeded the re-entrainment rate. However, the solid material that had been retained was largely in suspension and was therefore vulnerable to further washout.

The SVS-S configuration, which incorporated a skirt that partially sheltered the sump, behaved in a similar manner to the SVS. Given the presence of a circular opening in the center of the skirt, the core of the vortex was allowed to penetrate into the sump with the effect, as previously, of drawing solid material upwards into the main flow (see Fig. 3c). Again, dye washout rate exceeded re-entrainment rate, but overall retention performance was very similar.

The AVS exhibited distinctly different characteristics from the other types of chambers. In this configuration, the internal components prevented excessive flow penetration into the sump region, resulting in minimal disturbance of the stored solid material. Retained solid material was not in suspension and was therefore unlikely to be re-entrained and washed out. In addition, a substantial proportion of the dye was found to remain in the sheltered regions of the chamber during the 5-minute period of the test. Hence, this system is shown to have solute as well as solids retention capabilities.

Making the Case for Retention Efficiency

Retention efficiency has rarely been given full consideration probably because the focus has been on removal efficiency and also possibly due to a combination of lack of awareness and appreciation of its significance. This situation may have been sustained due to a general lack of well-defined protocols for determining retention efficiency in the field. Difficulties associated with determining retention efficiency in the field arise due to the fact that retention efficiency is dependent not only upon hydraulic loading rates, which in practical operation are time-dependent, but also on the quantities and characteristics of the stored pollutants.

Earlier studies using an analytical model in a similar system to those examined experimentally here clearly showed that, in a well-designed vortex separator, the storage region was effectively decoupled from the main flow and could be described as a “slow-exchange region.” More recently, studies have used computational fluid dynamics (CFD) simulation to evaluate different treatment chamber designs, looking at both removal and retention efficiencies. The main findings confirm the relevance of retention efficiency as a performance parameter, highlighting the importance of sheltering the pollutants storage region in such systems.

The principal observation and inference from earlier studies and current work is that stormwater treatment chambers that use sedimentation and inertial separation effects need to be designed to minimize the scope for resuspension (re-entrainment) and washout of captured pollutants. This study confirms that chamber configuration and placing of internal flow-modifying components have a major bearing on device efficacy.

About the Author:

Prof. Robert Y.G. Andoh is the Director of Innovation for Hydro International (Portland, ME). He is responsible for product research and development, technical support, intellectual property rights, marketing and IT. He joined Hydro in 1992 and has over 25 years of experience in the water industry.

Acknowledgments

The author would like to thank the following individuals for their assistance with this article: R.M. Alkhaddar, Liverpool John Moores University (Liverpool, UK); M.G. Faram, Hydro International (Clevedon, UK); P. Carroll, Hynds Environmental Systems Ltd. (Auckland, NZ).