On the Waterfront: Innovative Technologies Support a Revitalizing Urban Environment

By William E. McMillin

For over 100 years, the New Jersey communities of Hoboken, Weehawken, Union City, and West New York on the Hudson River were considered an unsightly port area characterized by working docks and dirty water. This same area is currently experiencing high-level growth and development along the waterfronts. The North Hudson Sewerage Authority (the “Authority”) is helping through the implementation of combined sewer overflow (CSO) controls by employing traditional methods and innovative technologies.

The Authority is working with the communities and developers to implement CSO controls that do not compromise the aesthetic appeal of their vision for riverfront revitalization. By combining outfall consolidation with innovative solids/floatables (S/F) control technologies, the Authority will comply with a state permit requirement to eliminate discharges of solids and floatables greater than a half inch in diameter. A key component of the effort is the employment of a patented S/F-controlling technology by CH2M HILL.

A Revitalized Urban Community

Hudson County waterfront communities have served as a vital seaport that was dominated by docks, warehouses, and railroad terminals most famously pictured in the movie On the Waterfront. The imagery of a working waterfront is being replaced by high-rise condominiums, esplanades, fountains, outdoor cafes, fishing, and weekend relaxation as the riverfront is being transformed into a residential and recreational neighborhood. Once-derelict piers have been transformed into vast fields of green while inaccessible shorelines are now tree-lined esplanades. Historically fenced-off commercial and industrial properties are now gated communities with million-dollar views of New York City.

However, these communities are served by a combined sewer system that is well over 150 years old. The original sewer system was constructed not only to improve sanitary conditions in a growing metropolitan area but also to drain wetlands that eventually became vital parts of the cities. Wooden remnants of the original sewer systems in Hoboken still convey sanitary and wet weather flow towards the waterfront. Other parts of the system serve communities atop the Hudson River Palisades, more than 150 to 200 feet above sea level.

And typical of old urban communities, trunk sewers that once discharged directly to receiving waters are now intercepted by larger sewers and conveyed to the Authority’s wastewater treatment plants. During wet weather, the system is overwhelmed by the high level of runoff flow from this highly urbanized environment and still overflows to the Hudson River at a number of outfalls.

Challenge Is Presented

The Authority is working toward complying with a permit requirement, the first in a phased approach to long-term CSO control planning by the state of New Jersey. The permit requires that all CSOs be screened or otherwise treated to eliminate the discharge of solids and floatables greater than a half inch in diameter. The permit requirement applies to all CSO discharges, including those along the revitalized waterfront in Hudson County. Several of the Authority’s outfalls discharge from underneath the newly constructed esplanade in Hoboken, while others are situated amongst planned development. The Authority was thus presented with unique design challenges in implementing S/F controls that fit into the community’s vision.

The Authority was tasked with implementing S/F controls on sewer system components with widely different drainage areas, performance characteristics and site conditions. All areas are highly urbanized with imperviousness approaching 90%, hence generating high runoff volumes during rain. Low-lying areas of Hoboken experience low conveyance velocities and tidally influenced discharges. Other drainage areas are almost 200 feet above sea level with conveyance down steep slopes to sea level outfalls. Peak CSO discharges range from 80 million gallons per day (mgd) to as much as 800 mgd.

The Authority thus approached each outfall as a unique project while striving to employ common designs. Primary goals were to deploy its capital, operation and maintenance resources cost-effectively while making as little impact as possible on the developing waterfront. Several S/F control technologies had begun to be marketed around the country and especially in New Jersey where the screening requirement is required of all CSO permittees. However, many of these technologies require messy maintenance that would not fit in with the residential, commercial and recreational uses of the waterfront, rain or shine. Many alternatives were researched, but none could meet the Authority’s performance objective with minimal aesthetic impact.

“We needed to install controls that would fit into the Gold Coast waterfront of Hudson County,” said Fred Pocci, the Authority’s Executive Director. “We knew we may be facing increased costs of a custom design compared to other technologies out there, but we needed a system that would be aesthetically acceptable to the community.”

The Authority was thus challenged with developing a new technology that could be constructed within an existing and newly developed waterfront and its uses. After several design iterations, a new S/F control technology was developed for application to a wide variety of performance goals.

New Design

CH2M HILL formed a research and development team of engineers and scientists from various backgrounds in planning, design, construction and operations. The design objective was to have minimal aesthetic impacts, no bypass, and below-ground maintenance to minimize nuisance impacts on nearby waterfront developments.

The primary goals of the new technology are to minimize head loss, maximize the capture of S/F and facilitate maintenance. The new S/F control technology designed and patented by CH2M HILL combines baffling and screening to minimize head losses throughout its performance range. Another unique feature of the design is its self-cleaning capability. In order to be applied to many of the Authority’s outfalls, the design is modular and can be expanded to treat increasing design flows. Finally, the design features common components that can be easily serviced and maintained at all locations.

After establishing performance goals, a physical prototype was developed and computer modeling was conducted to optimize the design. Rigorous testing ensured that the design would meet all goals.

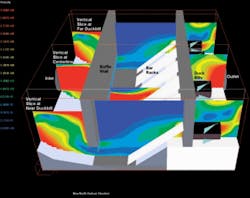

Alden Research Laboratory of Holden, MA, constructed a physical prototype model of the design. The prototype featured baffles and screens with pumping capabilities to simulate wet weather flows. The physical dimensions of the baffle and screening chamber were altered until a balance was achieved to minimize head losses. Meanwhile, the angle of the screens was adjusted to identify an optimal angle that would induce circular velocities in the chamber and tangential velocities across the screens, allowing for self-cleaning. The technology was tested using floatables typically found in combined sewer flows during wet weather, namely small candy wrappers, coffee cup lids, sandwich bags, water bottles, and polystyrene products, including cups and plates and paper products.

CH2M HILL also conducted computational fluid dynamics (CFD) modeling to test and optimize the technology in parallel with prototype testing while also confirming that head losses would be minimized in specific design applications. The CFD model used by the design team was Phoenics, developed by Concentration Heat and Momentum Limited (CHAM) in London, England. Model simulations led the team to select a design that minimized entrance and exit losses while maintaining self-cleaning capabilities.

Design Features

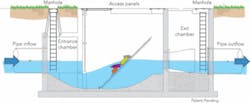

The system typically consists of a below-grade screening chamber that is hydraulically optimized to promote self-cleaning during wet weather events. Parallel screening chambers meet flow objectives, provide redundancy, and enable isolation for cleaning. The technology features an entrance chamber to slow velocities and distribute flow evenly between the parallel screening chambers. The screening chambers feature angled screens that are self-cleaning while preventing the discharge of floatables larger than half an inch. In tidally influenced locations, flap valves prevent tidal inflow.

Each screening chamber has been designed to optimally operate at 80 mgd, with a consideration for screen blinding. Since the design is modular, the design is employed to treat beyond design flows in multiples of 80 mgd. One chamber is added for redundancy. In some locations, one chamber is sufficient for the design flows; therefore, two were installed. Some S/F facilities require six or eight chambers.

Following a wet weather event, chambers are serviced from street level with a vaccum truck or can be equipped with a sump pump to remove captured materials. Most important, there is no unsightly debris removal. In addition to providing an aesthetic solution consistent with revitalized waterfronts that avoids unsightly services in public places, it also eliminates man entry into deep chambers, thus providing a safe working environment.

Deployment

The Authority has since constructed, and is now operating, the patented technology at several of its CSOs. It is ideal for deployment at CSO discharges where overflows are infrequent yet still require a minimum level of treatment to protect aesthetics.

One facility was constructed adjacent to the Lackawanna Terminal in Hoboken, which handles tens of thousands of daily commuters to and from New York City, and thousands of weekend waterfront enthusiasts. Another has been constructed amidst multimillion dollar condominiums that are currently under construction. The only aboveground facility combines the technology with exterior design to blend into the backdrop of the Palisades and the community. Several more facilities are presently under construction.

“They work,” Pocci said, adding, “I originally doubted the cost-effectiveness of the permit requirement to capture floatables. But after seeing the amount of material captured in each chamber after a rainfall, it is clear that there will be an improvement in the water quality along the waterfront. Operation and maintenance is a little intensive after events, but the overall cost is affordable. There are no odors and no mess. The technology is a winner for the Authority and the community.”

About the Author:

William E. McMillin Jr., P.E., is a Senior Technologist with CH2M HILL’s Water Business Group in Parsippany, NJ.