Cardiff WwTW Aeration Optimisation through Scientific Control

By V. Bodington, A. Langford, M. Dooley and K. Diamond

• Optimising activated sludge processing, instrumentation from Strathkelvin Instruments Ltd. helps Kelda Water Services reduce aeration costs of the Cardiff Wastewater Treatment Works by over 20% and save over £300.000 in energy costs.

Figure 1. Product Model Showing Process Followed in Developing Cardiff WwTW OptimisationABSTRACT: Aeration optimisation of a 16 basin SBR plant running in ICEAS (Intermittent Cycle Extended Aeration System) mode was undertaken by changing operating parameters from the traditional design of dissolved oxygen (DO) control to a scientific approach using respirometry. Measuring the critical oxygen point (COP) for carbonaceous and nitrification bacteria and combining this with in-situ Oxygen Uptake Rate measurements forms the basis of supplying only the correct levels of oxygen for the required amount of time to break down influent BOD and ammonia levels. These measures can be used to calculate when treatment is complete and therefore tailor energy requirements of the site to suit aeration supply needs. Resultant changes have led to sustainable operational savings of over 20% of aeration energy consumption and reducing carbon emissions whilst maintaining compliance.CARDIFF, Wales, UK, Sept. 30, 2009 -- This paper discusses an overall product model that combines a number of pieces of equipment, the expertise of scientists and consultancy support to optimise the aeration process of the activated sludge treatment plants of Cardiff & Afan Wastewater Treatment Works (WwTW), and initial investigations of other top energy sites. This was achieved using an innovative, cutting edge technology saving Giga Watt hours of energy and assisting Dwr Cymru Welsh Water (DCWW) and Kelda Water Services (Wales), or KWS(W), in reducing their carbon footprint. The scientific equipment used by the project was obtained from Strathkelvin Instruments along with its consultancy support working together with the KWS(W) Operations and scientific project teams to deliver savings.

Balancing supply and demand and ensuring sustainable methods is vital to the future of our environment. Water companies use many different methods to treat sewage. One method that is used is activated sludge treatment; this has a massive energy demand as air is pumped from large blowers into the treatment process. All sewage has an oxygen demand and it's this demand that we want to supply. The treatment process uses bacteria which biodegrade the incoming sewage as food and removes the organic carbons and ammonia from the sewage. It's essential that they receive a supply of oxygen or else they cannot respire resulting in them dying and resultant discharge of untreated sewage to the environment. Therefore, to ensure treatment is complete an excess amount of air is pumped into the process, which can be very inefficient and costly under existing methods of dissolved oxygen (DO) control. With the prospect of increasing power prices, and the importance of reducing carbon emissions a sustainable solution to this problem must be found.

Product Model

The product model involved a scientific approach to measuring the baseline results, boundaries and the scope for change for optimisation by understanding the normal operating conditions of the plant. Once these parameters were identified, a step by step optimisation programme with built in safety margins could commence through the changing of these operational conditions. The model enables us to make changes in real time and provide a quick feedback response with immediate management of risk to compliance.

The two main pieces of equipment used during the trial and implementation of the product model were the Strathtox and AS Bioscope. The Strathtox is laboratory based and used to conduct a range of temperature controlled tests on activated sludge samples, so it can mimic the conditions of the treatment process. It's portable so that it can be used on other sites to determine the individual treatment process characteristics. The AS Bioscope is used in-situ in the activated sludge plant and can be used to measure the Oxygen Uptake Rate (OUR) and DO over a range of varying site conditions such as loading and temperature.

Figure 2. Picture of an AS BioscopeFigure 3. Picture of a Strathtox

The AS Bioscope and Strathtox testing used in conjunction with each other, provide the following vital information before starting the optimisation process:

• Critical oxygen points (COPs) tests -- minimum level of dissolved oxygen required

• Respiration rates - rate of oxygen consumption for biodegradation

• Oxygen uptake rates -- actual oxygen consumed

• Biochemical oxygen demand (BOD) short term -- level of treatment

• Carbonaceous / nitrification inhibition -- measurement of toxicity

• Nitrification rates (%) -- amount of ammonia which can be degraded

• Bacterial health monitoring tests -- quality of population

These features provide us with the information on the level of oxygen required for maintaining the process and measuring the amount of oxygen that is wasted. The Strathtox and AS Bioscopes have the facility to measure the actual design parameters of the plant such as percentage oxygen used separately by carbonaceous and nitrifying bacteria.

The project was started with the potential of saving 30% of aeration costs, which for Cardiff WwTW was around £300.000. The savings would reflect in reduced operating costs, and CO2 emissions giving better value for all DCWW customers.

A key feature of the product model was the transfer of knowledge between the consultancy staff from Strathkelvin Instruments and KWS(W).

Trial and Optimisation Process

This started with an initial assessment followed by a three month trial project from July 2008 on two of the 16 SBR treatment basins at Cardiff WwTW and consequently the start of the implementation process with full roll out by March 2009. This was achieved by implementing a team to join both Strathkelvin's knowledge of its equipment and its application, with KWS(W) operational knowledge of the treatment plant to deliver a specific optimisation process.

Figure 4. Optimisation Factors at Cardiff WwTW Operation

The initial testing carried out before the trial in July showed that optimisation was possible on the site at Cardiff and therefore during the trial period on two of the 16 basins, the product model was followed introducing a step change program. The key to the step change program was calculating the COPs for both carbonaceous (BOD consent) and nitrification (ammonia consent) bacteria to provide us with our optimisation boundaries for the implementation process.

Figure 4 shows all the factors considered before optimisation can be implementated, but it's important to note that optimisation is only possible within the design constraints of the existing treatment plant. Each one of the points are important in maintaining compliance of the site and understanding the optimisation process.

The plant was designed by ITT for a population equivalent of 880,000, the EA consent conditions are 50 mg/L BOD, and 20 mg/L ammonia, with an upper tier of 250 mg/L of total suspended solids (TSS). Urban Waste Water Conditions also apply at Cardiff WwTW with consent limits of 25mg/L BOD and 125 mg/L chemical oxygen demand (COD). The site treats a maximum flow of 523,584m³/day.

The incoming sewage enters the sequencing batch reactor (SBR) plant via four inlet screens, and then fed via the distribution system to the treatment process. The plant has 16 basins split equally into two phases which then aerates the incoming sewage for a set amount of time prior to the next stage in the process of settlement before finally the clean liquors are decanted off to be discharged into the Bristol Channel 4.5km offshore. In each flow mode, aeration lasts for 50% of available cycle time, settlement for 25% and decant for 25%.

Figure 5. Cardiff WwTW Respiration Rate vs. Dissolved Oxygen Depicting Critical

Discussion

Figure 5 shows the difference between the carbonaceous and nitrification COP. Under traditional parameters of activated sludge the plant would normally be set up to control to 1mg/L and 2mg/L of oxygen respectively. The COP at Cardiff WwTW for carbonaceous bacteria was calculated to be 0.8mg/L and the COP for the nitrifying bacteria was 3.5mg/L (see Figure 5). When the air being supplied to the treatment process increases the dissolved oxygen well above the COP for either carbonaceous or nitrification excess energy is being used to deliver air that is not required for treatment, (shown as energy waste in Figure 5). The figure also shows that if the amount of air supplied to the treatment process falls below a certain level it can cause bacteria stress resulting in the treatment process being affected and risking compliance. Therefore, calculating the COPs linked with the optimisation features outlined in Figure 4 gives us our product model boundaries, creating a sustainable method of aeration optimisation by controlling air flow into the treatment basin.

The COP shows the minimum level of DO required by the bacteria for ingestion, respiration, growth and division; and, thus, it's vital that the correct amount of air is delivered to the treatment basins. If the amount of oxygen is below the COP the bacteria will become inhibited and will not be able to grow, therefore treatment and compliance will be affected or lost completely. During the project the COP was calculated for both the carbonaceous and the nitrifying bacteria, this is important as carbonaceous bacteria break down the BOD first as these molecules are smaller and therefore are much easier and quicker to break down and require a lower amount of oxygen to complete this task. The nitrifying bacteria absorb up the ammonia that's within the incoming sewage and oxidise the ammonia to provide energy required for growth, this process is known as nitrification. This process is carried out by two different species of bacteria: Nitrosomonas, which oxidise ammonia to nitrite, and Nitrobacter, which oxidises nitrite to nitrate. This process of ammonia oxidisation requires an increased amount of oxygen as this process is relativity inefficient chemical oxidation and, therefore, requires a greater amount of oxygen giving a higher COP.

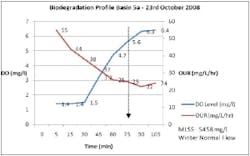

Figure 6. An Example of a Biodegradation Profile in Winter Flow Mode

Once this stage was completed, ammonia and short term BOD profiles were conducted on the two trial basins to understand the flow distribution of untreated sewage across the basin, due to it running in ICEAS (Intermittent Cycle Extended Aeration System) continuous feed mode. Biodegradation rate profiling is normally carried out on plants that operate with a continuous flow footprint or on a time basis for SBRs. An SBR operating in ICEAS mode, however, requires assessment against both a continuous flow footprint and time basis. In addition, the basins need to be assessed during settlement and decant to determine the extent to which untreated influent infiltrates the basin.

It was decided that measurements should be sampled across what the site operators determined to be the best case (Basin 6a) and the worst case (Basin 2a) scenarios. During the settlement and decant phases of the cycle samples were gathered on a time and footprint basis. These samples were returned to the laboratory and tested for ammonia expressed as N levels and the level of BOD determined using the BOD (short term) protocol provided by Strathtox system using basin Endogenous settled activated sludge. These would give a measure of how far the untreated load progressed across the lagoon during non-aerating cycles.

The data gathered during the aeration, settlement and decant cycle identified little change in BOD load during the non-aerating phase of the cycle. This data would support a theory that the influent flow is laminar along the bottom of the basin during this part of the cycle giving increased opportunity to extend this part of the cycle time.

Figure 6 shows an example of the biodegradation profile of Basin 5a at Cardiff WwTW on Oct. 23, 2008, in winter normal flow with an aeration time of 108 minutes. It can be seen that treatment is complete when the OUR (red line) flattens out. This is indicated on the graph by the vertical black dotted line (also seen in Figures7& 8). The biodegradation profile was repeated over many different aeration cycles covering different flows to assess all conditions.

Figure 7. An Example of a Biodegradation Profile in Summer Flow ModeFigure 8. An Example of a Biodegradation Profile in High Flow Mode

This graph in Figure 9 shows the reduction in ammonia concentration across the aeration cycle. Inlet Ammonia levels were 12mg/L and combined discharge sample was measured at 4mg/L.

Linking the data collected from the ammonia and BOD (short term) tests with the biodegradation profiles collected using the AS Bioscope determined that the aeration cycle time could be reduced initially by 16% with a built in safety factor.

Figure 9. Ammonia Profile across the Basin over the Aeration Cycle

By tailoring to the needs of the bacteria we have created a sustainable method of operational control for aeration, resulting in reduced operational expenses, energy consumption and CO2 emissions. Since introduction of respirometric control at Cardiff WwTW, aeration cycle time under high flow mode and winter flow mode has been reduced by 15 minutes and 18 minutes respectfully, with the potential to reduce the aeration cycle time during summer flow mode by 20 minutes.

In addition, further savings are predicted following the summer flow mode that's still to be assessed due to poor weather conditions during summer 2008 and re-introduction of the return activated sludge (RAS) control option which will enable us to utilise another 10% of basin volume, enabling further aeration reductions.

Benefits & Developments

The trial started in July 2008 for three months. And, from the end of September 2008, the product model was rolled out to the remaining 14 treatment basins at Cardiff WwTW. By the end of December 2008, 50% of the site had the reduced cycle time implemented into the SCADA system. The roll out continued until the end of March 2009. Due to the success at Cardiff WwTW, the product model was used to investigate the remaining top energy usage sites to see if there was any possibility of optimization -- and, so far, Afan WwTW has had six out of eight basins optimized in the same manner.

The unique feature of the AS Bioscope is that it uses real-time, site-specific monitoring and that it can measure the oxygen uptake rate of the microorganisms in the treatment process within a matter of minutes, meaning that any optimisation program is unique to that site taking into account process loading conditions. The Strathtox has unique software that calculates the COP, which is key to developing an optimisation program as you can see what the bacteria are doing, "taking the guess work out of optimisation". Also the AS Bioscope was new to the market. Strathkelvin Instrument had newly developed this technology/concept and KWS(W) was the first water company to use this full product model linking the data from the Strathtox, AS Bioscope and the company's experiences to develop the optimisation product model.

The unique feature is that the whole product model is a new innovative approach to activated sludge treatment process. The main reasons for this product model being such a success are:

• New innovative approach

• Delivering sustainable energy savings & reductions in carbon footprint.

Figure 10. Cardiff WwTW EA Sample Results• Process optimisation based on scientific approach giving confidence in changes introduced.

• Managing compliance at every step in the process, by supplying the actual oxygen demand to meet final effluent compliance

• Better performance measurements of activated sludge plants.

The key non-financial benefit to the business is that, by tailoring oxygen supply to the needs of the bacteria, the amount of carbon emissions of the site have been reduced. Therefore, by calculating the COP and using the oxygen uptake rate, a more sustainable method of managing the treatment process providing more for less and ensuring compliance (see Figure 10) has been achieved.

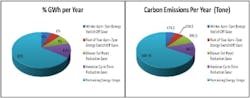

Through respirometeric control, the team has delivered an annual 5.7 GWh reduction in aeration energy costs equating to 26% energy saving on Cardiff WwTW and Afan combined, Cardiff alone saves 3.9 GWh. Total CO2 emissions have been reduced by 2.994 tonnes per year, equivalent to driving around the world 1.300 times. This saving plus the potential further roll-out to other KWS(W) sites around South Wales has a demonstrable savings to the customer, DCWW. In addition, DCWW's initial investment has a six month pay back. Figure 11 shows each area of the optimisation program that contributed to the 3.9GWh saved at Cardiff WwTW as well as the annual carbon emissions saved and remaining carbon emissions.

Another benefit is that the knowledge transfer has been retained within the company for future development of the product model, as well as among KWS(W) staff development. This transfer of knowledge also has been shared in the wider KWS business, United Utilities Operational Services (UUOS) and the other Asset Management Alliance (AMA) partners for use with other project development and process, and the Strathtox is being used to assess the impact of the centrate from our advanced digestion projects on our activated treatment process, and helped assess impact of toxicity threatened by third party intervention.

Figure 11. Annual Percentage Energy and Carbon emissions

Conclusion

The respirometric method of controlling the aeration at Cardiff WwTW is leading the way in developing a new operating control philosophy for Kelda Water Services (Wales) by implementing a new more-for-less way of working -- saving energy, reducing operational costs and CO2 emissions, whilst also ensuring compliance. Delivering a project with a six month payback also goes beyond company requirements and achieving benefits in three areas of the business: 1) Reducing energy usage for the site drives down operational expenditures for KWS(W), which 2) reduces the cost for its client, Dwr Cymru Welsh Water, and, in turn, 3) DCWW can demonstrate that it's using its customers' money more wisely and that it's striving to operate a greener business by reducing energy usage and carbon emissions. Therefore, this project also helps DCWW achieve its company policy by reducing the amount of energy required for aeration treatment of any incoming sewage. This method of optimising the bacterial treatment process not only saves energy and money at Cardiff WwTW, but the project can be adapted and changed to suit any style of activated sludge treatment, limited only by existing design parameters. WWi

Acknowledgments

The authors would like to acknowledge all the work done by Ian Parry, Eddie Morton, Jim Marsh, James Byrne, Terrence Bennett and others working within the KWS(W) Cardiff Catchment Operations team, ME&I team and the Energy team in helping with many different project areas and without whom the project wouldn't been the success it was. They also would like to thank the technician team from Strathkelvin Instruments Ltd. for their continuing support. This paper was presented at the 3rd European Water and Wastewater Management Conference, organized by Aqua Enviro Technology Transfer and held Sept. 22-23, 2009, in Birmingham, UK.Author's Note: Victoria Bodington and Anna Langford are with Kelda Water Services (Wales), and Michael Dooley and Ken Diamond are with Strathkelvin Instruments Ltd. Dooley is managing director and Diamond sales manager at Strathkelvin, of North Lanarkshire, Scotland. Contact: +44 (0) 1698 730409, www.strathkelvin.com or www.asbioscope.com###