By Henry Alamzad

Founded in 2004, 8 Feathers Distillery produces premium whiskeys from locally sourced grains and water from a nearby artesian well. The company disposes of its grain slurry waste sustainably and economically by separating the grain from water using a centrifugal sifter. The grain is donated to a local farmer as livestock feed, while the water is treated before being safely piped into the public wastewater system.Transport Challenges

The waste produced from the distillation process, called stillage, is about 40 percent grain solids and 60 percent water by weight. The distillery processes 3,000 lbs (1,363 kg) of grain weekly, which produces roughly 7,500 lbs (3,409 kg) of stillage.

A local farmer previously picked up eight 300-gallon (1,136-liter) totes per week of the watery grain mixture, but at 940 lbs (423 kg), the totes were difficult to transport and required covers to prevent spillage. “This wet approach would not scale for higher production,” distiller Greg Lowe said, so the grain needed to be separated from the water. To complicate matters, any water piped to the municipal wastewater treatment system needed to be free of solids content and have a pH in an acceptable range.Evaluating Grain Separation Options

The stillage produced by some distilleries contains grain that remains intact and can therefore be separated from water using a settling and rinsing process called “lautering.” However, the fine grain particles resulting from the grinding process employed by 8 Feathers precludes lautering as a means of separation.

Flocculation was also ruled out because the process requires the use of chemical additions to cause particles to clump, which would render the dewatered grain unsafe as animal feed.

Mechanical separation emerged as the logical choice. Options included filter presses, screw presses, circular vibratory screeners and centrifugal screeners, Lowe said.“Initially, all mechanical options appeared as viable choices. The filter press offered excellent performance but the cost of the press, air diaphragm pumps to fill the press, and a compressor to run the pumps put the total cost at more than double that of a screw press or centrifugal separator,” Lowe said. “Further, without adding some form of chemical solids coagulator into the flow, the filter cloths would require extensive cleaning after each use. Chemical use would also contaminate the recovered grains sent for feed and raise the cost of continuous operation to an unacceptable level.

“We also considered screw presses, but smaller units that fit our budget and footprint were unavailable,” Lowe said. “This narrowed our choices to mechanical sifter-type separators.” Kason Corporation manufactures both circular vibratory and centrifugal screeners, so 8 Feathers provided the company with a 10-gallon (38-liter) sample of stillage for testing on both machine types in its laboratory.

The circular vibratory unit proved unable to handle the 50 gal/min (189 L/min) infeed rate required for the stillage pump capacity but the centrifugal screener handled the flow rate with capacity to spare.

8 Feathers purchased an MO-SS Centri-Sifter™ model with a 140 mesh (105 micron) heavy-duty reinforced stainless-steel screen to provide effective separation and minimize the risk of screen blinding.Installing the Sifter

The results were as good as or better than anticipated.

According to Lowe, the sifter processed a 1,500-gallon (5678-liter) test sample with 40 percent solids, fed at 40 gal/min (151 L/min) without any degradation of performance. “The separated grain was at an acceptable level of dryness for transport,” he noted. “After the test run, the unit was opened to inspect the screen for evidence of blinding and none was found.”Centrifugally Separating Grain

from Water

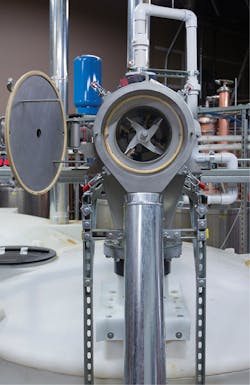

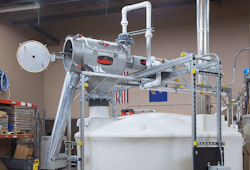

Installed 8.5 feet (2.6 m) above the plant floor, directly over the vat that receives the water, the unit measures 21 inches (533 mm) wide, 32.8 inches (832 mm) tall and 74.8 inches (1,899 mm) long, including its 3 hp (2.2 kW) motor.

The water/grain mixture is fed by a lobe pump into the inlet at the upstream end of the centrifugal sifter, where a screw feeds the mixture into the open end of a horizontal screen cylinder. Rotating helical paddles propel the water/grain mixture against the screen, accelerating the passage of water through the screen and against the wall of the chamber, which funnels the water by gravity through a 10-inch (254-mm) outlet into a 2,000 gal (7,570 L) polyethylene vat below. It is further treated with soda ash to adjust pH before finally flowing into the public wastewater system.Grain solids unable to pass through screen apertures are propelled in a helical pattern through the screen cylinder until being discharged through its open end into a chute that funnels the dewatered solids into a plastic tote on a pallet below. When a tote is full with about 2,500 lbs (1,136 kg) of the damp grain, a pallet truck replaces it with an empty tote. The full totes are stored in a holding area to be picked up by a farmer.

The screener separates 22 to 33 gal/min (83 to 125 L/min) of 40 percent solids (by weight), Lowe said. “For our solids content, the optimal rate is 20 to 25 gal/min (76 to 95 L/min).”

Cleaning and Maintenance

The centrifugal sifter’s end housing can be opened, allowing tool-free removal of the screen cylinder and paddle assembly from the cantilevered shaft for cleaning. However, operators simply backwash the sifter with water as it runs, cleaning the pipes and the screens at the same time. “It takes two or three minutes and has worked well, eliminating the need to climb a ladder and physically access the machine,” noted Lowe.

Additionally, no maintenance has been required and no reliability issues have been encountered. “We have not opened the door on that thing in six months,” he said. IWW

About the Author: Henry Alamzad serves as president of Kason Corporation, having previously served as the company’s vice president of sales and marketing. He holds an MBA in marketing from the New York Institute of Technology, an MS in chemical engineering from City University of New York, and a BS in chemical engineering from the University of Rhode Island. Learn more at www.8feathersdistillery.com.

Circle No. 153 on Reader Service Card