WPL awarded retrofit wastewater contract for United Utilities

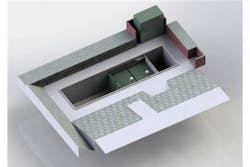

WARRINGTON, UK, JULY 31, 2019 -- WPL has been awarded a contract for permanent replacement of a rotating biological contactor (RBC) at Mowpen Brow wastewater treatment works. WPL’s Hybrid-SAF™ enhanced biological treatment process will be retrofitted into the existing RBC tank at the United Utilities site near Knutsford, Cheshire.

The precision-engineered submerged moving-bed, fixed-film technology was developed in-house by WPL and can be retrofitted into any vessel, regardless of shape or size. WPL’s team worked closely with United Utilities to identify the most effective and cost-efficient solution for the Mowpen Brow works once it was decided to replace the RBC.

By repurposing existing onsite infrastructure, rather than ripping-out and reinstalling the tank, the utility will make significant cost-savings and reduce environmental impact. Disruption to the local community will also be minimized, with fewer vehicle movements required.

The installation will increase total capacity at Mowpen Brow, which serves approximately 300 population equivalent. It will also deliver highly efficient wastewater processing, meeting the descriptive environmental consent.

Andrew Baird, technical director, WPL said, “WPL has worked in partnership with United Utilities for over 20 years and we’re delighted with this latest contract win.

“The modular nature of the WPL Hybrid-SAF means the technology is highly adaptable to existing vessels of different shapes and sizes. At a restricted site like Mowpen Brow, it may be one of few options available.”

A recent installation of WPL’s Hybrid-SAF for Wessex Water at Sherborne wastewater treatment works doubled capacity and delivered a cost-saving of approximately 75% in capital expenditure. In addition, the operator maintenance requirement is low when compared with competitor technologies and there are no moving parts.

WPL has already undertaken the design work for the Hybrid-SAF for Mowpen Brow and the system will be manufactured off-site in factory conditions. Installation takes place in July with commissioning in August.

Baird said, “Water and sewerage companies are under increasing pressure from the regulator to deliver better value for their customers and we are seeing strong interest in the WPL Hybrid-SAF. WPL has a long history of design-for-manufacture-and-assembly (DfMA) treatment systems and trusted partnerships with many UK utilities so we are well-placed to support these objectives.”