Immersed UF membranes help Chinese industry recycle wastewater

The Yanshan Petrochemical Company uses ZeeWeed® membranes for the ultrafiltration pretreatment of secondary effluent from municipal wastewater prior to reverse osmosis in order to produce ultrapure boiler feedwater.

Polluted water or scarce water are the only choices for many people in China when it comes to the availability and quality of this precious resource. China’s Ministry of Water Resources recently reported that more than 300 million residents drink unsafe water and among those, 190 million people drink water with harmful substances that are above acceptable levels. Water shortages are also widespread and are particularly bleak in the north, where 50% of the population, and 65% of the farmland, has access to only 20% of the country’s water.

Industry consumes as much as 70% of China’s water and the Chinese government put a high priority on building more wastewater treatment plants to recycle wastewater and to reduce the environmental damage caused by a lack of effective treatment strategies. China currently treats only about 30% of urban wastewater and is targeting an increase to 60% by 2010. In addition, municipal and industrial wastewater reuse must increase to 70% for all major cities. Such strategies will not only reduce water pollution and provide cleaner drinking water, but will also lessen the tremendous demands Chinese industry places on the country’s dwindling potable water supplies.

Yanshan Petrochemical Company in Beijing is one of the nation’s leaders in adopting advanced wastewater treatment technologies that can recycle wastewater and reuse it for industrial processes. Since August 2003, the company has been using ZENON ZeeWeed® immersed ultrafiltration (UF) membranes to provide tertiary filtration for about 28,800 m3/day of secondary effluent from municipal wastewater. The resulting tertiary effluent is then further filtered by a reverse osmosis (RO) system to produce ultrapure boiler feedwater for the production of polyethylene pellets.

Numerous sites around the world are using ZeeWeed membranes for UF pretreatment prior to RO; however, Yanshan Petrochemical is the first in China to implement such a technology. The process starts by passing secondary effluent through a 1-mm screen. The flow is then distributed among four process trains, each with six ZeeWeed cassettes that are immersed directly into the process water.

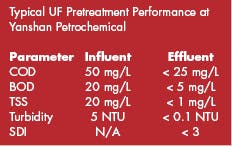

Thousands of reinforced, hollow-fibre membranes hang loosely in each cassette and use a low-pressure vacuum to draw the water through billions of microscopic pores. With a nominal pore size of 0.04 microns, the membranes form a physical barrier against virtually all suspended solids and colloidal materials that may be in the water. Consequently, the Yanshan Petrochemical Company can typically recover about 94% of the water from the wastewater stream and consistently provide high quality feed water to the RO system regardless of variability in the raw water source.

The continuous production of superior quality feed water is a critical requirement to ensure optimum performance of an RO system and to protect it from fouling. By incorporating UF pretreatment, Yanshan Petrochemical Company can significantly reduce the rate of RO membrane fouling and extend the life of RO membrane modules. UF pretreatment also lets RO systems function at a higher operating flux while reducing downtime, decreasing maintenance costs, and lowering operating costs.

Operational costs are further reduced through the automated operation of the ZeeWeed system, which employs several cleaning processes to ensure high membrane performance. Intermittent coarse bubble aeration scours debris from the fibres, while backpulse cleaning periodically reverses the flow of the filtration process and forces filtered water back through the pores to dislodge particles. When necessary, in-situ chemical cleaning can be performed to restore the membrane permeability to optimum levels.

The entire system occupies a fraction of the space that conventional granular tertiary treatment and RO pre-treatment systems would require, which eases space constraints for existing plants that could benefit from a UF retrofit. The compact size of a UF treatment system can also provide significant savings in land acquisition and capital costs. The cost of UF membrane technology continues to fall as systems become more widespread and efficiencies are realised in manufacturing and development.

Water reuse will play a key role in helping China achieve its goals, as the nation continues to move forward with new environmental remediation policies to increase wastewater treatment, reduce water pollution, and deal with its declining drinking water supply. Once simply considered waste, wastewater is now becoming a valuable resource that can provide a lasting, drought-free supply of non-potable water that could someday quench the thirst of China’s continually growing industrial sector.

Author’s Note

Kenneth Lam, the managing director of China, Taiwan and Hong Kong for ZENON Environmental Inc, is based in Oakville, Ontario, Canada.