Colombia's Bello Breakthrough: Self Sufficient Wastewater Treatment

Although blessed with more than adequate water supplies, Colombia's wastewater treatment has been in need of revision. The 432,000 m3/day Bello wastewater treatment plant aims to help clean up the Medellín River and serve 3.2 million people in the region. Mauro Nogarin provides an update on the project, which is now under construction.

In terms of water availability, Colombia is one of the more fortunate countries in Latin America. As a 2010 study by hydrology institute IDEAM revealed, an average water yield of 286,398 m3/km2/yr is available in the country. This is more three times Latin American average water yield (95,466 m3/km2/yr). The recent challenge for Colombia has been coping with the effects of heavy rains and floods.

Furthermore, according to a technical report published in February 2013 by the Colombian Superintendence of Public Works, the sewage treatment system in the country currently suffers from various structural problems.

As part of the report, a total of 333 out of 562 sewage treatment plants in the country (59%) were inspected, between 2011 and 2012. Nearly 90 of the plants were found to not be operating. Among the problems found in the remaining plants, the Superintendence found that many were not meeting the standards for the treatment of wastewater, while others did not know the proper protocols for operation, others lacked maintenance and some were vulnerable to natural disasters.

Q&A interview |

Colombia's EPM (Empresas Publicas de Medellin E.S.P.), known as EPM, is a utility with wide responsibilities. As well as power generation, natural gas distribution, EPM is in charge of providing water and wastewater services for all ten municipalities in the Aburra Valley, where Medellín, the capital city of Antioquia, is located. The other cities serviced by EPM are: Envigado, Itagüí, La Estrella, Bello, Caldas, Copacabana, Girardota, Barbosa and Sabaneta.

EPM's wastewater network consists of 4,080 kilometers of pipes and includes sewage, drainage and combined waters which covers an area of 200 Km² and serves 966,250 residents. The sewage infrastructure consists of 322 kilometers of collection pipe and 34 kilometers of connecting pipe that link the different municipalities of the Aburra Valley. Infrastructure also includes the sewage treatment plant of San Fernando, which treats all the wastewaters from the southern portion of the Aburra Valley, with a treatment capacity of 1.8 m³/s.

Medellín river clean up

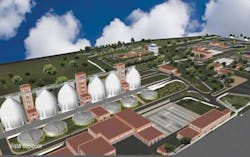

As part of the second phase of development for the cleanup of the Medellín River, work has begun on the Bello Wastewater Treatment Plant (WWTP) in Medellín, in call for a tender Aguas Nacionales EPM de Medellín a subsidiary of EPM.

This new WWTP, when completed, will handle the treatment of 95% of the wastewater from the cities of Medellín and Bello, thus helping to clean the waters of the Medellin River by achieving levels of 5.0 mg/l of dissolved oxygen.

Despite 11 bids being received, a multi-national winning consortium secured the bid. The consortium is made up of HMV Engineering Ltd. and Pöyry Environment GmbH, the latter being acquired by Lahmeyer GKM Consult. Construction of the WWTP is being undertaken by the Spanish-Korean consortium Aguas de Aburrà, an equal partnership between Korea's Hyundai Engineering and Spain's ACCIONA Agua.

Financing for the project comes in the form of a loan for US$450 million provided by the InterAmerican Bank of Development (IBD) to EPM.

Expected treatment capacity of the Bello WWTP will be 120 metric tons a day of industrial, commerical and residential organic waste. It will have a design flow of 5 m3/second and will process more than 75% of residential wastewater, covering 95% of overall water discharged into the Medellin River. The project includes the construction of 7.7 kilometers of interceptor sewers of concrete pipes of diameters between 2.2 and 2.4 meters.

The water treatment plant itself is a secondary treatment facility with activated sludge for treatment of primary and secondary sludge, dehydration of digested sludge and an odor control system. The plant also includes an energy recovery component, which will generate the electricity required to operate the plant, making it entirely self sufficient in energy.

To stabilize the sludge, the Bello WWTP will use six anaerobic digesters, which will maintain the sludge temperatures at 35°C, so that the aerobic bacteria will transform the contents of the sludge into methane, CO2 and water.

After the stabilization process, the sludge is stored in three storage tanks where it will be digested. Methane produced will be used to generate electricity through six generators, which can operate on either methane or natural gas.

Energy produced in these six generators fuels the internal electrical network of the treatment plant and provides 30% of the total electricity utilized at the facility.

In order to recover the methane from the digesters and transfer it to the gas storage tanks and feed the generators, a complete filtration and compression system has been installed, which includes foam traps, ceramic filters and activated carbon, removal of sulfur, drying plant and gas compression system.

Tunnel boring

The construction of the north interceptor duct is the responsibility of the Mexican-Colombian consortium CICE, which is made up of ICA (Ingenieros Civiles Asosiados, S.A.) Cotrisa (Construcciones y Triturados S.A.) of Mexico, and Estyma Estudios y Manejos S.A., of

Colombia. By March 2013, just over the 25% of the tunnel length had been created by the the tunnel boring machine (TBM), drilling at a depth between six and ten meters below ground level.

“Diana", as the first TBM has been christened, has been supplied by German company Herrenknecht, one of three used for the project, in the area known as “Moravia".

It tunneled 417 meters underground during its first run, until emerging into the first of 28 holes drilled along the route to the waste water treatment of Bello. This first length took one month. Another 27 tunnels will be required before reaching the water treatment plant, each measuring between 400 and 750 meters each, which will require 17 months to tunnel and ending in the final tunnel measuring 7.7 kilometers which will enter the plant.

A total of 61,000 cubic meters of earth will be removed, 85% of it using the traditional method, in other words: open excavation. One of the major technical difficulties for the project was that the area in which the tunnels are being drilled are densely populated, in addition to the complicated topography and geological conditions, and include the railroad and subway lines as well as the major highway for the western region.

Although wastewater infrastructure may well be lacking or not running up to full efficiency in Colombia, the new Bello WWTP will hopefully transform the way private partnerships are viewed in the country and clean up the Medellín River. While Acciona Agua's contract may be worth USD$347 million, a price cannot be put on the latter.

Author's note: Mauro Negarin is a freelance contributor for WWi. For more information, please contact: [email protected].