Making the Most of Wastewater Wattage

By John Franceschina

‘Ultra-Clean’ fuel cells boost digester gas solutions for distributed generation and combined heat and power (CHP) at California’s Dublin San Ramon Services District.

Wastewater treatment facilities rely on distributed generation to keep operations up and running. Anaerobic digestor gas (ADG) produced from their treatment process is an integral part of their energy mix, traditionally providing as much as 50% of electrical power at many plants. For the past 30 years, this ADG has typically been used to power turbines or combustion engines to generate both heat and electricity.

Water and Energy

Large amounts of wastewater, though, are produced where large numbers of people live, and burning ADG isn’t inherently clean, quiet or unobtrusive. Problems have been exacerbated as states and air quality management districts tighten environmental requirements, with California leading the way in introducing tough new environmental standards. How can a wastewater facility keep or even improve its ADG cost savings and renewable fuel incentives, while meeting tough new emissions standards? Ultra-clean fuel cells provide the answer, operating without combustion, generating negligible emissions, and using ADG more efficiently than any other distributed generation power source.

In the USA, the Dublin San Ramon Services District (DSRSD) in California’s Tri-Valley area is a good example of a forward-thinking facility applying the fuel cell solution. DSRSD is installing two Direct FuelCell® (DFC®) DFC300MA™ power plants, manufactured by FuelCell Energy Inc., at its Regional Wastewater Treatment Facility in Pleasanton. The city’s fuel cell power plant is the central component in efficient operation of its wastewater treatment cycle. As a byproduct, the fuel cells generate heat that’s recovered and used to heat sludge, optimizing the anaerobic digestion process that generates methane gas. The gas is then returned to the DFC to fuel the plant. Located in the heart of the city, surrounded by a residential neighborhood and community athletic fields, these fuel cells provide 600 kilowatts (kW) of electricity on a 24/7 basis, with virtually no emissions and very low noise levels.

The Pleasanton plant is one of three fuel cell power plants within just a 10-mile radius. In Livermore, California, fuel cells also are used in conjunction with wastewater treatment, while at the Santa Rita Jail in Dublin, a 1 megawatt (MW) fuel cell complements a large solar installation. Across the state, the cities of Riverside and Rialto, and the Turlock Irrigation District and Eastern Municipal Water District also are proceeding with similar power plant installations.

Free and Clear

Explosive population growth in the region has led to a recent expansion of the Pleasanton wastewater treatment plant (WWTP)’s capabilities, from 11.5 million gallons per day (MGD) to 17 MGD, or 48% more wastewater. While planning the expansion, plant managers kept their focus on additional efficiency goals important to the district and its ratepayers. These included a reduction in total energy required to treat wastewater, an increase in distributed generation capabilities and recycling of the wastewater for use in the surrounding community.

The decision to install high-efficiency aeration fans, UV disinfection lights and variable-speed pump motors all helped to reduce electrical demand. Water recycling and a new state-of-the-art sand filtration and distribution system eliminated the need to pump effluent 16 miles away to San Francisco Bay, further reducing electrical demand from the grid. Instead of being shipped out to sea, the dramatically cleaner water now provides much-needed irrigation at high schools, parks, libraries and golf courses.

In a community equally concerned with environmental impact and saving its customers money, a fuel cell system that could make the most of increased wastewater production was a perfect fit. Not only does the fuel cell power generation system produce its electricity cleanly and quietly, its increased efficiency helps to further reduce the plant’s overall operating costs and provides reliable power independent of the grid – all from an existing renewable resource.

A Green Alternative

Because fuel cells make energy through a non-combustive process, they produce virtually zero emissions of nitrogen oxides (NOx), sulfur oxides (SOx), and particulate matter (PM). Regardless of if Pleasanton is operating its fuel cells on digester gas, natural gas or any combination of the two, the plant remains classified as an “Ultra-Clean” installation under California law.

The DFC300MA is certified to meet the stringent distributed generation emissions standards established by the California Air Resources Board (CARB). Meeting this standard also exempts it from air pollution control and air quality district permitting requirements. Certification qualifies the fuel cell for preferential rate treatment by the California Public Utilities Commission (CPUC), which includes elimination of additional exit fees and standby charges. Thus, the fuel cell system demonstrated its ability to save money not only via efficient operation but also fast-track installation and rate benefits.

But the biggest payoff for the WWTP still lies ahead, as stringent new regulations take effect in California. Phased in over the next five years, South Coast Air Quality Management District (SCAQMD) Rule 1110.2 will require both new and existing plants to produce power from ADG as cleanly as they produce it from their primary power source. This requirement will likely cause a scramble at ADG-burning sites using combustion engines and turbines, particularly at older installations with less efficient equipment.

In fact, the standard may prove difficult to meet with some technologies, putting the cost advantages of using digester gas energy in jeopardy across the state. SCAQMD reports note the lack of compliance to the new rule faced by internal combustion engines, and the need for continuous or periodic monitoring of NOx, SOx and other pollutants. SCAQMD even lists fuel cells as one of the best approaches for distributed generation requirements under the new rules, and warns that buying more power from the grid (in addition to solar power) may be one of the only other options for near-zero emissions compliance. Such concerns put sites like Pleasanton ahead with a real-world solution, providing a superior method of cost-effective compliance.

Fuel Flexibility

Large stationary carbonate fuel cells like the one at Pleasanton have a history of proven results in distributed generation systems worldwide, including many WWTPs. The cleanliness and fuel-flexibility savings offered by the 300 kW DFC power plants were important decision criteria. “By installing fuel cell power plants running on biogas, we are able to help the community reduce emissions and lessen demand for power from the local grid,” says district general manager Bert Michalczyk. “And the wastewater treatment facility benefits from having onsite, reliable, 24/7 power that reduces the need for more expensive energy from the local utility. It’s a compelling proposition for the people in the Dublin San Ramon Service District.”

Ideally configured in size for such applications, the DFC300MA is a high-temperature, high-efficiency carbonate fuel cell power plant. Pleasanton installed two units for a total capacity of 600 kW of baseload power. DFC power plants can operate on biofuels – gases from food processing, landfills and wastewater treatment – in addition to natural gas, ethanol, diesel and coal gas. Pleasanton’s fuel cells use ADG, augmented with natural gas when required, to complete the hydrogen reforming process. This ability to maximize electricity production from readily available onsite fuel resources is an important advantage over other fuel cells, that may require external fuel processing to obtain a hydrogen supply.

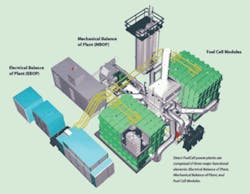

DFC power plants use a modular design containing separately configured units for power generation (i.e., fuel cell modules), Electrical Balance of Plant (EBOP) including power conditioning and grid interconnect, and Mechanical Balance of Plant (MBOP) including fuel supply and conditioning, and heat recovery (see Figure 1). Each module is arranged on its own skid to provide efficient transport to the installation site, installation flexibility, and ease of access for plant maintenance.

The MBOP incorporates a fuel and water treatment module and de-oxidizing reactors to treat the fuel. The Heat Recovery Unit/Anode Gas Oxidizer (HRU/AGO) module then takes the treated fuel and cold water and produces a heated fuel/water mixture for delivery to the fuel cell module, which consists of fuel cells arranged into stacks that produce DC power. The EBOP converts DC power to AC for use with the existing utility grid. This module contains the inverter, control system, operator interface, transformers, and all grid interconnection hardware.

Additional Advantages

In addition to its green credentials, distributed generation with fuel cells has two primary advantages over systems relying on microturbines or reciprocating engines: a) an ability to generate more high value electricity, and b) significantly lower noise levels that help maximize siting flexibility and reduce disruption of community life.

DFC power plants convert ADG into electricity more efficiently than any other distributed generation technology, making the most of a valuable resource. Moreover, adding heat recovery to the electrical conversion efficiency results in an overall operating efficiency of over 70%. Such synergies make fuel cell power plants the most logical, clean and cost-effective choice for wastewater treatment applications.

Waste heat has obvious benefits in a WWTP producing ADG. But as valuable as the waste heat is, it’s no match for the cost of electricity required to run the plant. Electricity produced during cogeneration has a value 10 times as high as the associated waste heat, a fact underscored by recent price surges for grid-supplied electricity. Therefore, reducing electrical power purchased from the grid can save significantly more money than generating larger quantities of heat for a given application.

Cogeneration with a fuel cell, especially one using ADG, helps shift the power paradigm when considering those tradeoffs. Traditional cogeneration installations using microturbines or reciprocating engines typically focus on putting their copious waste heat to good use. While this approach makes efficient use of waste heat, it also can mask the lower overall efficiency of the motor-driven system when compared to a fuel cell system. For example, with an electric power generation efficiency of about 20%, a microturbine would provide a 1:3 ratio of electricity to waste heat. A reciprocating engine operating at about 33% electric power generation efficiency yields a 1:2 electricity-to-heat ratio. Generating less electricity from the system means buying more electricity from the grid – and at higher prices.

In contrast, Pleasanton’s fuel cell system, with an overall electrical power generation efficiency of 47%, provides two units of electricity for each unit of waste heat. While still capturing waste heat from its own operating process, it creates significantly more high-value electricity that doesn’t need to be purchased from the grid. This advantage means significantly higher dollar savings, particularly during periods of peak electrical demand.

Fuel cells also provide significant reductions in ambient noise compared to a motor-driven or boiler-fired system, creating an unobtrusive power source for a quieter environment and reduced impact on the surrounding area. A 300 kW fuel cell produces a noise level of 72 decibels (dB) at just 10 feet of distance, and an optional modification can reduce this to 65 dB, within the range of normal human conversation. By contrast, a typical micro-turbine system, producing just 60 kW, is rated at 70 dB at 10 meters, or 33 feet distant. And a 60 kW diesel generator is louder still, producing 100 dB at seven meters. Thus, the fuel cell can provide five times the electrical power, sited up to three times closer to where that power is needed. In Pleasanton, the fuel cells help keep the neighborhood quiet, and the neighbors happy.

Renewable Power

With demand for alternative energy solutions growing across California, the USA and world, many facilities are looking to add additional renewable power systems, including large solar installations. For many, it’s mandated. Before committing to such investments, wastewater treatment facilities – especially those with ADG generation – might want to take a second look in their own backyards.

With a conversion efficiency 30% higher than microturbines or reciprocating motors, a carbonate fuel cell offers an immediate increase in electrical production from an existing resource. This type of investment may replace older motors, but doesn’t require extensive rework for plumbing, wiring and other installation. And rather than increasing the space required for such items as solar arrays, a fuel cell is smaller, less visible and can be put virtually anywhere within an existing facility.

And, as any plant manager knows, power consumption doesn’t necessarily synchronize with the sun’s output, and overall peak electrical demand may typically occur between 7 p.m. and 10 p.m. Although it may be a lot less attractive a resource than sunshine, wastewater (and the ADG produced from it) is available 24 hours a day.

Pleasanton’s treatment of wastewater is the most obvious benefit they provide to their valley neighbors, but their distributed generation capability is certainly a close second. By producing much of its own power, the city allows the power grid to operate in a less congested and thus more efficient manner. Benefits of this type came into clear focus again during August and September 2007, when scorching heat across California strained the state’s electrical grid and left hundreds of thousands of residents without power. This was eerily reminiscent of summer 2006, when another California heatwave left millions without electricity during record-setting temperatures. With more residents moving into the Tri-Valley area, the result of such weather events could move from merely unsettling to literally life threatening.

More recent events involved a surplus of not sunshine, but snow, from dustings in Los Angeles to 10 feet in the surrounding Sierra Mountains. Rather than representing an added strain on the system during such incidents, fuel cell power plants can continue to operate efficiently, reducing demand from the grid and contributing to a solution instead of a problem. And as the valley’s residents turn off other essentials to survive power drops, they can take comfort in the fact their wastewater treatment, of all things, will happily remain functional in a crisis.

Author’s Note:

John Franceschina is Vice President of Business Development for FuelCell Energy, based in Danbury, Connecticut, USA. Contact: 203-825-6000, [email protected] or www.fuelcellenergy.com