BIG Breakthroughs - Drinking water innovations that aim to quench the world's thirst

Access to safe drinking water is a global crisis, which is why developing new, innovative ways to convert river water, wastewater and agricultural waste into clean water is critical. Thanks to new innovations in the field of treatment, promising technologies could eliminate the reality of living with scarce water resources. Here are a few of the most interesting innovations we’ve seen enter the clean water space over the last year.

From Dirty to Clean in Just One Step

Think you can’t get clean, drinking-water-quality water from sewage in just one step? Think again. Pro Equipment Inc.’s CORNCOB II is a high-pressure, high-velocity-cross-flow ultrafiltration disc membrane system. The system includes new technology intended to eliminate conventional pretreatment, increase the throughput flux (gpd/ft2) to new levels, and reduce operating energy.

The dynamic membrane system is comprised of 1’-3’ membrane discs, stacked vertically, then housed in a pressure-enclosed cartridge. Contrary to traditional membrane filtration, which spins dirty water around a membrane to move water through the filtration process, the discs themselves are spun to filter out even large solids. The name comes from the way the device looks: a meshed rotating disc system with discs mounted on two or more adjacent shafts where the discs on one shaft fill the space between discs on the adjacent shaft - like a corn cob. The shafts create optimal rotational speed, resulting in high-velocity cross flow for continuous self-cleaning action.

“Traditional treatment requires 8-10 steps to end up with ‘clean’ water, usually just to environmental discharge standards,” Douglas Hwang, president and co-inventor of CORNCOB, said. “The CORNCOB Dynamic Membrane Technology has the capability to take not only typical water sources but inferior sources and turn it into potable quality, in one step. It’s as easy as in and out.”

The company has been traveling the U.S. with its mobile pilot unit since October 2016, demonstrating the technology at 15 projects nationwide. The technology has successfully treated municipal wastewater, landfill leachate, fracking water, and agricultural wastewater, with impressive results.

Drops of Sunlight

To disinfect dirty water using a water bottle under direct sunlight, you might have to wait about two days because UV rays carry only 4 percent of the sun’s total energy. Now, with a breakthrough from researchers at the Department of Energy’s SLAC National Accelerator Laboratory and Stanford University, clean water might be closer than you think.

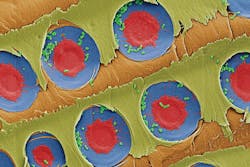

A small device (about half the size of a postage stamp) claims to harness more energy from the sun to form hydrogen peroxide and other disinfecting chemicals. In just 20 minutes, more than 99.999 percent of bacteria was eliminated from a sample.

Thin flakes of molybdenum disulfide (an industrial lubricant) arranged like walls on a glass surface and topped with a thin layer of copper react with sunlight to form “reactive oxygen species” that kill bacteria, according to a report published in Nature Nanotechnology. These reactive oxygen species include hydrogen peroxide, a commonly used disinfectant, which kills bacteria in the surrounding water.

“We just dropped [the device] into the water and put everything under the sun, and the sun did all the work,” said Chong Liu, lead author of the report, in a statement.

While the device has only been tested on three strains of bacteria mixed with less than an ounce of water in the lab, the results are promising for many in the developing world who could use this device to disinfect water on the go.

Barking up the Right Tree

A team of researchers at MIT found that peeling the bark off of a pine tree branch would produce a low-cost water filter that can remove impurities in up to 4 liters of water per day. Mechanical engineering professor and study co-author Rohit Karnik showed that even a small piece of sapwood was able to remove more than 99 percent of bacteria like E.coli from a sample. Using a piece of white pine cut to about an inch long and one and half inches wide, each piece of wood was then placed inside plastic tubing and secured with clamps before the “dirty” water passed through the system. In a few experiments, the study found that particles larger than 70 nanometers were contained inside the wood, allowing clean water to pass through to the other side.

Karnik told MIT News, “We don’t need to fabricate a membrane because it’s easily available. You can just take a piece of wood and make a filter out of it.”

The simplicity of this treatment lies in the details, which researchers say mimic challenges faced in the water treatment industry. The wood, made up of xylem tissue, is designed to transport sap in the tree’s system. The xylem is also designed to remove air bubbles in the sap without disrupting the flow rate. Tiny pores present in the wood allow the sap to flow throughout the length of the tree, while trapping air bubbles along the way and leaving pure sap in the system. When water runs through the bark, the flow traps bacteria inside the bark’s xylem tissue, allowing clean, fresh water to come out the other end.

Be Still My Heart, Times Two

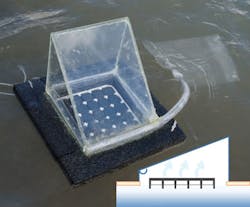

Solar stills are not new technology, having been around for thousands of years. The basic design includes a dark-bottomed water vessel that absorbs sunlight and increases evaporation rates for the water inside. Then, a clear material placed on top captures the water vapor, and the condensate flows into a separate collection vessel. The process can be time consuming and does not easily scale up to collect large volumes of clean water for easy use. But groups at two universities are looking at ways to improve the process.

At the State University of New York (SUNY), researchers have achieved an 88 percent success rate with their low-cost still. They first use a fibrous paper coated with carbon black, a material produced by the incomplete combustion of tar or coal. Next, they take a block of polystyrene foam, cut into 25 sections to be used as a float for the still. Pieces of the carbon black-coated paper are then layered over each section of the float, allowing the ends to dip into the water below and act as a wick so that each of the sections on the float gets wet. An acrylic housing sits on top of the device, capturing the evaporate from the pool of water below.

A 1-square-meter device has been shown to purify up to 1 liter of water an hour, and the low cost of the materials used means that a family of four could build a device suitable for treating all the water they need for about $5. The technology is especially suitable for areas without reliable access to electricity, as sunlight is the only source of energy required for production. The SUNY researchers have formed a company to scale up commercial production and bring the still to market.

Another low-cost still comes from MIT and researchers led by mechanical engineer Gang Chen. Years in the making, the still’s secret ingredient is bubble wrap. A thin layer of material used in commercial water heaters is used to absorb sunlight. Placed on top of a thin sheet of copper atop a layer of foam (to make the still float), researchers poked holes through the layers to allow the water to evaporate into the bubble wrap insulating layer. To be used in drinking water applications, an additional glass layer would need to be added to collect the water vapors, but preliminary findings are promising, and could allow large-scale production to be completed for about one-twentieth of conventional costs for similar technology.

What Now?

These are just some of the innovative technologies poised to change the face of water treatment in the coming years, with many more on the horizon. Fueling the development of these technologies are people with a passion and drive to solve the world’s water crises.

Alanna Maya is the assistant editor for WaterWorld and Industrial WaterWorld. Email her at [email protected].

About the Author

Alanna Maya

Chief Editor

Alanna Maya is a San Diego State University graduate with more than 15 years of experience writing and editing for national publications. She was Chief Editor for WaterWorld magazine, overseeing editorial, web and video content for the flagship publication of Endeavor's Water Group. In addition, she was responsible for Stormwater magazine and the StormCon conference.