Say No to Crack (Injection)

Georgia water treatment plant eliminates costly crack-filling process with self-healing concrete admixture

By Hank Giles

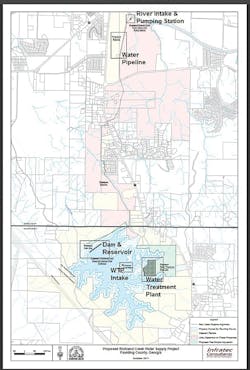

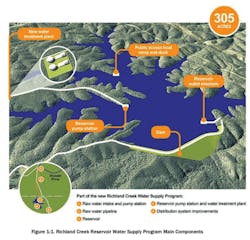

Paulding County is one of the only counties in the metro Atlanta region without an independent water supply and has long relied on the Cobb County-Marietta Water Authority (CCMWA) to supply its water. With Paulding County’s population projected to double over the next 25 years, an abundant, secure, and independent supply of water is needed to support a healthy, thriving community.To solve this challenge, Paulding County voted in 1999 to begin the largest public works program ever undertaken by the county. After significant efforts involving numerous federal and state governmental agencies, including the U.S. Army Corps of Engineers, the County was granted a 404 permit in October 2015, allowing the construction of the $215 million Richland Creek Reservoir Water Supply Program.

Water Freedom

The water supply project, scheduled to go on-line in the fall of 2019, features the construction of a new 305-acre reservoir fed by a 3.7-mile-long, 48-inch steel pipeline that draws water from the Etowah River to the north. The new water treatment plant (WTP) will draw raw water from the new reservoir and produce drinking water for 47,000 customers at a rate of 18 million gallons per day (mgd), expandable to 36 mgd.Critical elements in the water supply program included the 2,965-foot-long earthen dam, a concrete river intake and pump station, raw water pipeline to the reservoir, drinking water distribution system improvements, and WTP with reservoir intake and pumping station.

Burlington, Vt.-based PC Construction built the water treatment plant as well as other elements of the project. Xypex Admix C-500 crystalline waterproofing was used in all the water-holding structures in the WTP, so PC Construction was able to achieve leak-free concrete without any additional cost.“We didn’t have to spend any time or money on crack injection on the Richland Creek project,” said Dan Nawrocki, vice president for PC Construction. Epoxy injection is a common means to seal shrinkage cracks that appear in new concrete. The process is time consuming and costly. “By using Xypex Admix in the concrete for all the water-holding structures, the leaks we experienced healed themselves,” he said.

Paulding County officials collaborated with program manager Brown and Caldwell and the design firm Arcadis. Three construction companies took responsibility for the main parts of the program — Brad Cole Construction built the reservoir; Garney Construction/Croy Engineering provided design-build services for the raw water pipeline; and PC Construction was the construction manager at risk (CMAR) for the WTP as well as intake pumping stations on the Etowah River and in the reservoir.Xypex in the Design

Arcadis, based in the Netherlands, is a global design, engineering and management consulting firm with offices in 40 countries. The design firm was already familiar with the benefits of Xypex crystalline waterproofing technology, having used it recently in a wastewater project for the city of Birmingham, Ala.

“Arcadis recognized the value Xypex delivers and decided to use it for the Richland Creek project,” noted Paul Derby, a Xypex technical consultant for the southeast U.S. region. “The addition of [the admixture] to the concrete used in the water-holding structures at the water treatment plant means that other waterproofing and protection coatings could be eliminated from the design, saving time and money.”The design firm specified that Xypex Admix be added to the ready-mix concrete at a dosage rate of 3 percent by weight of cement.

“[It] is typically used at 2-3 percent by weight of cement in the mix,” Derby said. “Arcadis wanted the higher dosage rate to ensure maximum protection against some of the chemicals that would be used in the water treatment process and to protect the concrete and the reinforcing steel within it.”

Benefits Built In

The admixture is added to concrete at the time of batching and consists of Portland cement, silica sand, and various active, proprietary chemicals that react with the moisture and the by-products of cement hydration to cause a catalytic reaction that results in the formation of non-soluble crystals that fill the natural pores and capillary tracts in concrete. This crystalline formation prevents the penetration of water and other liquids from any direction.The waterproofing technology becomes a permanent and integral part of the concrete structure and continues to work to prevent the ingress of water and other liquids for the life of the structure. It not only permanently seals the concrete and can heal hairline cracks up to 0.4 mm, it also provides chemical resistance properties that mitigate the attack of chlorides, sulfates and the effects of carbonation and alkali-aggregate reaction.

The admixture was added by the ready-mix firm for the project — Tallapoosa, Ga.-based Wayne Davis Concrete — during the dry batching process at its Rockmart and Hiram plants. About 6,000 cubic yards of the 50,000 total cubic yards of concrete used throughout the project were treated with Xypex Admix. Key parts of the WTP, including the chemical storage and mixing building, dissolved air flotation (DAF) and filtration building, granular activated carbon (GAC) storage and filtration, gravity thickener tank and apparatus, and clear well splitter box were poured with the treated concrete to ensure watertight structures and protect against the harmful effects of certain water treatment chemicals.The treatment plant will utilize DAF equipment, gravity thickening, sand filters and GAC filters to treat the water. The finished water will then flow into a 6.3-million-gallon clear well for storage. Once the treatment process is complete, water will be pumped from the clear well to end users through a new water transmission line.

PC Construction project manager Joe DeHart, who oversaw construction of the WTP and two intake pumping stations, had little prior experience in using Xypex, particularly as an admixture. “I wouldn’t say I was skeptical, but my expectation was that it would reduce the incidence of early stage cracking and reduce our need for crack injection to seal leakage. I never thought it could be a total solution,” he said. “It is a rare case when you pour a large water holding structure and you don’t have any leaks. When leaks do occur, you end up crack-chasing with an injectable product that, depending on how serious the cracks are, takes time and can become costly.”Successful First Test

At the Richland Creek WTP, one of the first structures poured was the 40-foot-diameter gravity thickener tank, which is used to condense the volume of residual solids. Approximately 200 cubic yards of ready-mix concrete treated with the waterproofing technology was used to pour the tank.

In April 2017, the newly poured tank was filled with about 12,000 gallons of clean water in order to leak test it. Within a few days, seepage was seen on the outside of the tank from several thin cracks of varying heights. On most jobs, PC Construction would have immediately called for a crew to come on site and begin the crack-filling process, which requires the crack to be cleaned, with surfaces sealed, injection ports installed, epoxy or grout injected, and clean-up and refinishing. Once cracks have been sealed the tank would have to be refilled and leak tested again.At Richland Creek, because the concrete was treated with the admixture, the tank could continue leaking in order to enable the active chemicals in Xypex to react with the moisture and the by-products of cement hydration to enable the catalytic reaction to generate non-soluble crystals that gradually sealed the leaks in the gravity tank.

Investment Value

PC Construction’s Dan Nawrocki was particularly impressed with the results. “Concrete cracking is very unpredictable. Sure, Xypex costs a little more up front, but it is an investment in quality. The protection [it provides] is built into the structure and continues protecting [it] throughout its lifespan.”DeHart said that the waterproofing technology could play a growing role in future projects. “As we do more and more design-build and CMAR projects, we have opportunities to specify Xypex during the design process,” he said. “Those are situations where we can help the owner realize a better final product with long-term benefits while eliminating uncertainty.” WW

About the Author: Hank Giles is a freelance writer based near Boston, Mass. He has more than 20 years of experience covering construction, concrete production, business management, property insurance, engineering and information technology.