Multiphase Flow Simulation Guides Wastewater Treatment Plant Design

Computational fluid dynamics simulation minimizes construction costs

while maximizing health of Eindhoven Wastewater Treatment Plant

By Sarah Fields

The humble Dommel River flows through the city of Eindhoven, the Netherlands, from the Belgian border in the south into the larger Maas River in the north. Along the way, it receives discharges from the Eindhoven Wastewater Treatment Plant (WWTP) as well as over 200 combined sewer overflows (CSOs) from 10 municipalities, handling approximately 170,000 cubic meters of water per day.

The Dommel Water Board is tasked with overseeing the health of the river and achieving the best possible balance between people, the environment, and the economy. To do so, the board launched KALLISTO, a comprehensive research project that aims to find the most cost-effective set of measures to minimize oxygen dips and ammonia spikes caused by the combination of biologically treated WWTP effluent and CSOs. Addressing these goals allows the board to meet the Water Framework Directive and support the ecosystem of the Dommel.

“Limits for phosphate, nitrogen, and suspended solids in the Dommel River have been and will be further reduced to maximize the health of the river,” explained Tony Flameling, senior advisor in water technology at the Dommel Water Board.

Aerial view of the Eindhoven Wastewater Treatment Plant.

As part of this effort, the Water Board introduced an aeration system to further increase the oxygen level of the biologically treated wastewater effluent before it merges with the river. “The purpose of adding this aeration system was to protect the ecosystem of the Dommel from the damaging effects of hypoxia,” Flameling explained.

At the wastewater treatment plant, before aeration, nutrients and solids are removed in pre-sedimentation, activated sludge, and clarifying processes. To minimize energy requirements, water is maintained at a height that keeps the water moving throughout the plant.

To understand how adding aeration would affect the flow, Flameling conferred with Ronnie Berg, a consultant with Tauw specializing in process technology and water management.

“If the water height in an effluent channel is too low, the oxygen transfer is ineffective. On the other hand, if the water height is too high, then there exists the unpleasant possibility of overflow from the aeration channel back into the clarifier, contaminating the outflow,” Berg explained.

Another potential problem is water height that is too low for the water treatment processes to be operative. Knowing the flow profile in the effluent channel and associated outflow channel, the Water Board could determine how best to optimize the system for maximum aeration.

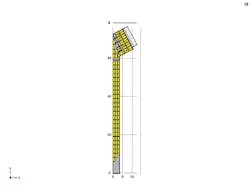

Schematic of the water treatment stages of the Eindhoven Wastewater Treatment Plant (WWTP). Aeration is introduced after the clarification, immediately before the reintroduction of the treated water to the Dommel River.

Bubbles: Good for Fish,

Bad for Flow?

To fully understand the influence of aeration and dams on the flow profile and water levels, Berg turned to multiphase flow simulation using the COMSOL Multiphysics® software.

Knowing that an existing channel would be retrofitted for aeration, Berg created the geometry of the effluent channel, including walls, existing guide baffles, and planned locations of the aeration elements.

To characterize the system, Berg played with the arrangement of the aeration units, the heights of different sections of the adjustable dam, and the water level of the Dommel. In this way, he could determine whether there was a benefit to keeping the existing guide baffles in place as well as how the flow profile would change depending on aeration, season, and water level of the Dommel.

View of the adjustable dam at the outlet of the aeration channel.

Berg set up the fluid flow model considering a highly turbulent regime and dispersed bubbles. Using the bubbly flow, k-epsilon interface available in the software, Berg was able to capture the effect of aeration on the flow profile. By modeling the bubble-induced turbulence and tracking the effective gas density, he was able to analyze the additional resistance created by the bubbles and the induced spiral flow in the channel.

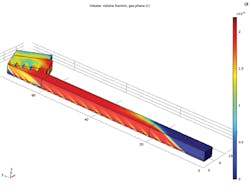

In a set of computational fluid dynamics (CFD) simulations, Berg explored the effect of the Dommel’s water level on the flow profile. He was also able to determine the volume fraction of gas at any location throughout the channel, making it possible to understand the effectiveness of the aeration system.

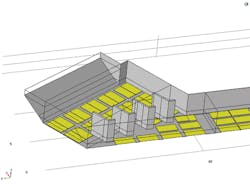

Geometry of the aeration channel. Aeration units are represented in yellow.

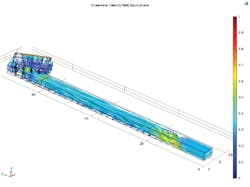

Berg also evaluated the performance of the virtual aeration unit in dry weather when the water level of the Dommel River is low. In the case of a low flow rate, all of the sections of the adjustable dam are in place, leading to some backflow.

Berg’s analysis of the flow profile, with varying water levels, dam heights, and aeration, ultimately led him to several findings. He learned that in the case of high effluent flow rates, aeration has little influence on the flow profile. In the case of dry weather, the aeration does affect the flow profile. The resistance created by the aeration is relatively low, leading to a low risk of water flowing back into the clarifier and contaminating the outflow.

The aeration channel of the Eindhoven Wastewater Treatment Plant in full operation as it improves the oxygen quality of the effluent before reentering the Dommel. Left: View of the adjustable dam at the outlet of the aeration channel. Right: View of the aeration channel from the inlet.

Berg also investigated the effect of activating two out of the three sections of the adjustable dam. When using only two sections, the flow was significantly higher in the outside bend. This resulted in stagnant water near the inside bend and a less efficient aeration process. Overall, the best flow profile was obtained when activating all three sections.

CFD simulation results showing the volume fraction of the gas phase in the case of a high water level of the Dommel.

Simulation Informs the Design Process

Based on his comprehensive CFD analysis, Berg made recommendations to the Dommel Water Board, advising not to remove the guide baffles. He also recommended placing the upstream aeration elements in a linear configuration in order to minimize the construction costs while satisfying water quality requirements.

“Simulation enabled us to adjust the parameters in a controlled way and gave us the flexibility to find the best design before construction,” said Berg. “This ultimately enhances the quality of the water leaving the Eindhoven Wastewater Treatment Plant in a cost-efficient way.

CFD simulation results showing the velocity field of the treated water through the aeration system in the case of dry weather.

Flameling added that the intended effect of the aeration system is now being observed, to the benefit of the river’s ecosystem. The efficiently designed aeration unit will support the ecosystem and the people who rely on the Dommel River for years to come.

About the Author: Sarah Fields is a marketing engineer at COMSOL with a focus on writing and producing articles and presentations about the COMSOL Multiphysics® software. She holds an MS in chemical engineering from the University of Rhode Island.

Circle No. 251 on Reader Service Card