Reducing Bromate Formation Through Sidestream Ozone Injection

By Jim Jackson

The design of a utility’s ozone disinfection system often includes a method to minimize the production of regulated oxidation by-products that may form when ozone contacts the water. In regions where water contains a significant concentration of bromide ion (Br -), ozone disinfection systems often minimize bromate (BrO3-) formation by modifying the water chemistry through the addition of chloramines, acid, or other chemical additives.

Bromate reduction that is provided by changing the method of ozone dissolution is an engineered solution that promises to minimize and, in some instances, eliminate the need for chemical addition at municipal ozone installations utilizing a water source containing an elevated concentration of bromide ion. The preliminary results from Water Research Foundation project 4588, recently published by the Southern Nevada Water Authority, suggest that changing the ozone dissolution method from fine bubble diffusion (FBD) to sidestream Venturi gas injection can reduce the formation of bromate without the need for chemical addition.

Process engineers have always recognized that the ozone contacting system design can affect the rate of bromate production. Some have adopted the belief that sidestream injection (SSI) generates higher concentrations of bromate than FBD, based solely on the high ozone dosage applied to a sidestream Venturi injector. Recent testing of full-scale and pilot SSI systems, however, has indicated that excess bromate production by SSI is not a given, in spite of the high applied ozone dosage at the Venturi injector.

Sidestream Injection and Bromate Formation: Full Scale Data

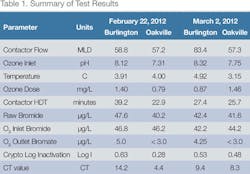

The belief in increased bromate formation from SSI was challenged when the Regional Municipality of Halton in southern Ontario began reporting low bromate concentrations at its plant that utilized SSI, the Oakville Water Purification Plant. In a 2012 paper, “Bromate Formation Differences between Ozone Side-Stream-with-Degas and Diffuser Transfer Systems,” full-scale data from the Burlington FBD plant and Oakville SSI plant indicated that SSI consistently produced lower bromate concentrations than FBD (see Table 1).

Sidestream Injection and Bromate Formation: Pilot Study

Halton’s testing of bromate formation at its water purification plants led to a formal study by the Southern Nevada Water Authority (SNWA) in Las Vegas, Nev. The research, initially funded by the Region of Halton, ultimately became Water Research Foundation (WRF) project 4588.

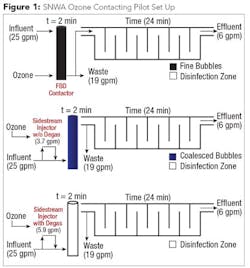

SNWA examined bromate formation by piloting three different ozone contacting methods: SSI with degas, SSI without degas and an FBD column contactor. Raw water from Lake Mead was pumped through the pilot ozone contactors’ ozone dissolution zones at a flow rate of 25 gpm. Of this, 19 gpm was wasted, with the remaining 6 gpm directed to smaller contact columns for ozone reaction. Each column was sized to provide two minutes of contact time.

For the FBD tests, ozone gas produced by an oxygen-fed ozone generator was directed into FBD stones installed at the bottom of a 12-foot-tall column contactor. For the SSI tests, ozone gas was directed into either SSI with degas or SSI without degas ozone dissolution systems (see Figure 1).

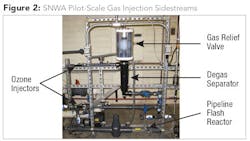

The two SSI systems were designed to mimic full-scale plant installations. During testing of SSI, a portion of the 25 gpm mainstream flow was directed through the top injector-degas separator contact train or through the lower injector contact train. The effluent from either SSI train was blended back into the mainstream flow at the pipeline flash reactor (PFR), a secondary gas mixing device that provided efficient mixing and transfer of the SSI ozone into the bulk water flow (see Figure 2).

Pilot Test Results & Discussion

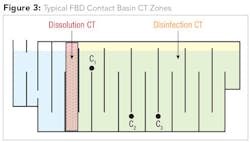

The reason for excess bromate formation by FBD became apparent during sampling for ozone residual along the vertical length of the 12-foot diffusion column. Analysis of water samples taken at 1-foot intervals showed that ozone residual developed early within the FBD dissolution column, resulting in sufficient dissolved ozone contact time to provide a “CT” (ozone concentration [C] x minutes of hydraulic detention time [T] in FBD column) that produced bromate ion. However, it is important to note that the “Dissolution CT” in the contacting column of the FBD cannot be claimed as CT in the calculation of the plant’s “Disinfection CT” credit (see Figure 3).

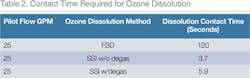

In an FBD contact basin, contact time for ozone dissolution is relatively large and results in a fairly high value for Dissolution CT. The FBD Dissolution CT that forms bromate, but is unclaimed for disinfection CT, is “high” at a water plant’s design flow, and even higher at turndown water flow, potentially leading to an increased bromate formation during periods of minimum water flow. Conversely, in SSI designs the contact time required for ozone dissolution is limited (see Table 2) and is consistent even during turndown. In addition, any bromate formed in the sidestream flow is significantly diluted when it is mixed with the mainstream flow.

Continuing Research/Potential SSI Benefits

Research by SNWA under WRF project 4588 is ongoing, with final results to be published in 2017. Pilot test data continue to support the concept of Dissolution CT as a mechanism to explain the bromate production differential in the FBD and SSI ozone contact systems. Project test results published by SNWA indicate that removing the gas dissolution zone from an ozone contactor by installing a pre-basin SSI-PFR ozone dissolution system may prove to be a useful method to reduce or eliminate the need for chemical addition by ozone drinking water plants that are struggling to comply with the regulatory bromate MCL of 10 μg/L.

About the Author: Jim Jackson is the director of municipal sales at the Mazzei Injector Company. He is the author of numerous papers and articles on industrial and municipal ozone applications and a longtime member of the IOA, AWWA, WEF and other water and wastewater organizations. Jim has a Bachelor of Science in Biology and has spent over three decades as a water treatment professional, with a primary focus on ozone applications since 1995.