Water Connections: Stormwater Collection and Treatment for Re-use

The collection and treatment of stormwater for reuse is a growing market that enables collected stormwater to be used for a variety of applications including irrigation, non-potable applications (toilet flush water), process water or cooling tower feedwater (industrial), and occasionally even for potable water.

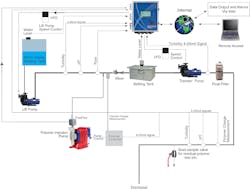

The W900 controller is designed for use in OEM systems that capture, measure, control, and deliver harvested rainwater, treated as necessary for the intended use, and enables complete system control from the simplest to more sophisticated systems. Its data log of system parameters enables the user to monitor the amount of water processed so that ROI savings can be calculated.

The most popular use for harvested stormwater is for irrigation, which accounts for approximately 34 percent of all water use in the U.S. Collected stormwater quality varies depending on the source (rooftops, stormwater culverts, etc.). Some collected water can be simple to treat while some may require a controller for correction of water quality parameters such as pH, suspended solids and disinfection. The water quality can usually be determined by simple tests.

Another common application for harvested stormwater is for toilet flush water, which has become popular with schools and other small institutional facilities. A dye will normally be injected into the collected water to differentiate it from potable water. These systems can be more complex if there is a tie in with city water systems, but there are many OEM system manufacturers who specialize in these systems and have made some standard designs very affordable.

Control for a stormwater harvesting system may include data collected from flow meters, level sensors, and water quality measurements, which may include pH, conductivity, temperature, streaming current, ORP and/or turbidity, depending upon the planned use for the collected, treated water as well as the treatment process.

The W900 controller interfaces directly with the analytical sensors so that calibration and other diagnostic information can be evaluated. The analytical measurements can provide important data such as pH to insure the water will not cause corrosion or scaling in the piping systems, conductivity to monitor the total dissolved solids (TDS) in the water, turbidity to monitor the total suspended solids (TSS), and ORP (oxidation-reduction potential) if an oxidizing disinfectant (such as chlorine) is used. Temperature is important if the water is being used for a cooling process, and streaming current is a measurement for determining polymer concentration, which aids in the settling or precipitation of suspended solids.

Rainwater harvesting is rapidly becoming important to institutions and industrial plants for reducing the amount and cost of purchased treated water. As more builders move toward green building practices, rainwater harvesting will become standard operating procedure. The number of OEM’s building these systems is increasing steadily, and the Walchem W900 controller provides an excellent choice for their control. WW

Iwaki America is exhibiting at WEFTEC.19, booth 4660. To learn more, visit www.walchem.com.