True Total Phosphorus with Online Colorimetric Analysis

By Howard Breder, Mark Schwind, Jay Mershon and Chris Garaffa

As total phosphorus and other nutrient limits are driven lower, managers of wastewater treatment plants (WWTP) are struggling to operate within permitted limits while also trying to control operational costs. One significant cost is excessive flocculant dosing used for phosphorus removal.

Many factors impact total phosphorus load and removal efficiency, making it necessary, especially during the warmer months of the year, to run frequent grab-sample tests to ensure compliance. In addition to biological removal, many plants are dosing flocculant for phosphorus removal. But, flocculant is frequently overdosed to avoid exceeding discharge limits, leading to a significant increase in operating costs. The time and expense of frequent grab-sample testing make optimizing flocculant dosing nearly unachievable and very frustrating because process phosphorus levels can be hard to predict.

To help address this issue, Endress+Hauser developed the Liquiline System CA80TP Total Phosphorus analyzer, a member of the Liquiline System CA80 platform of analyzers.

Prior to the release of Endress+Hauser’s Liquiline System CA80 colorimeter platform, colorimeters required frequent operator intervention and inspection to avoid costly and time-consuming instrument failures. When maintenance-intensive analyzers are complicated, the devices are all too often abandoned altogether. In the case of total phosphorus removal applications, this results in plants choosing to base polyaluminum chloride (PAC) dosing on flow and grab-sample results. The consequences are the labor time to take and analyze grab samples; the additional cost of lab testing; the increased cost of PAC to ensure compliance as process conditions change between grab samples; and an increase in sludge production. All these factors add up to significant, unnecessary operating expenses/costs.

Mountain View Wastewater Treatment Facility.

Case Example: Township of Wayne, N.J.

The Township of Wayne’s Division of Water and Sewer operates and maintains the drinking water and sanitary sewer systems throughout the township to provide residents with clean drinking water and sanitary facilities. The Division’s 13.5-million-gallon-per-day Mountain View Wastewater Treatment Facility treats all sanitary wastes and includes primary settling tanks, equalization basins, aeration tanks, final settling tanks, chlorination/dechlorination facilities, sludge pumping and storage, and sludge truck loading facilities for off-site disposal. The plant has a complete laboratory for testing and monitoring the treatment process.

During the warmer months, the township must maintain its total phosphorus discharge to less than 0.76 mg/L. After trying several orthophosphate analyzers with varying results, and often little or no correlation with lab total phosphorus results, the plant nearly gave up on online monitoring altogether. Conventional orthophosphate analyzers use ultrafiltration to filter the sample and do not digest the bound phosphorus, leading to poor correlation with lab total phosphorus tests. They also found that the orthophosphate analyzers tested required frequent inspection and maintenance to detect and correct analyzer malfunctions such as plugged sample tubing and low reagents.

Challenge

The Township of Wayne, like all municipal wastewater plants, has regulations, standards, permits and budgets it must adhere to, including regulations regarding total phosphorus levels. In the fall of 2017, the regulations, especially for total phosphorus, grew even more stringent for the township. While biological treatment is an option for total phosphorus removal, this method alone was not practical due to increased nitrate levels and the physical limitations of the facility. PAC dosing was the only practical way to comply with the low total phosphorus limit. Optimizing the process is difficult without near real-time data, and overfeeding PAC to stay in compliance as process conditions change was costly.

“Our normal phosphorus discharge runs 2.5 to 3 mg/L at peak turnover,” said Howard Breder, laboratory manager for the Township of Wayne. “In October, our phosphorus level was 3.1 mg/L. New regulations and permit limits that have been enforced now require our phosphorus discharge to be 0.76 mg/L or lower. This is extremely low for us, given the way we are running the plant today.”

The municipality was using biological phosphorus that resulted in 50 percent removal. This approach was insufficient to meet the new and more stringent total phosphorus limit. Additionally, the biological removal process increases nitrate, which is another strictly regulated nutrient. Given these challenges, the municipality made the decision to switch to chemical removal using PAC.

Breder added, “Using chemicals becomes more expensive, but if we kept biologically removing phosphorus out of the wastewater we would have had to expand the plant to be able to hit the new limit of <0.76 mg/L. We would need more tankage and the expansion would cost millions of dollars.”

Realization

The Township of Wayne tried multiple analyzers and experienced serious challenges with each instrument making it impossible to get away from frequent grab sampling. In addition to the challenge of meeting a strict limit of <0.76 mg/L, the municipality experienced a lack of accuracy, poor reliability and insufficient lab correlation with the analyzers they tested. The municipality knew it needed a more accurate and dependable total phosphorus analyzer that would provide reliable analysis with close agreement to laboratory results in near real time.

“We were looking for an analyzer that would be able to provide accurate data and wouldn’t break down every week,” said Mark Schwind, superintendent of operations. “We have limited time to manually maintain it. The analyzer we were using was providing us data, but when something went wrong with the analyzer, we had no warning.”

“The previous analyzer would continue to run when it was clogged and produce inaccurate data and it messed up the entire sampling process,” Breder said. “The analyzer kept adding chemicals without a current process sample and we didn’t know that we were overdosing chemicals, which was a large expense.”

Schwind and Breder would come in to work in the morning and check the data from the old analyzer and the numbers would seem miscalculated. The two would have to perform their own calibrations weekly if the numbers weren’t correct and make the necessary adjustments.

“We are dealing with wastewater — there are solids when it comes through the system and a lot of times it gets clogged. The weak point in all the analyzers we have tested so far is getting the sample in the machine for measurement,” said Schwind.

Endress+Hauser CA80TP Total Phosphorus analyzer.

Solution

Endress+Hauser representatives met with the Township of Wayne to demonstrate the Liquiline System CA80TP Total Phosphorus analyzer.

The municipality had tested multiple orthophosphate analyzers with poor results and had originally intended to try Endress+Hauser’s Liquiline System CA80PH Orthophosphate analyzer. However, the plant’s main goal had always been to find an analyzer that would agree with lab total phosphorus data. After being introduced to Endress+Hauser’s new total phosphorus technology, Breder and Schwind decided they would try it.

The Township of Wayne opted to purchase and install the analyzer based in part on assurances that the system would provide results consistent with the lab method.

“The Liquiline System CA80TP was easy to install compared to some of the other analyzers we tested,” said Breder. “The samples are taken automatically every 45 minutes and because of the unique Y strainer sampling approach, large solids are automatically filtered out and doesn’t result in the clogging challenges we were experiencing prior.” (See Fig. 1.)

Figure 1. Y Strainer provides “inertial filtration” of

larger solids while allowing a representative process sample to enter the analyzer.

The Y strainer provides inertial filtration by allowing most particles to pass by the inlet tube while allowing only very small particles and dissolved compounds to enter the analyzer without filtering out the phosphorus-rich solids. Ultrafiltration is often used in wastewater process analyzers to remove all undissolved solids from the sample. Unfortunately, most phosphorus except for the dissolved orthophosphate is removed via ultrafiltration and this is one reason why most of the previous analyzers tested rarely agreed with the lab results. Sample handling and conditioning is the most critical feature of any online wastewater colorimetric analyzer.

Results

The Liquiline System CA80TP Total Phosphorus analyzer was installed in August 2017, and the Township of Wayne is pleased with results thus far. During the first four months of operation, process conditions did lead to plugging of the sample tube, which was quickly detected by the system and resolved by maintenance personnel almost immediately. This quick recovery was because of the straightforward alarm messaging provided by the analyzer. Empty reagent bottles were also detected by the system and corrected by operators with only a minor interruption of the measurement.

The plant is now able to rely on the measurement, adjust the PAC dosing in near real time, and see total phosphorus trends that are in close agreement with laboratory grab-sample analysis. None of these benefits were achieved with the previous analyzers they evaluated. The Township of Wayne is now confident that the analyzer will provide useful predictive alarms to warn of low reagent conditions and when faults are present, they can be resolved quickly, resulting in minimal loss of measurement time.

Heated/ventilated analyzer shelter with 3/4” hose in from submersible pump with bypass back to process.

“When the phosphorus level is starting to rise, we can see that trend in near real time because the samples are taken automatically every 45 minutes,” said Breder. “We go in and make the adjustment right then. These samples yield accurate data and quality results onsite. You basically have real data that agrees with results that are completed in the lab, which take days to process.”

The municipality is already discussing plans to implement digital communications using Modbus TCP or Ethernet/IP to take advantage of the extensive predictive diagnostics from the total phosphorus analyzer in real time over the plant network. Once implemented, important current and historical variables such as low reagent warnings, preventative maintenance warnings, overall instrument health, and historical and current calibration data will be available via the IP addressable web server. User-friendly descriptive warnings can be configured to pop up on the SCADA HMI to give immediate indication of analyzer performance issues without the need to go out in the field to view the instrument display.

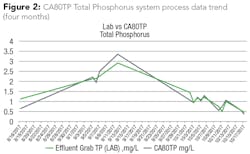

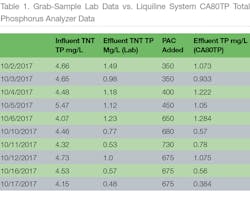

“We eventually want to see this data right from our desktop and not have to manually adjust,” said Schwind (see Table 1 and Fig. 2). “Eventually our computers will do that for us. The ability to run diagnostics remotely from our desk and know that it is going to run properly will be beneficial. As we start and continue to upgrade, the alarms we were receiving are becoming less and less.”

“The end goal is a [total phosphorus] number that you can hang your hat on,” added Breder. “You need good numbers and maximum up-time on the instrument and before using the Endress+Hauser system we weren’t getting superior, reliable and consistent results. If your instrument is not running or your data isn’t accurate, then there is no use.”

Conclusion

The issues the Township of Wayne experienced for control of phosphorus discharge are not unique. Wastewater treatment plants across the United States are seeing tighter permit levels for total phosphorus discharge. These limits no longer allow for control over phosphorus removal solely relying on manual sampling and lab testing. Orthophosphate analyzers do not produce a correct result, given the fact that sample preparation systems used with orthophosphate analyzers remove a portion of the total phosphorus you are trying to measure. The Township of Wayne found that the Endress+Hauser Liquiline System CA80TP Total Phosphorus analyzer measures true total phosphorus using a unique sampling system that provides a truly representative sample, and complete sample digestion, resulting in highly correlated lab quality results. With on-board diagnostics they also found the analyzer allowed them to maximize process uptime. With future plans to upgrade to digital fieldbus communications with a web server, the Township of Wayne will further enhance its ability to manage its phosphorus removal process and easily comply with tighter permit requirements. WW

About the Authors: Howard Breder is the lab manager and Mark Schwind is superintendent of operations for the Township of Wayne. At the time the article was written, Jay Mershon was a product solution business manager for Endress+Hauser and Chris Garaffa was the PCS account manager.

Circle No. 250 on Reader Service Card