Regulations: Drilling for the Facts

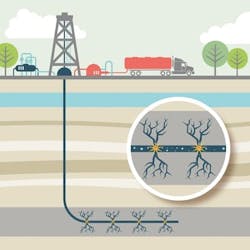

It has been more than 20 years since the combination of hydraulic fracturing and direction drilling was introduced in the U.S. to extract natural gas, and the process continues to be widely used. It has been a hotly debated topic due to concerns about its impact on public health and the environment, specifically on drinking water. Water has long been at the center of this debate, from the amount of water used to fracture a well to the disposal of the flowback wastewater to pollution of drinking water sources.

These concerns prompted the U.S. Environmental Protection Agency (EPA) to study hydraulic fracturing and its impact on drinking water resources. In June of this year, the agency released its draft assessment of hydraulic fracturing and its potential impacts on drinking water sources, and it has created lots of controversy and drawn criticism. The report concluded that fracking does not cause widespread systemic pollution of drinking water resources. The following are the biggest concerns outlined in EPA’s assessment.

Water Withdrawal

With some states experiencing drought so severe that they are making water conservation mandatory, it is harder to make an argument for using water for hydraulic fracturing. Water makes up about 90% of the mixture used to fracture a well, which can add up to several thousand or even several million gallons of water per well. EPA estimates that 44 billion gal per year of water were used for hydraulic fracturing in 2011 and 2012. This may seem like a lot of water, but it represents less than 1% of total water consumption. In certain localities, however, especially those experiencing drought, this can make a significant impact.

Due to the concerns about the amount of groundwater and surface water being used for hydraulic fracturing, there has been a push for gas companies to use recycled water. While some companies have adopted water recycling, its cost and implementation can make it impractical for many companies.

Any withdrawal of water can potentially impact groundwater quality, so one could assume withdrawals of thousands of gallons of groundwater for use in hydraulic fracturing will inevitably have some kind of impact. When groundwater is removed and used at a rate faster than the natural recharge rate, the water level can drop. This can concentrate naturally occurring contaminants from geologic formations or allow water of lesser quality to infiltrate into the groundwater, thus lowering the overall quality. Additionally, these withdrawals can impact the amount of groundwater that feeds streams, thus affecting surface water as well. Withdrawals from surface water also can affect quality by lowering water levels, which affects the ability of the surface water to dilute any contaminants that are introduced.

Chemical Cocktail

The water used in the hydraulic fracturing process is mixed with chemicals and a proppant before being injected. These chemicals are added for a variety of reasons, but typically they are used to adjust pH, increase viscosity and inhibit bacterial growth. While the chemicals make up only about 2% or less of the injected fluid, this can mean thousands of gallons of chemicals when considering the amount of water needed to fracture a well.

Storing these chemicals on site can result in accidental spills, releases or leaks. EPA identified more than 1,000 chemicals used in the fracturing process, including acids, alcohols, bases, hydrocarbons, polysaccharides and surfactants. The most widely used chemicals included methanol, petroleum distillates and hydrochloric acid. Water that returns to the surface may contain these chemicals, plus any naturally occurring contaminants, including heavy metals and possibly radiologicals, depending on the geology of the area.

Spills & Releases

According to the EPA report, spills and releases occur due to human error, equipment failure and containment failure. When looking specifically at 151 spills that occurred on or nearby a well pad, the agency found the most common cause was equipment failure. Equipment used for hydraulic fracturing can fail for a variety of reasons, but the most notable is corrosion. Most recently, a pipeline failure in California led to a spill of more than 100,000 gal of oil.

When evaluating hydraulic fracturing, spills that occur as a result of traffic accidents should be included, particularly those that involve trucks hauling fracking wastewater for disposal, chemicals or fuel. If an accident occurs, the environmental damage can be significant.

The Fracturing Process

In order to protect drinking water sources within the ground, the hydraulic fracturing process involves multiple layers of casing to isolate groundwater. These include a steel casing enclosed in a layer of cement. Although many precautions are taken to protect drinking water sources, things can go wrong. For example, faulty cement or materials, along with improper siting, can lead to contamination of drinking water resources.

Wastewater Disposal Concerns

Water that returns to the surface during the hydraulic fracturing process is commonly called flowback and contains a combination of water, chemicals and naturally occurring contaminants. Approximately 20% to 40% of the water injected will flow back to the surface; the rest will be absorbed into the shale formation. Produced water continuously flows to the surface from the formation throughout the life of the well. While water that comes back to the surface may contain chemicals, heavy metals and radiologicals, it is considered brine waste and can be disposed of by injection into a deep well. There are concerns about how much waste a deep well can safely take on. Additionally, some of these wells have been suspected as possible causes of earthquakes.

While EPA’s assessment claims there is no systemic problem with hydraulic fracturing negatively impacting drinking water, it always poses that risk. Many industries can be detrimental to the environment, so regulations are developed to make them safer and lessen their impact. The concerns about the amount of water used in hydraulic fracturing and waste disposal can be alleviated if more companies adopt the practice of using recycled water.

There are many solutions to lessen the risk to drinking water supplies, but they come at a cost. For example, recycling water is more expensive than buying drinking water. If current trends continue, drinking water supplies will become more polluted, and not just due to hydraulic fracturing. The more contaminated drinking water is, the more expensive it will be, so we need to do all we can to protect this valuable resource.

Download: Here