How to Design RO Systems to Meet Small Commercial Water Needs

About the author: Bill Lloyd is technical service specialist for Dow Water & Process Solutions. Lloyd can be reached at [email protected].

From car washes to hotels to hospitals, the need for effective water treatment is critical for companies to operate. Whether it is drinking water for vending machines and restaurants or food-grade water for processing, increasing demand for high-quality water has OEMs and end users searching for solutions that can meet their water treatment needs efficiently and affordably.

Many operators continue to rely on reverse osmosis (RO) systems to reduce system cost and optimize productivity and water recovery. RO can remove a number of contaminants that can affect small- to medium-sized water systems. RO filtration is used in buildings to provide high-purity drinking water and consistent water quality for light industry.

Designing small commercial RO systems is no small feat. There are many considerations and evaluations to make, including how to calculate the right balance between the size of the system and the size of the storage tank, how to utilize design programs to create the best commercial RO system for the application, and how to understand product data sheets, RO system design guidelines and temperature correction factor (TCF) tables.

To help companies meet specific water treatment requirements, there are a number of advanced software options available on the market with the capability to accurately predict the performance and efficiency of RO systems prior to installation. Reverse Osmosis System Analysis (ROSA) software, an RO system design tool, is one choice for designing small commercial RO systems.

Sizing the System

Most commercial RO systems operate in tandem with a storage tank. It can be difficult to accurately calculate the balance between the size of the system and the size of the storage tank.

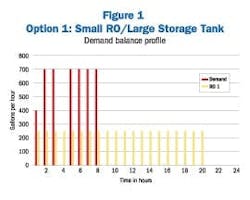

In this case, we will observe two options: a small RO system with a large tank and a large RO system with a small tank. Typically, one would presume that opting for a smaller, less-expensive RO system and a larger storage tank would be most cost-effective; however, that is not always possible due to space constraints. Oftentimes, commercial RO systems are retrofitted into existing buildings and must fit into confined areas.

Option 1: Small RO System (Figure 1). In this example, the customer’s total demand was 4,600 gal per day (gpd); however, a 6,000-gpd RO system was needed. The calculation of RO system size must take into account how many hours per day are available for the RO system to operate. In this case, the end user requested four hours per day for maintenance, leaving 20 hours for RO system operation on a daily basis. As a result, the RO would need to produce 230 gal per hour to meet the customer’s demand.

Converting this flow back to a system rated on a 24-hour basis, it was concluded that a 5,520-gpd system was required. A 6,000-gpd RO system was selected by rounding up.

Option 2: Large RO System (Figure 2). In this case, a projection was run to minimize the size of the storage tank in case the space at the end user site did not allow for a larger tank. Up-sizing the RO system allows for a smaller tank size; sometimes tanks must be sized to fit through existing doors and a large tank is not an option.

Comparing the two options provides a cost analysis. In this scenario, the large RO system and small tank option was less expensive.

Membrane System Design Guidelines

The fouling tendency of feedwater has the greatest influence on membrane system design. Membrane fouling can be caused by a number of materials present in the feedwater and concentrated at the membrane surface, such as dissolved organics, bacteria, particles and other colloidal material.

The silt density index value of the pretreated feedwater can be used as a surrogate measure of the fouling material.

Utilizing RO Design Software

ROSA software is used by many OEMs and end users as an RO system design tool to fulfill their required water treatment specifications.

To begin using the design software, enter the concentration of ions in the feedwater. Next, select the type of element and try different vessel configurations. The software will complete all of the complex mathematics and produce a complete, simple-to-understand report that predicts water quality and flow rate.

Making a selection based on data sheets can be a difficult process. This is because elements are tested under different conditions. The use of a design program helps overcome this problem by allowing a direct comparison either by running element projections or using active area listed in the element specifications to do a direct element to element comparison based on gallons per day per unit of pressure of net driving pressure. Generally, an element that will meet the application permeate total dissolved solids requirements at the lowest operating pressure and pump cost is selected.

Determining Size With TCF

Alternatively, some companies may seek pre-built systems, which usually are rated by gallons per day produced at 77ºF. If design comparisons are done at another temperature, a correction factor must be applied.

The best way to determine the proper unit size is with a TCF table. For example, assuming the TCF for 50ºF is 1.711:

- 6,000 gpd (50ºF) * 1.711 = 10,266 gpd (77ºF); and

- 12,000 gpd (50ºF) * 1.711 = 20,532 gpd (77ºF).

The 6,000-gpd calculation calls for a 10,000- to 11,000-gpd RO system while the 12,000-gpd calculation suggests a 20,000- to 21,000-gpd system.

Some companies only install and service commercial RO systems. In this case, they need to be able to size a system rated at 77ºF to a customer site where temperatures may vary.

There are other factors to consider as well. In single-element systems, concentrate recirculation should be used to increase reco- very. Another key consideration is the ±15% variation from element to element.

Another factor to consider while designing RO systems is the presence of scaling. To prevent this, use a softener in advance of RO treatment. ROSA software can be used to calculate the scaling potential of the water on the Langelier Saturation Index.

Reliable Performance & Quality Water

Whether they are designing an RO system to achieve a spot-free car wash or quality drinking water for hospitals or buildings, many OEMs within small to medium companies rely on a water treatment system that can meet growing demands cost-effectively, without creating inefficiencies or harming productivity.

By using ROSA system design software, companies can tailor their small commercial RO systems to satisfy required water treatment specifications. Ultimately, designing the right RO system for the application will lead to higher productivity and lower system cost.