Water Disinfection Solutions in Aerospace Applications

Mitch Hansen is marketing manager for AquiSense Technologies. Molly McManus is regional sales manager for AquiSense Technologies. Hansen and McManus can be reached at [email protected] or 859.869.4700.

undefinedWhen boarding a flight, your recently emptied water bottle will find no relief. Water fountains and bottle fillers are nowhere to be found in the galleries or lavatories on most commercial flights. This is not caused by a lack of on-board water supply; commercial planes are mandated to maintain a full water tank and plumbing. However, the tanks and pipework on these planes are vulnerable to contamination. The reality of on-board water storage and distribution contamination forces airlines to provide expensive (weight and volume) bottled water to their passengers and flight crews. Offering purified water from the source already available, without the use of expensive bottled water would clearly save airlines time and money. Conventional ultraviolet (UV) disinfection does have limited use to purify the on-board water systems, however, they have limitations in terms of maintenance cost and risk. An new technology utilizing the latest development in UV-C LEDs (ultraviolet light emitting diodes), might play a key role in a solution.

Commercial flights in the U.S. are held to water regulations established by the U.S. EPA. In 2009, the EPA published a water quality study on domestic flights within the U.S. and Canada. The results were alarming. Nearly 15% of all water tanks tested were positive for Coliform bacteria.

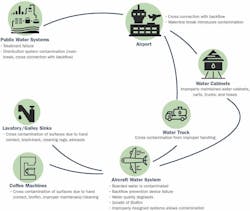

Across the world, airlines and government agencies have limited the use of on-board water tanks for human consumption. The threat of contamination in these tanks leads governments to err on the side of caution and prevent the galley water from being consumed. In some countries, this water can only be used for lavatories and it is common to see signs warning passengers to avoid drinking the water. Although the on-board water may have originated at a reliable water source, it passes through several phases before reaching its destination.

Issues With Water Tanks

The EPA found water tanks in commercial airlines to have consistent bacteria and debris issues. The study concluded that these tanks have residual bacteria and sediment in them. Even after the system is flushed with disinfection chemicals, it is common for small pathogen-harboring particulates and sediment to remain. Even a small number of bacteria in the system can easily grow and spread, perpetuating the contamination.

Current Attempts

Carbon or ceramic filters could be used to remove the sediment. However, these filters typically cannot remove all pathogens and require frequent replacement. Bacteria is commonly treated with chemicals, such as chlorine, however the risk of byproduct formation is a concern when drawing from a wide range of source water. Additionally, chlorine levels are difficult to maintain and measure, especially in mobile systems with limited power, space and personnel. Monitoring the formation rate of disinfection byproducts from chemical treatment and some chlorine resistant pathogens (e.g. cryptosporidium) creates further complication.

UV systems paired with filters are common alternatives when chemicals are not an option. When combined, the filtration removes sediment while the UV light damages the bacteria’s DNA, making the bacteria incapable of reproducing. However, conventional UV systems utilize mercury-vapor lamps, which are susceptible to breaking in mobile applications. If a UV lamp were to break during flight, sharp quartz fragments and mercury could enter the water supply. Mercury UV lamps also run on higher voltages and have limited on-off cycles, resulting in operational constraints.

UV-C LED Solutions

Recently developed LEDs that produce deep UV light affect bacteria in the same manner as conventional UV lamps but offer all the typical benefits seen in semiconductor technology. UV-C LEDs provide the option for versatile reactor design that caters to space and weight constraints of airlines. Additionally, LEDs are mercury-free and rugged enough to survive the vibration and shock specifications without any risk of breakage or contamination. Small size and instant on/off capabilities mean this technology can be placed near the water dispensing point, such as a sink or galley faucet, and switched on only when water is flowing.

Disinfecting the water right before it reaches a user blocks contamination present in the piping and diminishes the need for residual disinfection chemicals. This new UV-C LED technology gives a new alternative to an on-going water problem the airline industry has been dealing with for decades.

Test Applications

UV-C LEDs are currently being tested inside the Boeing ecoDemonstrator. The 2019 ecoDemonstrator 777-200 provides a proving ground for technology being tested for commercial use on future Boeing aircrafts. The UV-C LED system being tested could offer point-of-consumption disinfection for sinks and water fountains throughout the aircraft. If this technology is approved, it will move on to production where it may be installed in all new Boeing aircraft with the possibility to be retrofitted into existing cabins’ water systems, too.

UV-C LED systems are being developed under multiple aerospace applications. These projects cover applications of all types, from keeping growth systems clean in space-bound greenhouses to decreasing the maintenance burden from nuisance biofilm formation in enclosed systems, to disinfecting the water that astronauts drink on the International Space Station (ISS). The current ISS’s water system is only 88% efficient and uses filtration and chemical technologies. A 2010 study completed by NASA showed bacteria can still grow inside the current water treatment system and recommended an alternative be developed.

The Bio-contamination Integrated Control of Wet Systems for Space Exploration (BIOWYSE) Project was commissioned by the Horizon 2020 program to address the efficiency and disinfection issues within the ISS water treatment system. BIOWYSE Project is employing UV-C LED technology for water disinfection. This work is showing that UV-C LED systems can be implemented in aerospace applications. A number of other active projects are currently underway with space applications that are likely to have a positive impact of terrestrial commercial flight water safety.