About the author: Gerry Bulfin is CEO of Clean Water Systems & Stores Inc. Bulfin can be reached at [email protected] or 831.462.8500.

Ongoing drought conditions in many parts of the U.S. are impacting water treatment systems using well water and municipal water alike. This can be advantageous, however, for water treatment dealers who use this as an opportunity to stay in contact with customers and offer education and additional services to help them through the drought.

The 2012 North American drought is a record-breaking expansion of the drought that started in 2010. In response, U.S. Agriculture Secretary Tom Vilsack designated 597 counties in 14 states as primary natural disaster areas. The drought covers 80% of the U.S. and central and eastern Canada. The U.S. Environmental Protection Agency estimates that 15% of Americans rely on private wells for drinking water, and the drought is starting to affect thousands of those wells. The drought also has inflicted catastrophic economic impacts on agriculture and communities in the affected states that rely on groundwater.

Red Flag Changes

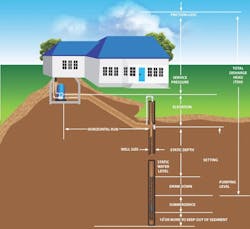

Changing aquifer levels mean that well water levels do not always remain constant. Droughts, seasonal variations in rainfall and the speed at which water is pumped out all affect well water levels. If a well is pumped at a faster rate than the aquifer can be recharged by precipitation or other underground flow, water levels can fall. This is currently happening in some drought-stricken areas.

Often, the first sign a well is impacted by lower groundwater levels is that the well goes dry and the pump breaks suction. The best solution is to first consult a well or pump contractor to determine the depth of water in the well. Often, the well pump can be lowered to take advantage of the existing water table.

It is also common for well water quality to change. The customer may report higher levels of odor, color or sediment, often caused by a drop in the water table, even though they have plenty of water available. Iron bacteria may exacerbate the problem by causing fouling of the well screen, pump and drop pipe.

Rehabilitating a well may help it produce more water and improve water quality. Well rehabilitation restores a well to its optimum condition using various mechanical or chemical techniques. A professional water well contractor can do tests to see if rehabilitation measures will be successful prior to starting the process.

Often, drilling the well deeper or drilling a new well is the only solution to drastically falling water tables.

Treatment System Effects

Well owners often have various types of water treatment systems to achieve potable water. These include iron filters, water softeners, sediment filters, reverse osmosis (RO) systems, nitrate filters and other backwashing filter systems. These systems use water to automatically clean and maintain themselves through regeneration, when the system is backwashed and rinsed to drain.

Many homeowners are unaware of how often these systems regenerate or how much water is used in the process. If a well does not produce sufficient flow and pressure to properly clean and regenerate the treatment system, it will eventually foul and/or require premature service.

Drought also can affect water treatment systems by causing formerly productive wells to pump up sand and grit as the water table drops. In some cases, a system that has been problem free for years begins malfunctioning due to excess sediment.

In Texas, Oklahoma and many other drought-affected areas, parched soil is causing pipelines to snap under high pressure. This can lead to high turbidity, sediment and grit entering the pipelines and fouling residential water softeners and filters. Consumers who use a municipal water source often do not install prefilters, so the sediment can enter the softener or filter, causing damage to control valves and resulting in pressure drop inside the home.

Optimizing During Drought

The drought presents an opportunity to educate customers and encourage routine service calls to optimize their water treatment systems. There are many ways to help customers save money and water during periods of drought by making adjustments.

The first step is to encourage a service call to analyze the water before and after the treatment system to determine if it is working according to the manufacturer’s specifications. A good preliminary step is to ask the customer to provide water samples before and after the system, then follow up with a phone call or mailer to schedule a service call.

If the system is working satisfactorily, consider adjusting the frequency of the backwash or regeneration to save water. For example, if a filter system backwashes every two nights, consider setting it for every three nights to cut water consumption. If it is set for once every four days, consider changing it once every seven days.

Inadequate backwash is often the main cause of fouling, so it is important not to adjust iron filters or other backwash filters too dramatically. After adjustments are made, it is important to regularly monitor water quality.

For softeners, inspect the amount of salt used per regeneration to make sure it is optimal. With newer resins and modern softener designs, settings can often be changed to use less salt and water. Inspect and clean brine valves and injectors. For metered regeneration softeners, inspect the settings and consider increasing the time between cycles, or at least verifying that they are set correctly.

Softeners often achieve higher brine efficiency by using brine injectors that operate at a low flow rate — 0.2-gal-per-minute brine injectors are common. While these lead to greater brine efficiency, they can become fouled if the untreated water gets contaminated with higher levels of sediment and iron. Offer customers 60-mesh spin-down prefilters or other types of prefilters to help reduce injector fouling and damage to piston seals.

Consider reusing the backwash water from the filter system for irrigation. Save for water softeners that use saltwater brine for regeneration, many types of filter systems have backwash water that that can be reused to water plants. Check local regulations first, as some states have restrictions on reusing this wastewater.

Inspect under-sink RO systems to make sure they are not continually running to drain. These systems route a percentage of the water to drain as they make purified water. When an RO system malfunctions, water can be wasted by quietly running to drain continuously.

The wastewater from RO systems can be reused for irrigation and it is not difficult to run some tubing from the wastewater line outdoors for irrigation during months when the weather is not freezing, if local regulations allow.

Conservation Education

During times of drought, educating customers about conserving water and optimizing their water treatment systems is an excellent way to stay in contact. Consider regular e-mails, postcards or courtesy phone calls to your customers, and offer information on water conservation and routine service call reminders.

If the water in an area is hard, softeners can save money and water usage by allowing shorter wash cycles in washing machines and dishwashers.

Encourage customers to reduce daily water use by installing efficient fixtures such as low-flow toilets, faucets and showerheads.

Download: Here