How LIMS can streamline environmental monitoring programs

In drinking water and wastewater monitoring labs, cleanliness is everything. For the labs to accurately determine water quality, environmental monitoring (EM) is vital to ensure that there is no contamination at any stage of sample processing that can affect the integrity of the results, particularly for microbiological testing. To uphold safety and quality, external regulations are in place that water testing labs must abide by, such as those set by the U.S. EPA Water Quality Standards (WQS).

Although it is an integral part of a robust, high quality testing process, EM is no easy feat. Most notably, labs must ensure they efficiently schedule the collection of samples from their own facilities, enabling them to keep their processes running smoothly. In addition to this, labs must also be able to maintain the traceability of their EM samples to ensure they know exactly where any contamination occurs. Failure to do so can be consequential.

The efficiency of the lab’s EM procedures directly influences the quality of environmental testing processes and services. Importantly, substandard scheduling of EM samples can cause environmental testing workflows to be drawn out, thereby reducing profitability of the service. What’s more, any mismanagement of EM samples can lead to inaccurate results, causing significant damage to the company’s reputation. And, in the worst-case situations, these false results can pose a severe risk to human health, as the data may be used to wrongly inform decision making. Consequently, many labs are now asking: what can be done to improve EM, and subsequently environmental testing, efficiency?

Lab information management systems (LIMS) act as a shining beacon that provide direction through a dark haze of scheduling inefficiencies and sample management challenges. Here we explore how LIMS can streamline EM and improve sample scheduling to help companies achieve more with less.

EM: resource-driven and data-intensive processes

When undertaking EM in drinking and wastewater monitoring, labs must collect samples and track them the whole way through to final analysis. The entire process is inherently resource-driven and data-intensive, owing to the vast amounts of data gathered from the samples — but, for effective monitoring and risk analysis, the data must be properly processed.

Effective scheduling is the key to keeping EM processes smooth. This is not only for sample collection scheduling but also for managing testing schedules and addressing any ad-hoc testing for emergencies. At the most extreme end of the inefficiency scale, EM data is sometimes still recorded physically on paper, making traceability highly challenging. As a step up, many labs use spreadsheets or mobile applications for their sample management. Although this approach has some advantages over paper trails, both these methods suffer from several drawbacks:

- Disorganized sample tracking, leading to risk of error and integrity concerns

- Inefficient workflows, meaning a lower sample throughput

- Uncontrolled processes, making it difficult to comply with regulations

So, how does one maintain the accuracy of such high volumes of data while minimizing data integrity concerns?

LIMS: accelerate EM workflows

Switching to digital processes — that is, managing EM using LIMS — is arguably the most consequential step that a lab can take to overcome the aforementioned challenges and streamline processes. Labs that use LIMS benefit from:

- Improved sampling management for greater traceability and efficiency

- Deeper data analysis for improved insight

- Scheduling capabilities to effectively manage samples

Here we delve further into six ways LIMS can make an EM program more robust:

1. Create an EM schedule

As mentioned earlier, a large volume of samples needs to be run for EM, which can be time-consuming and difficult to manage. What’s more, new sample and control points need to be added over time as workflows change, requiring flexibility in existing processes to accommodate them.

Some LIMS feature a scheduler, allowing a lab to plan and manage all its work using a single mechanism from a single location — making sample management more concise and simpler, thereby reducing the time needed to do this task. Flexibility is built in, too, as additional collection points can be easily added or turned off.

2. Enjoy paperless sample ID and selection

EM cannot be performed without sample collection, which requires taking containers from the lab to various field locations. But without a digital solution, it can be difficult to know where these samples came from.

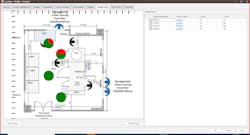

LIMS have a barcoding feature, allowing labs to trace and match collection locations to each specific sample. Not only does this improve traceability, but it also better secures data integrity. With some LIMS, a graphical overview of contamination levels is generated, allowing users to see any problem areas instantly on a map (Figure 1).3. Perform micro testing

To properly investigate any contaminants, a culture of a sample must be created — this is known as micro testing. Fundamentally, micro testing requires initial incubation of the sample with readings being taken, but further incubation is often needed, for example at a different temperature to enable detection of both bacteria and fungi.

LIMS can feature a barcoding capability, allowing users to manage the whole incubation workflow. For added simplicity, some LIMS can provide a notification when users need to remove the sample from the incubator. The barcoding function both improves the process efficiency and enables greater traceability of samples.

4. Monitor and manage samples

EM is complex, and many different areas of the workflow require monitoring and managing, such as sampling and equipment. In addition, the data also needs proper management to obtain the most insight. For example, spreadsheet software can be used to identify trends in results — of great benefit to the analyst — but the process requires manual input of data and, therefore, risks transcription errors and even incorrect trends being identified.LIMS can feature a dashboard that provides clear insight into different areas of the workflow in real-time, giving the user understanding of upcoming workloads (Figure 2). Reports can be generated that help managers identify any delayed processes and remove roadblocks, leading to improved efficiency, reduced workflow times, and higher productivity. As an additional bonus, some LIMS feature automatic trending capabilities, which are robust and timesaving (Figure 3).

5. Record corrective actions

Recording corrective actions in this manner leads to improved accountability of errors, consequently enabling better compliance of procedures with any regulators.

6. Review data

EM requires the production of several reports, including information such as any organisms identified. Using a paper system, this can take up to a day, tying up time that could be better spent elsewhere.

LIMS can generate these reports almost instantaneously, thereby requiring less resources and freeing personnel up for other value-adding tasks. Additionally, they can also provide regulatory data in the right format when it is needed, improving the lab’s compliance and upholding company reputation.

Open the door to streamlined sampling with LIMS

Better data management and efficient scheduling is crucial to improve EM and enable accurate drinking water and wastewater testing processes. LIMS bring the whole process together, illuminating the path to higher productivity and improved data traceability — all while enabling the lab to meet regulatory requirements.

The improved data collection and more efficient processes enabled by LIMS are the key to unlocking productivity in the water monitoring lab, enabling thriving and compliant EM processes with less effort.

About the Author

George Mattis

George Mattis is currently a senior technical solution consultant with the digital science team at Thermo Fisher Scientific, with over 30 years in the information technology industry. He has a B.S. in computer engineering from Rensselaer Polytechnic Institute and an M.B.A. from Northeastern University. He has worked with many of the leading manufacturing companies around the world in addressing their laboratory requirements around informatics, regulatory compliance, and process improvements through his background in laboratory information management systems, integration technologies and digital transformation.