Submersible vs. Lineshaft Vertical Turbine Pumps: Advantages and Limitations

By Allan R. Budris

Several of my past WaterWorld columns have covered vertical turbine line-shaft pumps (VTP; see Fig. 1) and the unique reliability issues that can arise under various conditions, in addition to actions that can be taken to minimize these negative factors.

These unique negative line-shaft VTP reliability issues include the excessive vibration that can result from the flexible motor/discharge head, and the spaghetti-like line shafting that connects the motor to the below ground liquid end pump bowl assembly. This is in addition to shaft straightness issues and potential line-shaft bearing problems, which can be lubricated by either the fluid pumped or by an oil tube feed from the surface.

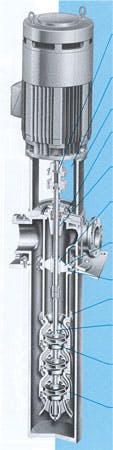

I’ve covered various positive/corrective actions in these columns, such as finite element analyses, sub-critical line-shaft bearing spacing, superior bearing materials and lubrication methods. I did not, however, address the possibility of an alternate pump construction to address these line-shaft VTP issues. A submersible motor driven vertical turbine pump (see Fig. 2) has the motor located below the pump bowl assembly, which eliminates the line-shaft, line-shaft bearing, and motor pedestal components - and therefore the associated vibration/wear vulnerabilities.

There are, however, advantages and disadvantages with both submersible motor, and line-shaft, vertical turbine pump types, depending on the specific application and pump construction. The major pluses and minuses for these two pump types are detailed below.

Advantages of A Submersible Motor VTP

Submersible motor vertical turbine pumps use a submersible motor coupled to the lower portion of a submerged vertical turbine pump so that both are located together in the well.

A submersible motor VTP is generally silent, which is an advantage for heavily congested metropolitan areas. The aboveground motor that drives a line-shaft VTP can at times generate unacceptable noise levels and is less atheistically appealing.

Since a submersible motor VTP does not have tall, aboveground, discharge heads/motors and line shafting, it is not susceptible to potential vibration problems from these components. Short set line-shaft VTPs, with low pressures/axial thrust values are more susceptible to vibration issues than deep set line-shaft pumps, especially in conjunction with a variable speed drive.

In some cases, a submersible motor VTP will have a lower intitial cost since it does not have any line shafting or motor pedestals. However, submersible motors require power cables, which can offset the line shaft cost and could be damaged.

Also, due to not having line shafting and bearing spacing to worry about, submersible motor VTPs can operate at higher speeds, which means fewer pump bowl stages and a small diameter well casing, both of which can further reduce initial costs.

Submersible motor VTPs are more compact and easier to handle, and a submersible motor VTP does not need a pump house to protect an aboveground motor from the weather.

Advantages of a Line-Shaft VTP

Line-shaft VTPs do have some definite advantages over submersible motor VTPs. A submersible VTP motors is less efficient than an aboveground motor because of its smaller (non-optimum) diameter and the possibility of the motor being fluid filled with a dielectric oil. I’ve conducted four comparisons that showed the average submersible motors to be 6.2 percentage points less efficient then the aboveground motors (93.7 percent vs. 87.5 percent). This submersible motor efficiency penalty can be mitigated somewhat for deeper set pumps by the efficiency losses from the line-shaft bearing friction, which can be one to two horsepower per 100 feet of depth.

The submersible motor power factor in most cases can be 5 to 6 percent below the corresponding power factor of a standard motor.

A submersible motor is more susceptible to failure due to overload conditions, low voltage conditions and voltage surges in the power supply than a conventional (aboveground) vertical motor.

Some manufacturers indicate that motor failure rates are higher for submersible motors, since they operate in a harsher environment. The fact that a submersible motor is submerged in the well water means that the motor mechanical shaft seal must operate with any abrasives in the well water, and be subjected to a high pressure for deep set pumps. If the seal or the motor fail for any reason, the whole pump (and motor) must be pulled for repair. As motors age the seals can leak and cables can be subject to abrasion.

With an open impeller line-shaft VTP efficiency loss from the impeller/wear plate wear can be compensated for by vertical adjustment of the line shaft, which is not possible with a submersible motor VTP.

Line-shaft VTPs have a great deal more versatility than a submersible type unit. A line-shaft turbine pump can be driven by a vertical motor, an engine through a right-angle gear drive, a horizontal motor through a right-angle gear drive, by a flat belt pulley or a V-belt pulley connected to an engine.

Installing the pump motor at ground level significantly reduces the cost of installation, repair, inspection, and replacement of the motor. The cost of pulling a motor from a great depth is significantly higher than when working at ground level.

Conclusions

As can be seen from the above, both line-shaft and submersible vertical turbine pumps have distinct advantages and disadvantages, depending on the application. Generally, submersible VTPs are more attractive in short set urban areas where noise and aesthetics are a consideration and where line-shaft pumps have experienced vibration or line-shaft bearing wear problems. Line-shaft VTPs are typically most attractive for deep set applications where motor efficiency and reliability are a major concern. Total life cycle cost calculations would seem appropriate to aid in the final decision.

It should be noted that the above comparisons do not apply to single stage (non-VTP) submersible pumps (see Fig. 3) where the motor is located above the impeller and casing. Such motors are not restricted by small well casing sizes and can often compete in efficiency with aboveground motors.

References

1. Budris, Allan R. “Special Vibration Considerations for Vertical Turbine Pumps,” WaterWorld, December 2016.

2. Budris, Allan R. “Back to Basics, How to Improve Vertical Turbine Pump Reliability Through Optimum Bearing Selection,” WaterWorld, December 2013.

3. Peerless Pump Company. “Submersible Motor Pumps vs. Line-shaft Turbines for Deep-Well Service,” Technical Information Bulletin, Number Nineteen, 2006.

4. Franklin Aid. “Line Shafts vs. Submersibles: Some Big Advantages for the Sub,” Franklin Electric, February 2017.

About the Author: Allan R. Budris, P.E., is an independent consulting engineer who specializes in training, failure analysis, troubleshooting, reliability, efficiency audits and litigation support on pumps and pumping systems. With offices in Washington, N.J., he can be contacted via e-mail at [email protected].