The Impact of Component Material Selection on Pump Reliability

By Allan R. Budris

Selecting the right pump type and sizing it correctly are critical components to the success of any pump application. Equally important is selecting construction materials. The initial cost of these materials is normally the first consideration. Operational costs, replacement costs and longevity of service and repair costs will, however, determine the actual cost of the pump during its lifetime.

Standard pump part materials (such as cast irons, bronzes and low-carbon steels) are typically the least expensive first cost -- and the most readily available for replacement. However, these materials can become more expensive if they cause premature failure and unexpected service and replacement.

Throughout the years, I have consulted on several wastewater lift station applications where the choice of low-cost cast iron for the pump impeller, even when coated, could not withstand the abrasives in the pumpage and/or cavitation, which were often exacerbated by low-flow suction recirculation.

Factors that must be considered in selecting materials for wetted pump parts are, for example, user's experience, expected pump life, intermittent or continuous duty, pumping of hazardous or toxic liquids, condition of the liquid, pump suction energy level, and conditions of service (especially suction conditions).

Corrosion

Corrosion is the destructive attack of a metal by chemical or electrochemical reaction with its environment. Corrosion by itself is usually not a difficult problem; in fact, many materials are available to handle most fluids. It is, however, important to understand the various types of corrosion and factors affecting the corrosion rate in order to select the appropriate materials. It can be quite difficult to choose a material to withstand multiple factors, such as corrosion in addition to erosion and/or cavitation.

A general rule of thumb is to first select materials that will withstand corrosion and then select the one with the most appropriate abrasion and/or cavitation resistance. Further, the corrosive properties of the liquid may vary with one or more of the following liquid conditions: temperature, concentration, purity, velocity, suction pressure, entrained air, and entrained solids.

Abrasive Wear

Abrasive wear is the mechanical removal of metal from the cutting or abrading action of solids carried in suspension in the pumped liquid. The rate of wear for any material is dependent upon the following characteristics of the suspended solids:

- Solid concentration

- Solids size and mass

- Solids shape (spherical, angular or sharp fractured surfaces)

- Solids hardness

- Relative velocity between solids and metal surface

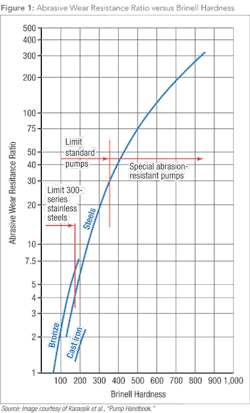

The rate of wear is also dependent upon the materials selected for the rotation and stationary components of a centrifugal pump. Although metal hardness is not the sole criterion of resistance to abrasive wear, hardness does provide a convenient index in selecting ductile materials usually available for centrifugal pumps. Such an index is shown in Figure 1, where the abrasive wear-resistance ratio is shown as a function of Brinell hardness for various materials. It should be noted that a brittle material, such as cast iron, exhibits a much lower ratio than either the steels or bronzes of the same hardness. The following tabulation can also be used as a guide in material selection, listed in order of increasing abrasive-wear resistance:

- Cast iron

- Bronze

- Manganese bronze

- Nickel-aluminum bronze

- Cast steel

- 300-series stainless steel

- 400-series stainless steel

Abrasion-Corrosion

The corrosion rate of most metals and alloys in any liquid environment under static conditions depends upon the resistance of the film that forms on the surface and protects the base metal from further attack. Damage to or removal of this film by abrasion exposes the unprotected base metal to the corrosive environment, and metal removal continues unabated.

When the liquid pumped is corrosive and also contains abrasive solids, higher alloyed materials (such as stainless steel) are often required to achieve acceptable pump life. The use of such alloys is more important when a pump is operated only intermittently and not flushed after each pumping cycle.

In centrifugal pumps, the impeller is particularly susceptible to abrasion-corrosion. Although the casing can be damaged by this, the problem is usually secondary to that of the impeller. The diffuser-type casing with its many vanes is more susceptible to abrasion-corrosion than is the volute-type casing with only one vane -- the casing tongue -- as an obstruction to the line of flow.

Wearing rings are also susceptible to abrasion-corrosion and should receive special consideration in material selection. The higher fluid velocities through the small clearance annulus can result in a high rate of wear, unless the proper material is selected.

Cavitation-Abrasion-Corrosion

Cavitation erosion (which can normally occur with high-suction energy pumps) is the removal of metal as a result of high, localized stresses produced in the metal surface from the collapse (implosion) of cavitation vapor bubbles in higher pressure regions of the impeller inlet. In an abrasive-cavitation and corrosive environment, the rate of damage is further accelerated and can occur even in low-suction energy pumps. The base material is eroded away as the abrasive particles are accelerated towards the impeller surface (by the implosive force of the cavitation bubbles), which continuously removes the corrosion products so metal removal proceeds unabated.

While every effort should be made in the design and application of centrifugal pumps to prevent or minimize cavitation, especially with high-suction energy pumps, it is not always possible to do so. It should be noted that the published net positive suction head requirement (NPSHR) curve is not sufficient to suppress all cavitation damage. It can take four times this NPSHR value, on average, to fully eliminate all cavitation in a pump.

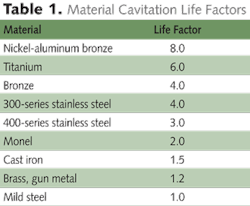

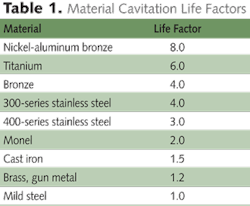

In previous columns, I've discussed recommended NPSH margin ratios. If the desired margins cannot be provided, an impeller material with good cavitation resistance should then be selected. The impact of the impeller material on the life of a high-suction energy pump under cavitation conditions is shown in Table 1. As an example, changing from mild steel (reliability factor of 1.0) to stainless steel (reliability factor of 4.0) would increase the impeller life from cavitation damage by a factor of four. Hard coatings, such as certain ceramics, can also increase the impeller life under cavitating conditions.

Conclusion

In summary, the following criteria should be considered in the selection of the material for a centrifugal pump impeller and/or casing:

- Corrosion resistance

- Abrasive-wear resistance

- Cavitation resistance

- Strength (primarily for the casings)

- Casting and machining properties

- Cost

For most water and other noncorrosive services, bronze satisfies these criteria for the impeller and thus is the most widely used impeller material for these services. Cast iron impellers should generally be used to a limited extent in small, low-cost pumps. As cast iron is inferior to bronze in corrosion, erosion and cavitation resistance, low initial cost would be the only justification for a cast iron impeller. Further, stainless steel impellers are widely used where bronze would not satisfy the requirements for corrosion, erosion and/or cavitation resistance. For the pump casing, cast iron is the generally preferred material in most water and wastewater pumping applications.

About the Author: Allan R. Budris, P.E., is an independent consulting engineer who specializes in training, failure analysis, troubleshooting, reliability, efficiency audits, and litigation support on pumps and pumping systems. He can be contacted via email at [email protected].

More WaterWorld Current Issue Articles

More WaterWorld Archives Issue Articles