New Up-Flow Stormwater Filtration System Can Reduce Treatment Costs

Phase I and Phase II regulations of the Clean Water Act created the need for many facilities to install stormwater treatment devices to remove sediment and other pollutants from runoff. A new treatment system features an upflow filtration design that can reduce clogging, which in turn reduces the size of the filter needed to handle a given flow and also reduces maintenance.

The new filter provides further capital cost savings because it is designed to be used at inlet catch basins for critical source areas instead of outlets, which can reduce the amount of water that needs to be treated in most applications.

Many industrial and commercial facilities will need to treat stormwater runoff as part of the Environmental Protection Agency’s (EPA) National Pollution Discharge Elimination System (NPDES), Phase II Stormwater Program. Phase II is the second component of a two-part program to improve the quality of the nation’s streams, rivers, lakes, and estuaries by managing stormwater runoff from urban and suburban areas, construction projects, and industrial sites.

Phase I, issued by EPA in 1990, covered medium and large municipalities, construction sites over five acres in size, and 10 categories of industrial activity. The Phase II program is the next step and covers smaller municipalities, urban areas adjacent to municipalities, and construction sites over one acre.

Hydro International has been a worldwide supplier of stormwater, wastewater and combined sewer overflow (CSO) products for over 25 years. Previous Hydro stormwater products have been based on hydrodynamic sedimentation. Looking to expand their line with a filtration product capable of removing finer particles, the company’s engineers searched for design ideas that would overcome the problems with conventional stormwater filtration systems. They spoke with Robert Pitt, Professor and Director of the Environmental Engineering Program of the University of Alabama, and one of the world’s most renowned experts on stormwater treatment. Pitt has published 11 books and major Environmental Protection Agency (EPA) reports on the subject.

Working on a Small Business Innovation and Research (SBIR) Grant from the EPA, Pitt had developed and patented a new design for an upflow stormwater filter. The basic advantage of the upflow design is that larger particles fall away from the filter so the full surface area remains available. This greatly increases the flow rate available from a given amount of surface area, which in turn reduces the size and cost of the filter required to provide a given flow rate.

Pitt showed that the upflow design could be improved by incorporating a pre-settling chamber to lengthen the media lifespan and reduce maintenance costs. His design integrated the settling chamber with the filtration chamber to reduce the footprint of the filter.

Hydro International purchased the intellectual property rights for Pitt’s filter and faced the challenge of transforming the design from a research project to a commercial product. Hydro engineers re-engineered the filter to increase its surface area to a maximum of 7.2 square feet, which provides a flow rate of 150 gallons per minute. This is 4 to 10 times higher flow rate than could be achieved with a downflow filter with equivalent surface area. This makes the filter substantially smaller than downflow filters with similar flow rates and reduces the capital investment required for the new filter.

The new filter is also small enough to be positioned on the upstream side of the stormwater system to treat stormwater runoff from critical source areas, such as parking lots, vehicle fueling and maintenance stations, and public works storage areas, at their source. This provides additional savings by reducing the amount of water that needs to be treated.

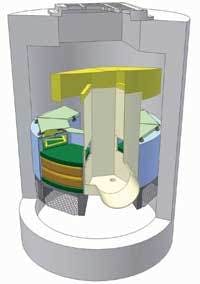

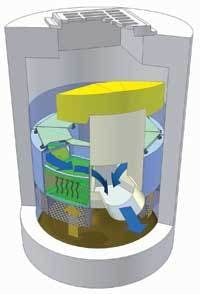

Hydro engineers also worked to improve the maintainability of the new filter. Filters inherently require more maintenance than sedimentation devices because the media must be replaced. In the US, sediment is typically vacuumed out of in-ground stormwater structures. The filtration media needs to be readily accessible and easy and safe to remove and replace. So Hydro engineers designed wedge-shaped filter modules that sit on support frames that bolt to the inner wall of a round or square catch basin. There is a wide clear opening in the center of the catch basin for maintenance access.

Pitt’s original design featured weep holes to allow the water to drain out of the filter media between storm events to prevent bacteria growth. But Hydro engineers were concerned that unfiltered water would drain out of the weep holes during storm events. They designed a series of small weep holes covered with filter fabric. The flow through the weep holes is restricted by the small size of the holes and low porosity of the filter fabric. This allows the filter to drain while ensuring against the release of unfiltered water.

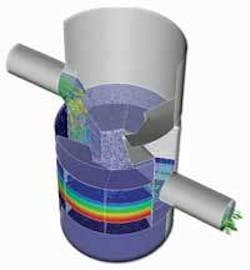

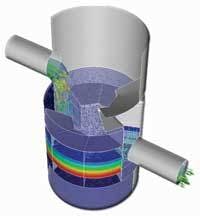

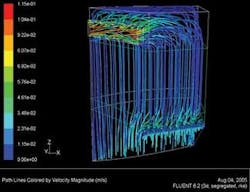

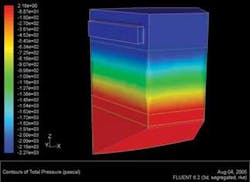

An important part of the design process was simulating the flow through the filter using computational fluid dynamics (CFD). CFD can evaluate the performance of a computational based prototype in much less time than would be required to build and test a physical prototype. CFD also provides more information on the design than physical testing. For example, it can predict flow velocity and direction throughout the analytical domain and can also trace the path of particles of different sizes as they flow through the system.

In this case, CFD showed that in the original design, there was substantial variation in the flow velocity over the media cross-section. This would have reduced the efficiency of the filter because certain areas of the media would have been working at far below their capacity. Hydro engineers solved the problem by adding a layer of flow distributing media just below the filtration media.

The resulting Up-FloTM Filter is the first high-rate, modular upflow filtration system designed to meet the needs of the stormwater market. Its small footprint and high flow rate per unit of filter media distinguish it from conventional downflow and radial flow stormwater filtration devices. The resulting reduction in the size of the concrete filter chamber means the complete installed cost of the new filter is approximately half as much as conventional stormwater filters for the same flow rate. Additional savings can be achieved in many cases because the new filter can be positioned at hot spots to reduce flow rate requirements.

Maintenance costs are also substantially reduced because the new modular filter media is divided into components, the heaviest of which weighs 45 pounds. No heavy lifting equipment is required to replace.

The unique design was recognized by the Environmental Business Journal which awarded the product one of its 2005 Business Achievement Awards. It is now being marketed in the North American and European stormwater treatment markets.