CAS DataLoggers, an Ohio-based data equipment supplier, recently provided the wastewater monitoring solution for a major airport support group whose fluid runoff threatened to endanger the aquatic ecosystem near the airports.

The airport needed a device capable of monitoring fluid discharges into local waterways. The company routinely sprayed de-icing and anti-icing solutions onto their aircraft before they took off when conditions were conducive to ice formation, as mandated by FAA guidelines. Between 100 and several thousand gallons of de-icing fluid were used per aircraft application. While a portion of the fluid stuck to the planes, approximately 75 percent to 80 percent of the treatment would flow into the surrounding environment as runoff.

The bases of many de-icing fluids contain propylene and ethylene glycol which is also used as antifreeze in cars. While the de-icing solutions were being reformulated to be less toxic, there was still concern about the potential impacts of the fluids on the local environment. As government agencies were developing water runoff guidelines for the airport de-icing procedures, this support group was going to great lengths to monitor their run-off to accommodate future regulations and lessen the environmental impact.

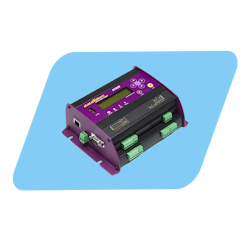

CAS DataLoggers applications engineers determined that a dataTaker DT82EM data logger, equipped with an LTE cellular modem connected to an ultrasonic flow meter, could immediately provide the airport with remote online access to both current and historical data on discharge and flow volume.

The DT82EM system featured analog, digital, and serial sensor interfaces, local data storage, smart power management, and batteries all incorporated into a single unit. The data recorder also powered the sensors and provided the necessary calculation to derive both the flow rate and cumulative flow volume.

Data was transmitted from the data logger, which was located near the wastewater discharge point, to the company’s server via the Microhard LTE Cube cellular modem. The wastewater flow was captured by an ultrasonic open channel flow meter which provided two 4-20 mA outputs — one for the flow velocity and one for the liquid level.

Using this data along with information on the cross-sectional area of the discharge pipe, the DT82EM could calculate the flow rate and totalize the volume to capture and measure open channel flows. The solution was mounted in an IP67 weather-resistant enclosure, guaranteeing extreme durability. It had ultra-low power requirements, and the unit was further supplemented by solar power.

The data logger’s many added capabilities helped staff to monitor the wastewater runoff more efficiently. For ease of use, airport staff could remotely configure the logger, and view both live and historic sensor data. The dEX2 software provided an easy-to-use tool to configure the data logger, build dashboards, create graphs, and download stored data.

Benefits

This complete solution was rapidly installed and implemented. The customer instantly benefitted from the installation of the DT82EM wastewater monitoring system in several key ways.

The data logger eliminated the complexity and cost of manually collecting and organizing the data from the airports' remote sensors. Easy operation by personnel without relying on IT infrastructure became apparent as well.

The advanced data display features allowed the airport group to more easily and efficiently monitor the run-off. Alarm conditions and recipient lists could be created, and alarms could be distributed via email or SMS text message. Each measurement alarm could be independently enabled or disabled, and all alarms were stored locally as well as transmitted to the central monitoring points.

About the Author: Terry Nagy is the Engineering Manager at CAS Dataloggers. He has been involved with test and measurement systems, data acquisition and data logging equipment for over 35 years.

About the Author

Terry Nagy

Terry Nagy is the Engineering Manager at CAS Dataloggers. He has been involved with test and measurement systems, data acquisition and data logging equipment for over 35 years.