Blending Systems Can Help Meet Arsenic Rule Requirements

According to industry estimates, approximately 4,000 communities in the United States are faced with employing additional strategies to comply with the new arsenic content standard, which went into effect in January. These communities have several alternatives to consider when deciding how to deal with their compliance challenge: treatment, non-treatment, or a mix of both options. While much attention has focused on treatment technology to remove arsenic, other alternatives may provide a simpler and less costly method of compliance.

One non-treatment alternative is to blend two water sources to achieve acceptable levels. This is possible when a community has either wells or surface water sources that have arsenic levels well below 10 ppb that can be blended with water that has unacceptably high arsenic levels.

Available treatment technologies include filtration, co-precipitation and the use of arsenic absorbent media that can lower concentrations to acceptable levels. Most of these treatment options can be costly and the desired results may be difficult to achieve in a timely manner. According to the latest EPA Arsenic Treatment Technology Handbook, installation of an arsenic treatment system for wells producing 2-3 mgd can cost as much as $1 million. Moreover, operations and maintenance costs for such systems are estimated to be more than $100,000 annually.

Source Blending

For communities that are lucky enough to have complying water (<10 ppb) as well as noncomplying water (>10 ppb), source blending is likely to be the most cost effective option for them to pursue.Using this approach, water with elevated arsenic content is blended with another water source with arsenic levels significantly less than 10 ppb, using a combination of automatic control valves installed on each drinking water system well line to control a blend ratio that results in arsenic levels below the prescribed EPA limit.

One example of a valve that is suitable for blending such streams is the Cla-Val 131 Series Ratio Control Valve.

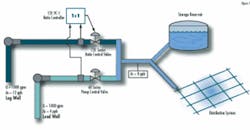

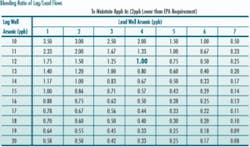

The diagram with this article illustrates a typical setup where the lead well is the better water source than the lag well. In order to maintain an acceptable arsenic level to 8 ppb, the blend ratio should be one-to-one. This means that if the lead well produces less than 1000 gpm, the lag well must track this change and automatically throttle the ratio control valve to the same flow as the lead well. Flow meters on each line provide the feedback to an electronic valve controller, which modulates the ratio control valve. A “Cap Flow” control valve serves to limit maximum output and control startup surges.

For blending to meet arsenic levels other than 8 ppb, use the equation:

Q ratio = (AsLag - AsBlend) / (AsBlend - AsLead) where

Q ratio = Lag well flow / Lead well flow

AsLag = Lag well arsenic (ppb)

AsLead = Lead well arsenic (ppb)

AsBlend = Blended maximum arsenic (ppb)

For example, if the higher Arsenic Lag Well is 12 ppb and the lower Arsenic Lead Well is 2 ppb with a desired 5 ppb blended level the Q ratio (Lag flow / Lead flow) = (2-5) / (5-12) = .43. If the Lead Well delivers 1000 gpm, then the Lag Well must be limited to 1000 x 0.43 = 430 gpm in order to achieve an arsenic level of 5 ppb going to distribution.

Partial Treatment Blending

If a community does not have any water sources that are below the limit, and cannot or will not absorb the cost of treating all of their water, they may be able to use a partial treatment approach where only a portion of the water source is treated to remove most of the arsenic and remixed with untreated water with higher arsenic content to meet the prescribed EPA levels.

When employing the partial treatment blending approach, a ratio control valve can be used to proportionally split the flow so that one portion is treated to remove arsenic and the remaining raw water is remixed after the treatment process to provide water for the distribution system that meets regulatory requirements. If the treatment process removal rate changes with time, the ratio factor may need to be adjusted periodically. Monitoring raw and treatment arsenic levels will determine the split ratio.

Other variations of this strategy include source blending in combination with partial treatment blending. Regardless of the method selected, the objective is to minimize treatment costs while limiting arsenic to an acceptable level.

Additional Functions

In addition to electronic ratio control, hydraulic pilots can be incorporated into the valve to control upstream and downstream pressure. That way, the valve can also be set up to operate hydraulically in the event that power or input signal from the meter is temporarily lost. WW

About the Author:

Roger Lah has been with Cla-Val Co. of Newport Beach, CA, for more than seven years and was instrumental in the development of the company’s electronic valve control product line. His education includes a Bachelor of Science in Agricultural Engineering with an emphasis on irrigation systems and hydraulics from Purdue University, and a Master of Science degree from the University of Illinois, also in Agricultural Engineering