Cyclical Aeration Control

By Michael Saunders

With increased effluent pollution restrictions on municipal wastewater treatment plants, cities are pressed to find ways to economically increase their effluent quality with little to no funding. Many new NPDES permits require the reduction of nitrate and/or phosphorus as nutrient removal becomes more prevalent due to the effects of nitrogen and phosphorus on discharge receiving streams. Biological nutrient removal (BNR) describes the removal of nitrogen and phosphorus by utilizing the naturally occurring biology in activated sludge. Typically, a BNR plant upgrade requires additional capacity in the form of an anoxic or anaerobic basin, which requires significant funding to complete. According to a fact sheet published by the U.S. EPA, Biological Nutrient Removal Processes and Costs, a plant between the flows of 0.1 to 1.0 MGD requires $6,972,000 per MGD for a BNR system upgrade, on average.

One option to avoid the construction of an additional anoxic basin is to convert the aeration system to an intermittent aerobic/anoxic cycle structure. However, typical aeration equipment designed to operate 24/7 lacks the turndown capability required to promote anoxic conditions. Retrofitting these oxidation ditch systems with the proper aeration equipment and an aerobic/anoxic cycling strategy can eliminate the need for an additional anoxic basin.

Typical BNR Design

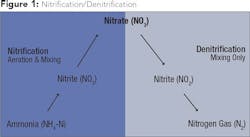

The idea of biological nitrate removal is to stress the bacteria into removing nitrogen by creating a specific environment other than the aerobic condition. A typical BNR plant requires an anoxic basin for nitrogen removal. The definition of anoxic is the absence of residual dissolved oxygen. Anoxic conditions promote the denitrification process (i.e., the reverse process of nitrification). A lack of residual dissolved oxygen will stress the bacteria to find an alternative source, which is in the form of nitrate (NO3-N). The bacteria will utilize the oxygen from the nitrate converting the nitrate to nitrogen gas, which is denitrification (see Fig. 1).

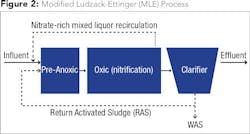

Conventional BNR design includes an independent anoxic basin ahead of the aerobic basin. Since the incoming BOD increases the rate of denitrification, the anoxic basin is placed ahead of the aerobic basin. The anoxic basin will require an additional pump to recycle nitrates from the end of the aerobic basin and designated mixing equipment. The most common BNR design, the Modified Ludzack-Ettinger (MLE) process, is depicted in Figure 2.

Retrofit BNR Design

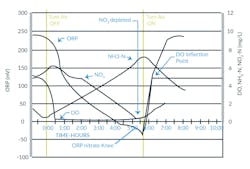

One alternative method to the MLE process is to create anoxic phases within the aerobic basin. Turning aeration equipment off within an aerobic basin will naturally create anoxic conditions. When the nitrates are completely depleted, the aeration can be turned back on to remove ammonia and BOD. As the aeration phase continues the nitrate concentration within the basin will slowly increase until it is time to turn off the aeration system again. This is referred to as cyclical aeration control (see Fig. 3).

Process instrumentation is typically used to target the most optimal times to engage or disengage the aeration system. Oxidation reduction potential (ORP) and ammonia/nitrate probes are the most common instrumentation to use for cyclical aeration control. ORP probes require a significant amount of troubleshooting to calibrate to a specific system, while ammonia/nitrate probes do not require much troubleshooting but are relatively expensive and inaccurate at nitrate levels below 1 mg/L.

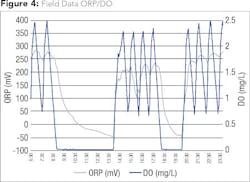

Actual field data is illustrated in Figure 4 for ORP and DO. It shows two denitrification periods, one in the morning and one in the afternoon. During the aerobic periods, DO probes are used to control the blowers to keep the residual oxygen within a set range, in this case 0.75-2.5 mg/L. The control program will turn off the blower at a specific time in the morning, determined through field calibration. Once the blowers are turned off, ORP probes are utilized to determine when the nitrates have been completely depleted, which is when the blowers are to be turned back on. Field calibration is required to determine when the blowers should be turned off for denitrification, which is when there is a high buildup of nitrates.

There are some downsides to cyclical aeration control. Designating a portion of the day to anoxic time will reduce the time available to remove BOD/ammonia. Thus, the same amount of oxygen must be induced into the system during a shorter timeframe, which requires more installed aeration power. Also, excess hydraulic capacity must be available to retrofit an existing basin to cyclical aeration. In order to completely nitrify, a specific amount of aeration time must be provided. Increasing the sludge retention time (SRT) can make up for the reduction in aerobic time, but the sludge age can only go so high (<40 days). Also, enough hydraulic capacity is required to dilute the influent ammonia sufficiently below the effluent requirement so limits can be met during the anoxic phases.

Cyclical Aeration Instrumentation

ORP is a measure of the potential of a chemical to acquire electrons and therefore be reduced. In the case of denitrification, ORP is measuring the redox of nitrate (NO3-) to nitrogen (N2). With a high nitrate concentration the ORP measurement will also be high since there is a high potential of electron transfer. As denitrification takes place the nitrates will be converted to N2 gas, in turn reducing the ORP measurement. When the nitrates are nearly depleted there will be a slight change bump on the ORP curve. At this point, the control strategy recognizes the “nitrate knee” and engages the aeration system.

Figure 3. ORP Control

Field Data: Braidwood, Illinois

The Braidwood, Ill., Wastewater Treatment Plant includes a three-ring oxidation ditch system with AIRE-O2 Triton® aerators installed in all three rings. The current NPDES permit includes a monthly average BOD and ammonia nitrogen of 10 mg/L and 0.7 mg/L, respectively. Total nitrogen is monitor-only, but limits are expected to come soon. Since total nitrogen limits are expected in the near future, ORP and DO instrumentation have been installed for intermittent aeration control. Currently the system is utilizing the ORP aeration control in the outer and middle ditch, while the inner ditch is operating as an aerobic polishing basin.

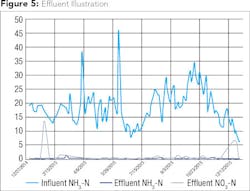

Figure 5 illustrates influent and effluent nitrogen throughout the year of 2015. The effluent nitrogen levels of ammonia and nitrate are consistently low despite a couple of nitrate spikes. The figure also demonstrates that low ammonia and nitrate levels can be met simultaneously within the same basin given the correct control strategy and capacity with intermittent aeration.

Conclusion

Nutrient removal will only become more prevalent due to the impact nitrogen and phosphorus are having on receiving water bodies. Municipalities will be forced to find ways to increase treatment capability while staying under budget. Intermittent aeration control is one option to improve treatment capability while using existing equipment and infrastructure. The only requirements are instrumentation, a new control strategy, and aeration equipment capable of independently aerating and mixing.

About the Author: Michael Saunders has been an applications/project engineer at Aeration Industries International for the past four years. He has experience developing secondary wastewater treatment designs for a variety of applications in the municipal, industrial, and international fields. He graduated from the University of Minnesota-Duluth in 2012 with a BS in civil engineering.

References

1. Wiesmann, Udo, In Su Choi, and Eva-Maria Dombrowski. Fundamentals of Biological Wastewater Treatment, Weinheim: Wiley-VCH, 2007.

2. Tchobanoglous, George, et al. Wastewater Engineering: Treatment and Resource Recovery. McGraw-Hill Education, 2014.