Cleaning System Improves Performance Of Wedge Valves in Large Pipe Applications

A new valve system for large diameter pipeline applications includes a cleaning feature that keeps the valve free of sediment and other obstructions. At the same time, the valve is designed to improve flow performance and reduce maintenance downtime.

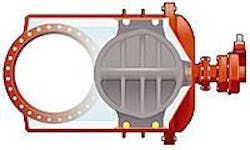

Clow Valve Co. recently introduced a resilient wedge valve with CleanTrack™. The new cleaning system allows operators to install large resilient wedge valves horizontally without risk of sediment buildup in the track.

CleanTrack refers to a unique roller-scraper system featuring bronze scrapers affixed to the valve wing. They automatically push sediment from the stainless steel track in the valve body when it is opened or closed.

Choosing the best valve for large diameter pipeline applications can be challenging. Despite a variety of options on the market, there are mechanical and financial issues inherent in each valve design.

"It's a constant challenge weighing the relative strengths and weaknesses of each design when making a decision," said John Corrella, Coachella Valley Water District, CA. "Although butterfly valves are less expensive in applications over 18 inches, the nature of their design creates an obstruction which inhibits flow and limits cleaning options."

On the other hand, when Corrella specifies gate valves for large diameter pipelines, they have to be installed horizontally which results in unwanted sediment buildup. On larger irrigation systems in his district, Corella's only viable option is specifying expensive plug valves.

Clow designed its CleanTrack system to answer some of those issues.

"This new design gives water systems the bubble-tight seal of a plug valve, the unobstructed flow of a resilient wedge valve, plus the flexibility of horizontal installation without worrying about sediment buildup," said Mike Vore, general sales manager for Clow Valve. "This unique design feature makes the horizontal placement of resilient wedge valves a viable option for larger pipeline applications."

By constantly eliminating any sediment in the system, the cleaning mechanism also reduces maintenance cost by eliminating the need to dig up valves for cleaning. The new resilient wedge valves with CleanTrack™ meet or exceed AWWA requirements.

Features of the valves include Delrin thrust bearings above and below the thrust collar to reduce friction and minimized operating torques. Two O-ring seals are replaceable with the valve fully open and subjected to full-rated working pressure. O-ring seals at the stuffing box and bonnet-to-body flanges ensure the best possible seal. There are no flat gaskets. A 100 percent coated wedge ensures bubble-tight seals up to 250 psi. All valves accept full size tapping cutters. The valve's fusion-bonded epoxy coating, both inside and outside the valve, conform to AWWA C-550 and NSF 61.

The Clow CleanTrack™ feature is currently available in 30 and 36-inch resilient wedge valves. For an online demonstration of Clow CleanTrack™ technology, visit www.clowvalve.com/ C2T2.