New Valve Solves Control, Pressure Challenges

In Southern California's semi-arid climate, the Santa Margarita Water District relies on imported water to supply its 48,000 residential and commercial customers.

At its Plaza Pump Station, one of 17 in the district, source water was coming in through a hydraulic control valve, which wasn't functioning consistently. The high-pressure differential was a concern because it was causing cavitation in the control valve. And the district was unable to measure the amount of water being pumped from another water agency.

"Sometimes we'd pick up too much water, sometimes not enough," said Steve Notch, senior maintenance mechanic for Santa Margarita Water District. "We were breaking 100 pounds of pressure across that valve. In addition to not knowing how much water we were flowing, the valve was cavitating itself to death."

Notch needed a valve that could handle the pressure in the cavitation zone. His first consideration, a ball valve, wouldn't suffice. After successfully testing Singer Valve's Anti-Cavitation Trim for six months at another trouble spot, Notch thought a similar valve could solve the pump station problem.

"Our first Singer valve worked great," Notch said, "so it was natural to look into other applications."

After speaking to Bob Wiltshire, a Singer field representative, Notch discovered he could add features to a Singer valve, just like buying a car and ordering the options.

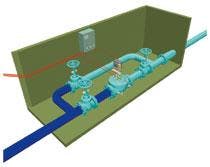

In June 2001, the district installed Singer's MV – Electronic Control valve – a solenoid flow control valve with metering functions that allows Santa Margarita to control and verify the volume of water taken. And it has an automated control panel so the valve can be monitored either on site or from a remote location.

"Now we can break 100 pounds of pressure across that valve," Notch said, "and it solves the guessing game of how much water we're flowing."

"When an agency bills us and tells us how much water we used for the month," he added, "we verify the volume with our Singer Metering Valve."

The Singer MV valve is ideal for limited space. Straight runs are unnecessary for accurate readings. The valve is housed in a weather-tight box that interfaces with a PLC and measures within 2 to 5% accuracy.

The Santa Margarita Water District has since installed six Singer valves and has added the company's control systems on other valves.

For more information on the company's products, visit the Singer Valve website at www.singervalve.com.