Managing Water Loss with Pressure Reducing Valves

By Brad Clarke

Water loss is a significant problem worldwide in potable water distribution systems. System losses vary by utility, but water losses ranging from 15% to 70% have been reported. Good pressure management is one of many solutions to reducing water loss and it is typically the most economical approach with immediate results. There is a direct correlation to pressure and leakage; if you reduce pressure by 1% you will reduce leakage by approximately 1.15% (subject to variation).

When a utility undertakes a major water loss project, multiple control zones with a single source of water (if possible) are required. These zones are referred to as DMAs or District Metered Areas. It is common for a mid to large sized utility to establish hundreds of DMAs.

To insure that clients have enough pressure to serve their needs while eliminating over pressures, each DMA requires a meter as well as a pilot-operated control valve. Control valves are built to different standards worldwide and vary from manufacturer to manufacturer. Different quality materials may be used by different manufacturers. There are also many options that can be added to increase the life of these valves or that can make maintenance easier. AWWA has a standard (Standard C530) for pilot operated control valves that is highly recommended.

Here are some options when it comes to pilot operated control valves for reducing pressure and leakage:

Standard Pressure Reducing Valve

A standard pressure reducing valve (PRV) is familiar to most users worldwide. For a utility that is undertaking pressure management and establishing DMAs, this is often an excellent selection. This valve has typically one pilot and one pressure setting. Operators manually set the pilot to the one pressure they desire downstream and that is the pressure they get. Downstream pressure setting is maintained as a constant regardless of varying upstream pressures or flow rates. This style of valve needs a differential pressure of 10 psi or .6 bar between the inlet and outlet of the valve to function effectively. To change pressure, the operator must adjust the valve manually by changing the pressure setting on the pilot. This style of valve works very well with medium to high system pressures. If available pressure differential drops below 10 psi (.6 bar), pressure reducing valves can not open fully and, as the available pressure drop is further reduced, flow approaches zero.

Low Pressure PRVs

If very low pressures are encountered during peak demand periods, standard PRVs can not supply the required flow. If inlet pressures drop below 10 psi (.6 bar), the differential pressure across the valve is not enough to maintain the valve in the open position. The valve capacity is reduced and downstream customers may not have enough water. This issue can be overcome by using two pilots. The first pilot is a standard PRV pilot that is used to control or reduce pressure at non-peak usage periods. The second pilot is a modified altitude pilot that allows the main valve bonnet to vent to atmosphere at a predetermined low pressure (usually just below the downstream set-point). When the inlet pressure drops below the low pressure setpoint, the main valve opens fully, minimizing pressure loss through the fully open valve at peak demand periods. The valve can open fully even with pressures as low as 2 psi (.13 bar).

A standard PRV typically has the pilot set for the lowest pressure required at peak demand to make sure that all users have enough pressure to satisfy their needs. Remember that the outlet pressure setting remains constant, regardless of variances in inlet pressure or flow rate. At non-peak usage periods (night), there is less demand on the system so pressure loss though the distribution and service mains is much less, resulting in higher downstream pressures especially in areas remote from the PRV. At non-peak times, the increased pressure has two negative outcomes:

1) Leakage rates increase

2) Pipe bursts tend to correspond to higher pressure periods

The above scenario can be overcome in part by using two standard PRV pilots on the main valve. One PRV pilot is set for the high demand pressure (day time) while the other pilot is set for low demand pressure (night time). A solenoid valve is supplied and a basic timing controller decides which of the two pilots is used based on the time. Depending on availability of power, a standard solenoid with a locally sourced timing device may be used or, alternately, if no power is available, a battery operated timer (submersible) combined with a latching solenoid valve using minimal power may be used. The above options can be very economical with excellent results. One consideration is the fire department minimum pressure requirements.

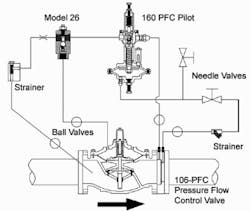

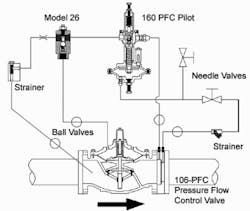

Pressure Reducing Valves – Self Adjusting Based on Flow (Pressure/Flow Control)

Combination pressure flow control valves can be a very interesting option. This style of valve senses flow through pressure differential across either a correctly sized orifice plate or partially open gate valve down stream of the PRV. The standard PRV pilot has a large secondary diaphragm operator that adjusts the pilot setpoint based on flow. The PRV pilot is set for minimum (night) pressure. The secondary operator then increases the setpoint as the flow increases. Minimum setpoint and pressure increase are determined to assure adequate pressure in all parts of the DMA at peak demand. Limitation of this style of valve is that it must be a single source to a DMA. Multiple valves feeding a DMA will not function correctly.

PRVs Incorporating Third Party Control–Time Switched or Flow Modulation

When using this type of control, a standard PRV, complete with main valve and pilot, is used. A third party manufacturer of controllers and interface units will adapt its equipment to interface with the PRV manufacturer's pilot. Usually a Bias chamber will be mounted under the pilot or an actuation device will be mounted on top of the pilot depending on the controller manufacturer.

Flow modulation will react to flow variations in the system and adjust the pressure accordingly. If flow modulation is not required, then time based control can be used with this equipment as an option.

PRVs using Motor Driven Pilot Interfacing with SCADA

In this case a sturdy slow speed 24 vDC (AC option available) motor operated device is fitted to the top of the pilot and attaches to the adjustment screw. This device requires less than 1 amp to operate and is controlled by a 4-20 mA signal from the water distribution SCADA system. The very low power requirement lends itself well to a solar powered self contained station. Extended power failure would result in constant pressure at the last setting.

Pressure transmitters (upstream and downstream) can be used in conjunction with flow transmitters at the DMA so that real time data is available on SCADA. This information allows continuous adjustments of pressures based on flow demand. WW

About the Author: Brad Clarke is the VP of Sales and Marketing for Singer Valve Inc, a designer and manufacturer of automatic control valves. He has spent the last 35 years working in the water industry and has written and presented several papers around the world. on key issues that improve the operation, conservation and management of water systems.More WaterWorld Current Issue Articles

More WaterWorld Archives Issue Articles