High pressure homogeniser process destroys biosolids

By Rob Stephenson, John Shaw, Scott Laliberte, Peter Elson

Wastewater treatment plants world-wide are being squeezed in a classic Catch 22 situation; by treating wastewater to higher discharge standards demanded by regulatory agencies, plants generate more biosolids for disposal. These biosolids, in turn, create another treatment headache since they are smelly and costly to dispose, and the volume of biosolids continues to increase. For every million people, about 25 football fields of biosolids, each one-metre-deep, are generated annually.

The MicroSludge™ process, developed by Paradigm Environmental Technologies in Vancouver, British Columbia, Canada, helps plant operators address this Catch-22 predicament. MicroSludge is a simple chemical and pressure pre-treatment process that radically transforms the rate and extent that waste-activated sludge (WAS) is degraded in a conventional anaerobic digester, the workhorse of a wastewater treatment plant. MicroSludge uses alkaline pre-treatment to weaken cell membranes, mechanical shear to reduce particle size, and an industrial-scale homogeniser to provide an enormous and sudden pressure change to burst cells. The resulting liquefied WAS is then degraded in the existing anaerobic digester, three times faster and 19 times better.

MicroSludge makes anaerobic digesters more effective within the plant's limited available footprint to destroy biosolids, thus avoiding large capital expenditures for added sludge management infrastructure. It also destroys pathogens, reduces odours, and yields vastly lower quantities of stabilised biosolids for disposal. Further, MicroSludge reduces net operating costs by generating higher volumes of methane for combined heat/power generation, and by operating digesters more efficiently, lowering inputs for heating and mixing.

Conventional municipal wastewater treatment typically involves mesophilic anaerobic digestion of both primary solids and secondary solids (WAS) from aerobic biological treatment to produce methane and carbon dioxide (see Figure 1). This biogas can be used as fuel in a micro-turbine to generate heat and power, both of which are used in the treatment plant. Waste heat can be used to dry residual biosolids after digestion to produce a dry and stable product.

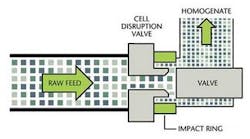

The heart of the MicroSludge process is an industrial-scale homogeniser that provides a large and abrupt pressure drop. At 12,000 psig (82,700 kPag), sludge in the cell disruption homogenising valve is accelerated up to 305 meters per second in about two microseconds. This high velocity flow then impinges on an impact ring, disrupting cell membranes and liquefying cells.

Using off-the-shelf equipment, the patented process has proven to be extraordinarily effective in destroying WAS. Bench and pilot scale testing at a municipal wastewater treatment plant in Vancouver, Canada, demonstrated that 90% reduction of soluble COD after five days and a 97% reduction after 15 days of mesophilic anaerobic digestion of WAS. In contrast, conventional anaerobic digestion of WAS resulted in 17% destruction after 15 days. Volatile solids were reduced by 78% after five days of mesophilic anaerobic treatment. Without pre-treatment, after 15 days, conventional mesophilic anaerobic digestion resulted in 41% VS reduction.

Higher levels of organics destruction generated correspondingly higher volumes of digester gas, providing a substantial net energy surplus for electricity, digester heating, and drying of residuals.

The final sludge that results from the MicroSludge process is safer, more stable and far less than the sludge produced by conventional methods. Conventionally operated mesophilic anaerobic digesters can be readily transitioned to MicroSludge without disruption and with large gains in performance.

Rob Stephenson, John Shaw, Scott Laliberte and Peter Elson of Paradigm Environmental Technologies Inc. are based in Vancouver, British Columbia, Canada.