Alternative wastewater treatment produces energy and saves water

By Christine Nicklas, Dr. Helmut Lehn

Biogas technology is gaining ground in Germany, China, India, Nepal and other countries because it is a local source of energy supply that reduces dependency on foreign oil- or gas-producing countries. Decentralised co-generation of electrical power and heat from biogas offers savings in primary energy and reduces transmission losses, and smaller facilities are less attractive to possible acts of terrorism. In addition, biogas production from animal or human manure is continuously available because manure is produced at any time, buffering peaks from solar and wind energy.

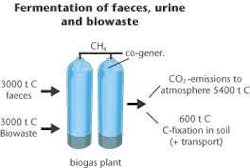

Wastewater treatment in the traditional flush-and-discharge system consumes considerable amounts of water and energy, which is mainly needed in the aeration process to facilitate aerobic bacteria life. Direct anaerobic treatment of traditional municipal wastewater is not feasible due to the high dilution of human manure. Only one percent of wastewater consists of urine and faeces; the rest is drinking quality water added merely for transportation, and mixing with rain leads to further dilution. Instead, anaerobic treatment of human manure from low-flush toilets, favourably combined with biowaste like food waste or grass clippings, can make full use of the benefits of anaerobic treatment, saving fossil energy instead of wasting it, counteracting climate change through CO2-savings and contributing to global sustainability.

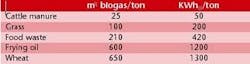

In agriculture, the technology of biogas production from animal manure has long proven its feasibility. Regular feeding of a biogas reactor with manure and plant residues yields biogas (~70 % methane (CH4), 30 % CO2), a renewable energy source, and fermented manure, which is an excellent fertiliser.

Farmers all over Germany now produce energy in addition to food following recent enactment of a law that guarantees a fixed price for generated electricity. The law is intended to enhance market opportunities for renewable energy resources. It guarantees minimum compensation amounts of e.g. 10.23 Euro cents/kWhel for newly commissioned installations for a period of 20 years after the year of commissioning (different size classes). Today the break-even point of economy (supported by this law but also highly dependent on investment promotion) is at about 100 livestock units (about 100 cows or other livestock with the same overall weight) plus 10% co-fermentation from the addition of grass, corn and other biowaste.

The biogas is used by burning in co-generation units for the concurrent production of electricity and heat. Part of the heat is needed to enable bacterial life at 37°C (mesophilic) or 55°C (thermophilic) in the biogas reactor itself. The energy required for heating and stirring the biogas reactor is about 20% to 25% of the energy yield. Larger co-generation units yield more electric power. Currently, engines have an electrical effectiveness from <25% to> 40%; thermal effectiveness is higher with yields of 27% to 50% of primary energy. Co-generation makes the most effective use of available primary energy.

Generated electricity is fed into the power grid, while heat can be used for various purposes, e.g. heating of houses and public baths through local distribution nets, heating of groceries and pigsties nearby the reactor. On-site underground containers filled with water and pebbles facilitate seasonal storing for most effective heat use all year round. If potential users are not situated nearby, a granulate material (alumina silicate) will make heat transportable. Previously heat-dried material will release stored heat when in contact with humid air.

The use of fermented sludge as fertiliser leads to additional overall savings in primary energy because the equivalent of chemical fertilisers does not have to be produced, which for nitrogen fertiliser (Haber-Bosch process) is very energy intensive. The substitution of mineral fertilisers saves about 50 kWhprim/(person/year).

Anaerobic treatment of domestic sewage

The energy demand for aerobic wastewater treatment varies and depends on the system applied (about 50 kWhel/(person/year). Aeration requires 50% to 80% of the energy needed for aerobic wastewater treatment. Aerobic stabilisation requires five to six times more electricity than anaerobic stabilisation (reduction of organic pollution load measured as chemical oxygen demand). Electric power generation is linked to the emission of greenhouse gases (~0,6 kg CO2/kWhel). Wastewater aeration and chemical fertiliser production consume energy mainly based on fossil fuels, which increases CO2 emissions; anaerobic digestion reduces the climatic impact of wastewater handling by saving fossil resources.

Aerobic treatment plants lose nutrients to the atmosphere (nitrogen) or receiving water bodies (>90% of the potassium, >20% nitrogen, >5% phosphorus even in high performance systems), which leads to eutrophication of rivers, lakes and the sea. Another alarming aspect to nutrient loss is that fossil phosphorus (P) reserves may be depleted in about 70 years, so most P should be recycled. Technical methods for P recycling from sewage sludge are very energy- and chemicals-intensive, and cost up to 10 times as much as mining fossil P, according to 2002 market prices.

Increasingly, sludge generated in aerobic wastewater treatment plants is incinerated or disposed of in landfills instead of being applied as an economic crop fertiliser. More farmers are rejecting the application of such sludge to their land. Concerns over polluted sewage sludge have even resulted in the possibility of a legal ban in parts of Germany. The intermixing of municipal (domestic) and industrial wastewater streams in addition to rainwater from partly high-polluted surfaces, such as main streets and parking lots, is the chief cause of polluted sludge.

Separating these streams thus facilitates adapted treatment and appropriate use in agriculture. Rainwater should be percolated separately, if necessary having passed filtration treatment. Domestic wastewater can be split up into two fractions: greywater, which is effluent from washbasins and bath tubs, is least polluted and can be easily treated by e.g. reed beds or rotating immersion disk facilities. The remaining wastewater, so-called blackwater (effluent from toilets), makes up the smallest fraction of household wastewater but the most charged with organic material, nutrients, germs and other substances.

The separation of blackwater from other wastewater streams implies that its fermented sludge will be less polluted by harmful substances like heavy metals or other chemicals. Its nutrient contents can then be used more easily in agriculture. For these reasons, the mixing of wastewater streams should be avoided.

The problem of manure-intrinsic pollution like endocrine disrupters (hormones or substances having hormone-like effects) or pharmaceuticals must be taken into account. These substances may be more effectively destroyed by anaerobic treatment than aerobic treatment, but this should be subject to research in pilot facilities.

The practical implementation of blackwater separation can be facilitated through vacuum toilets, which use less than one litre per flush because of the transport medium being air instead of water. This important technical tool links the collection of blackwater in a concentrated form to large savings of flushing water, but other specially designed low-flush toilets are available. Such a system could be a valuable step to sustained growth in many parts of the world currently overtapped by drought and development, including the USA. Toilet flush water can be reduced to a minimum, energy can be gained from blackwater and biowaste, and the easily treatable, separated greywater can be re-used for gardening, cleaning and even washing.

Most experts today agree that a change from fossil fuels to renewable energy resources is necessary immediately. Fossil fuel resources are finite and their depletion restricts the development potential of future generations and accelerates climatic change. This global change is already leading to the rapid shrinking of glaciers worldwide, on which many countries and regions depend for a reliable freshwater supply, via rivers, in summer. Flush toilets are no model for regions already suffering from scarce water resources. Facing the climate chance-induced disappearance of glaciers in the next decades, a system that literally flushes these diminishing freshwater resources down toilets, will need to be replaced in more regions of the world.

The question "Will there be a future for biogas production from concentrated blackwater?" is not a technical one - the technology exists. Instead, it is a societal question. Will it be "business as usual" for the next 50 years, or is society willing to evolve, taking everything into account that affects the basis of its own future well being? Now is the time to deliberate on alternatives for a more sustainable future.

Authors' noteDipl.-Ing. Christine Nicklas, project assistant, and Dr. rer. nat. Helmut Lehn, project leader, work at the Centre for Technology Assessment in Stuttgart, Germany. For more information, contact the author by email at: [email protected]